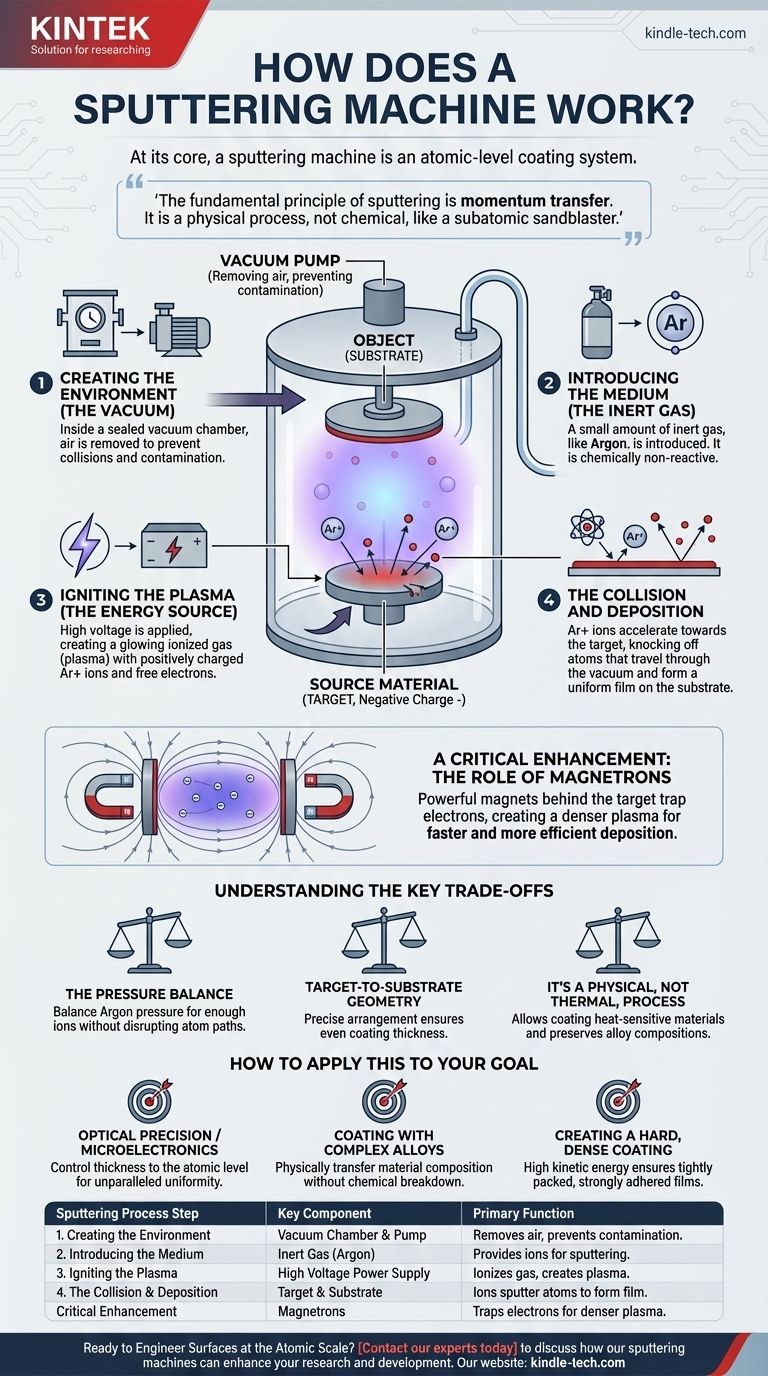

At its core, a sputtering machine is an atomic-level coating system. It uses a high-energy, ionized gas inside a vacuum to physically knock atoms off a source material, called a target. These dislodged atoms then travel and deposit onto an object, known as the substrate, forming an exceptionally thin and uniform film.

The fundamental principle of sputtering is momentum transfer. Unlike painting or dipping, it is not a chemical process. It is a physical one where energized gas ions act like a subatomic sandblaster, eroding a target and re-depositing that material, atom by atom, onto another surface with remarkable precision.

The Four Pillars of the Sputtering Process

To understand how a sputtering machine works, it is best to visualize the process in four distinct, sequential stages. Each stage is critical for achieving a high-quality thin film.

Step 1: Creating the Environment (The Vacuum)

The entire sputtering process takes place inside a sealed vacuum chamber. A pump actively removes air and other gases.

This vacuum is non-negotiable. It prevents the sputtered atoms from colliding with air molecules, which would otherwise contaminate the film and disrupt its path to the substrate.

Step 2: Introducing the Medium (The Inert Gas)

Once a vacuum is established, a small, precisely controlled amount of an inert gas is introduced. Argon is the most common choice.

Argon is used because it is chemically non-reactive and has a suitable atomic mass. Its job is not to react with the materials, but to become the "blasting" medium in the next step.

Step 3: Igniting the Plasma (The Energy Source)

A high voltage is applied within the chamber, creating a strong electric field. The target material is given a negative charge.

This energy strips electrons from the Argon gas atoms, creating a glowing, ionized gas known as a plasma. This plasma consists of positively charged Argon ions (Ar+) and free electrons.

Step 4: The Collision and Deposition

The positively charged Argon ions are now powerfully attracted to the negatively charged target. They accelerate towards it at high velocity.

Upon impact, the Argon ions transfer their kinetic energy and "sputter" atoms off the target material. These ejected target atoms travel through the vacuum and land on the substrate, slowly building up a uniform film.

A Critical Enhancement: The Role of Magnetrons

Modern sputtering systems are almost always magnetron sputtering systems. This enhancement dramatically improves the efficiency of the process.

Why Magnets Are a Game-Changer

Powerful magnets are placed behind the target. This magnetic field traps the free electrons from the plasma, concentrating them directly in front of the target's surface.

The Result: A Denser Plasma and Faster Sputtering

By trapping the electrons, the magnets significantly increase the probability that they will collide with and ionize more Argon atoms.

This creates a much denser, more intense plasma right where it is needed. More ions mean more collisions with the target, leading to a much faster and more stable deposition rate on the substrate.

Understanding the Key Trade-offs

Sputtering offers immense control, but it operates within a framework of critical balances and considerations. Understanding these is key to mastering the technology.

The Pressure Balance

While a deep vacuum is needed to ensure purity, some amount of Argon gas is required to create the plasma. Controlling this gas pressure is a delicate balance between having enough ions to sputter effectively and not so many that they interfere with the sputtered atoms' path.

The Target-to-Substrate Geometry

The distance, angle, and relative motion between the target and the substrate directly impact the final film's uniformity and thickness. Precise engineering is required to ensure every part of the substrate is coated evenly.

It's a Physical, Not Thermal, Process

Sputtering is a "cold" process compared to thermal evaporation. This allows for the coating of heat-sensitive materials like plastics. It also means that alloys and compounds can be deposited without altering their chemical composition, as the target is eroded layer by layer.

How to Apply This to Your Goal

The right approach depends entirely on the desired properties of the final film.

- If your primary focus is optical precision or microelectronics: The key is sputtering's ability to control film thickness down to the atomic level, ensuring unparalleled uniformity.

- If your primary focus is coating with complex alloys: Sputtering is ideal because it physically transfers the target material's composition directly to the substrate without breaking it down.

- If your primary focus is creating a hard, dense coating: The high kinetic energy of the sputtered atoms ensures the resulting film is tightly packed and strongly adhered to the substrate surface.

Ultimately, understanding these core mechanics allows you to leverage sputtering as a highly versatile and precise tool for engineering surfaces at the atomic scale.

Summary Table:

| Sputtering Process Step | Key Component | Primary Function |

|---|---|---|

| 1. Creating the Environment | Vacuum Chamber & Pump | Removes air to prevent contamination and allow clear atom paths. |

| 2. Introducing the Medium | Inert Gas (e.g., Argon) | Provides ions that will be accelerated to sputter the target material. |

| 3. Igniting the Plasma | High Voltage Power Supply | Ionizes the gas, creating a plasma of positive ions and free electrons. |

| 4. The Collision & Deposition | Target (Cathode) & Substrate | Ions sputter target atoms, which travel and form a thin film on the substrate. |

| Critical Enhancement | Magnetrons | Magnets trap electrons, creating a denser plasma for faster, more efficient deposition. |

Ready to Engineer Surfaces at the Atomic Scale?

KINTEK specializes in advanced sputtering equipment and consumables designed for the precise needs of laboratories. Whether your goal is optical precision, microelectronics fabrication, or creating hard, durable coatings, our solutions deliver the uniformity, control, and reliability you require.

Contact our experts today to discuss how our sputtering machines can enhance your research and development.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Spark Plasma Sintering Furnace SPS Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the function of a laboratory orbital shaker in methylene blue adsorption kinetics? Optimize Your Research

- What is the voltage for arcing? It's Not a Single Number—It's About Electric Field Strength

- What is the mechanism of RF sputtering? Unlock the Power to Deposit Insulating Materials

- How does an industrial-grade DC regulated power supply function in indium deposition? Achieve Industrial Precision

- What is the fast pyrolysis method? A Rapid Process for Converting Biomass to Bio-Oil

- What are the specific requirements for incubation equipment used in the bioleaching of enargite? Ensure High-Performance Results

- What is the necessity of a low-temperature drying step in Cu-TiO2 thin film preparation? Ensure Structural Integrity

- What is bio-oil produced by pyrolysis? A Renewable Fuel Alternative Explained