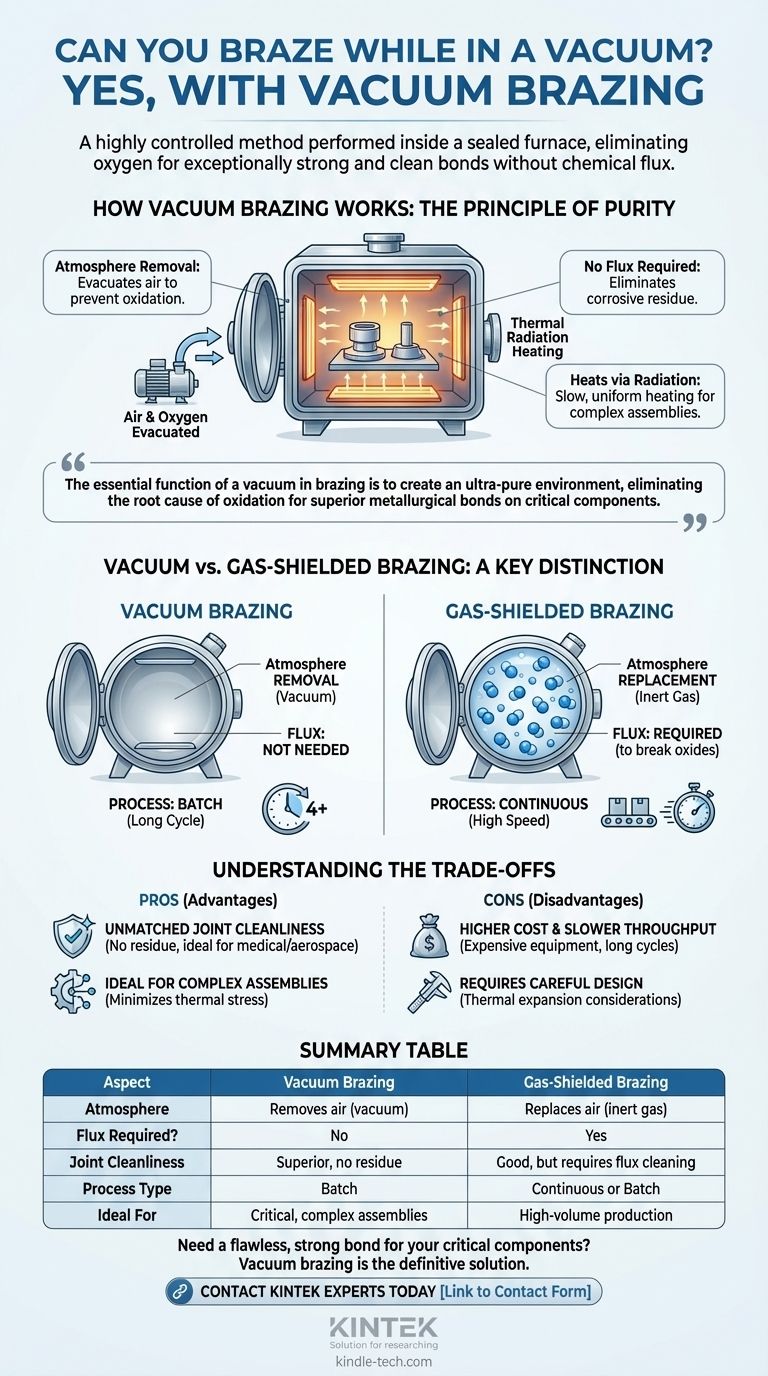

Yes, you can braze in a vacuum. This process, known as vacuum brazing, is a highly controlled method performed inside a sealed furnace. By removing oxygen and other reactive gases, the vacuum environment prevents oxidation and allows the filler metal to create an exceptionally strong and clean bond without the need for chemical flux.

The essential function of a vacuum in brazing is to create an ultra-pure environment. By removing the atmosphere rather than just replacing it, you eliminate the root cause of oxidation, allowing for superior metallurgical bonds on critical components.

How Vacuum Brazing Works: The Principle of Purity

Vacuum brazing is fundamentally different from conventional methods that rely on flux or a protective gas. It achieves a superior result by controlling the environment at a molecular level.

Removing the Problem: The Atmosphere

The primary purpose of the vacuum is to evacuate nearly all the air and water vapor from the furnace chamber. Oxygen is the main driver of oxidation on heated metal surfaces, which prevents the braze filler metal from properly wetting and bonding to the parent materials. A vacuum solves this by physically removing the oxygen.

An Environment Without Flux

Because the vacuum prevents the formation of oxides, chemical fluxes are not required. In some filler alloys, a small amount of magnesium is included. This magnesium acts as a "getter," vaporizing during the process to combine with any residual oxygen molecules, further purifying the joint.

Heating Through Radiation

In a vacuum, there is no air to transfer heat via convection. Therefore, heating is accomplished entirely through thermal radiation. The furnace's heating elements glow, radiating energy that is absorbed by the parts. This method allows for slow, uniform heating, which is critical for complex assemblies.

Vacuum vs. Gas-Shielded Brazing: A Key Distinction

To understand the value of vacuum brazing, it is helpful to compare it to a more common alternative: gas-shielded atmosphere brazing.

Atmosphere: Removal vs. Replacement

Vacuum brazing removes the atmosphere. Gas-shielded brazing, on the other hand, replaces the atmosphere, typically by purging the furnace with an inert gas like nitrogen to displace the oxygen. While effective, it doesn't achieve the same level of purity as a deep vacuum.

The Flux Dilemma: Not Needed vs. Required

This is the most significant operational difference. Vacuum brazing's clean environment makes flux unnecessary. Gas-shielded brazing, even with nitrogen protection, still requires the use of flux to break down stubborn surface oxides (like aluminum oxide, Al₂O₃).

The Process: Batch vs. Continuous

Vacuum brazing is a batch process. Parts are loaded, the furnace is sealed, a vacuum is pulled, and the heating/cooling cycle runs for several hours. In contrast, gas-shielded brazing can be a continuous process, with parts moving through a furnace on a conveyor belt at a much higher speed (e.g., 350mm/min).

Understanding the Trade-offs of Vacuum Brazing

Like any specialized process, vacuum brazing has distinct advantages and disadvantages that make it ideal for some applications and unsuitable for others.

Pro: Unmatched Joint Cleanliness

The absence of flux means there is no corrosive residue to clean off after brazing. This results in exceptionally clean joints, which is a non-negotiable requirement for medical implants, aerospace components, and sensitive electronic devices.

Pro: Ideal for Complex Assemblies

The slow, highly controlled heating and cooling cycles minimize thermal stress across the part. This makes vacuum brazing perfect for joining intricate shapes or dissimilar metals with different thermal expansion rates, preventing distortion and cracking.

Con: Higher Cost and Slower Throughput

Vacuum furnaces are expensive capital equipment, and the long cycle times (often 4+ hours per batch) make the process inherently slower and more costly than continuous atmosphere brazing. It is not designed for high-volume, low-cost manufacturing.

Con: Requires Careful Design

Because parts are heated slowly in a vacuum, differences in thermal expansion between dissimilar metals must be carefully calculated. The initial joint clearance at room temperature must be designed to achieve the perfect gap at the target brazing temperature.

Making the Right Choice for Your Application

Selecting the correct brazing method depends entirely on the technical requirements and commercial goals of your project.

- If your primary focus is maximum joint integrity and cleanliness for critical components: Vacuum brazing is the superior choice due to its flux-free process and superior bond quality.

- If your primary focus is high-volume production and cost-efficiency: Gas-shielded atmosphere brazing is often the more practical and economical solution.

Understanding the fundamental role of the atmosphere—whether it is removed or replaced—is the key to selecting the right brazing process for your specific engineering goal.

Summary Table:

| Aspect | Vacuum Brazing | Gas-Shielded Brazing |

|---|---|---|

| Atmosphere | Removes air (vacuum) | Replaces air (inert gas) |

| Flux Required? | No | Yes |

| Joint Cleanliness | Superior, no residue | Good, but requires flux cleaning |

| Process Type | Batch | Continuous or Batch |

| Ideal For | Critical, complex assemblies | High-volume production |

Need a flawless, strong bond for your critical components?

Vacuum brazing is the definitive solution for applications where joint integrity and cleanliness are paramount, such as in aerospace, medical, and electronics. KINTEK specializes in advanced thermal processing solutions, including vacuum brazing systems designed for precision and reliability.

Our expertise ensures your lab or production facility has the right equipment to achieve superior metallurgical bonds without compromise.

Contact our experts today to discuss how vacuum brazing can solve your specific metal-joining challenges.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the batch process for heat treating? A Guide to Flexible, Controlled Heat Treatment

- What is the role of high-temperature sintering furnaces in 3D solid electrolyte frameworks? Achieve Peak Performance

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- Why is a high vacuum brazing furnace essential for carbon-carbon to metal joints? Secure High-Purity Material Bonding

- How hot does a furnace heat exchanger get? Understand Safe Operating Temperatures to Prevent Hazards

- What is the function of the heat treatment process? Tailor Material Properties for Your Application

- What kind of furnace is used for casting? Choose the Right Heating Technology for Your Metal

- What is vacuum deposition of metal? Achieve Atomic-Level Coating Control for Superior Performance