Yes, you can braze stainless steel with MAPP gas, but only if you use the correct materials and technique. The success of the joint has less to do with the heat from your torch and everything to do with chemically removing the stubborn oxide layer on the steel's surface. Without the right flux, the filler metal will simply ball up and refuse to bond, no matter how hot you get the metal.

The challenge of brazing stainless steel is not a matter of temperature, as MAPP gas is more than hot enough. The critical factor is using a specialized high-temperature flux to dissolve the invisible layer of chromium oxide that otherwise prevents the filler metal from wetting the surface.

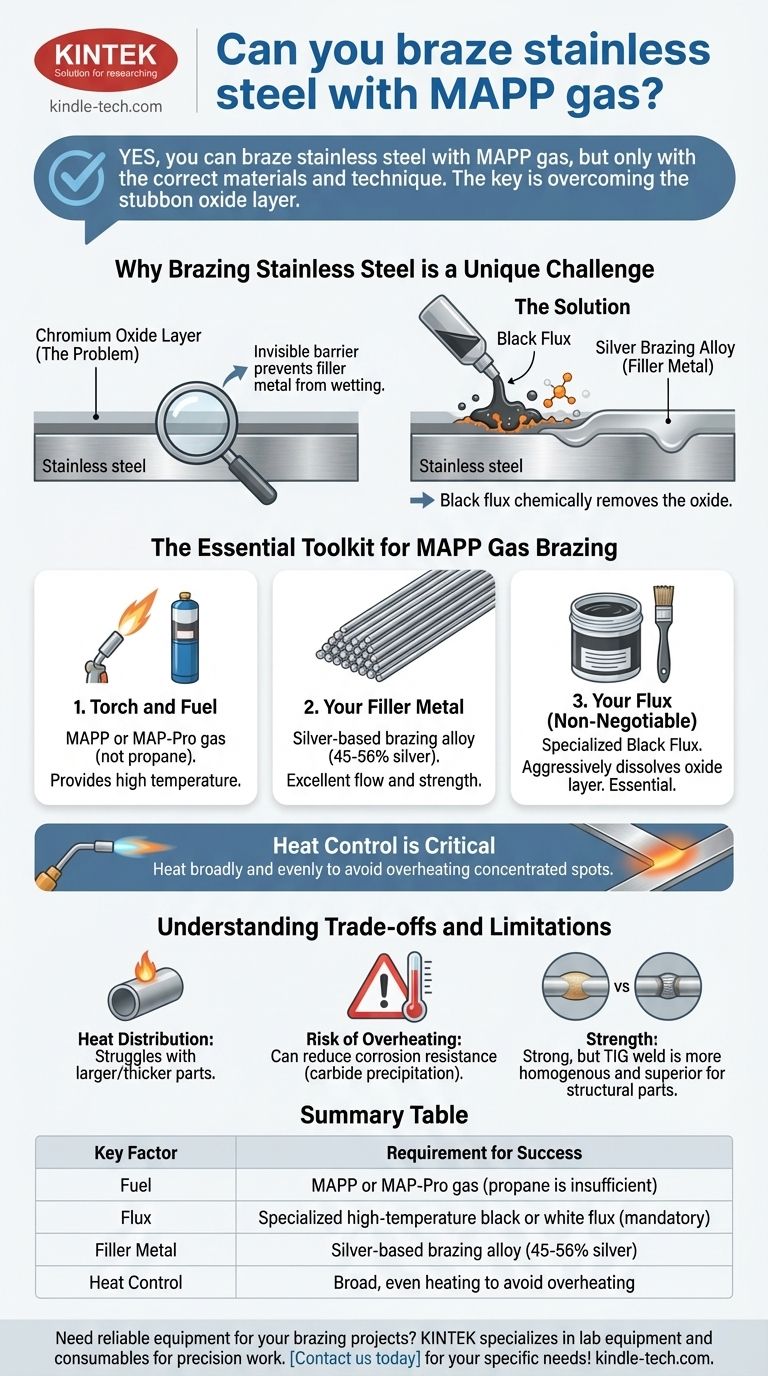

Why Brazing Stainless Steel Is a Unique Challenge

Joining stainless steel is fundamentally different from joining copper or mild steel. The very property that makes it "stainless"—its resistance to corrosion—is your primary obstacle.

The Problem: The Chromium Oxide Layer

Stainless steel protects itself from rust by forming an ultra-thin, tough, and transparent layer of chromium oxide on its surface the instant it's exposed to air.

This passive layer is highly resilient and has a much higher melting point than the brazing alloys you will use. It acts as a barrier, preventing the molten filler metal from making direct contact with the base metal.

The Solution: Specialized Brazing Flux

Standard plumbing flux is completely ineffective against chromium oxide. You must use a flux specifically formulated for brazing stainless steel.

These are typically sold as black flux or white flux. Black flux is the most common and effective choice, containing powerful chemical compounds that aggressively dissolve the chromium oxide layer at high temperatures, allowing the filler metal to flow.

The Role of Heat Control

Stainless steel is a relatively poor conductor of heat compared to copper. This means heat from your torch tends to stay concentrated in one spot instead of spreading evenly.

While MAPP gas provides ample heat, its focused flame can easily overheat a small area. Your goal is to heat the entire joint area broadly and evenly until it reaches the working temperature of your chosen filler metal.

The Essential Toolkit for MAPP Gas Brazing

Having the right tools is not optional for this process. Each component plays a critical role.

Your Torch and Fuel

A standard torch head with MAPP or MAP-Pro gas provides the necessary temperature, which is well above the melting point of silver-based brazing alloys. Propane is generally not hot enough to be effective, especially on anything but the smallest parts.

Your Filler Metal

The industry standard for strong, reliable stainless steel joints is a silver-based brazing alloy. Look for rods with a silver content between 45% and 56%. These alloys have excellent flow characteristics and create high-strength bonds.

Your Flux: The Non-Negotiable Component

This is the most critical part of your setup. You must acquire a black flux designed for brazing stainless steel with silver alloys. Apply it to both pieces of the joint before you start heating. The flux will turn clear and liquid when the steel reaches the correct brazing temperature, acting as a visual indicator.

Understanding the Trade-offs and Limitations

While MAPP gas brazing is possible, it is not always the ideal solution. You must understand its limitations compared to other methods like TIG welding.

Heat Distribution on Larger Parts

A single MAPP torch flame is relatively small. It will struggle to bring larger or thicker sections of stainless steel up to a uniform brazing temperature. The metal will lose heat to the surrounding air faster than your torch can supply it, causing the process to fail. This method is best suited for small parts, tubing, and thin sheets.

Risk of Overheating

The intense heat of a MAPP torch can easily overheat the stainless steel, especially in the hands of an inexperienced user. Overheating can cause a phenomenon called "carbide precipitation" or "sensitization," which can reduce the corrosion resistance of the steel in the area around the joint.

Strength Compared to a Welded Joint

A properly executed silver-brazed joint is very strong and is often stronger than the base metals in non-stainless applications. However, a TIG weld creates a more homogenous joint that fully preserves the properties of the stainless steel. For critical structural applications, welding is the superior method.

Making the Right Choice for Your Project

Use this guidance to determine if MAPP gas brazing is the right approach for your specific goal.

- If your primary focus is joining small parts, tubing, or thin sheets cost-effectively: MAPP gas brazing is an excellent and accessible method, as long as you use the mandatory black flux and silver alloy.

- If your primary focus is structural integrity on larger parts or maximum corrosion resistance: TIG welding is the more robust and professional solution, and you should seek out that process instead.

- If your primary focus is simply creating a bond stronger than soft solder: Brazing is a major step up, but be prepared for the learning curve associated with heat control and flux application on stainless steel.

With the right preparation and materials, MAPP gas can be an effective tool for joining stainless steel, bridging the gap between simple soldering and professional welding.

Summary Table:

| Key Factor | Requirement for Success |

|---|---|

| Fuel | MAPP or MAP-Pro gas (propane is often insufficient) |

| Flux | Specialized high-temperature black or white flux (mandatory) |

| Filler Metal | Silver-based brazing alloy (45-56% silver) |

| Heat Control | Broad, even heating to avoid overheating and carbide precipitation |

| Best For | Small parts, tubing, and thin sheets (not large structural pieces) |

Need reliable equipment for your brazing projects? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision tools and materials. Whether you're working with stainless steel or other metals, our expertise ensures you have the right supplies for strong, durable joints. Contact us today to discuss your specific application and how we can support your work!

Visual Guide

Related Products

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is vacuum furnace heat treatment? Achieve Superior, Contamination-Free Metal Strengthening

- How do you prevent vacuum leaks? A Proactive Strategy for System Integrity

- What is the process of carburizing? Achieve Superior Surface Hardening with Precision

- What is a pyrolysis furnace? A Tool for Converting Waste into Valuable Resources

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is the purpose of performing high vacuum heating treatment on titanium substrates? Ensure Superior Coating Adhesion

- Can hydrogen be produced from biomass? A Guide to Sustainable, Low-Carbon Hydrogen

- What is the quenching operation usually followed by? The Essential Tempering Process for Toughness