In advanced manufacturing and research, a sputtering system is a highly precise vacuum technology used to deposit ultra-thin films of material onto a surface, or substrate. The process works by creating an energized plasma that bombards a source material, known as a target, knocking atoms loose which then travel and coat the substrate. This physical, non-thermal process allows for the creation of exceptionally pure, dense, and strongly bonded layers on an atomic scale.

Sputtering is not simply a coating method; it is a foundational fabrication technique for creating high-performance materials. Its core value lies in its unparalleled control over film thickness, purity, and adhesion, making it essential for producing everything from microchips to advanced optical lenses.

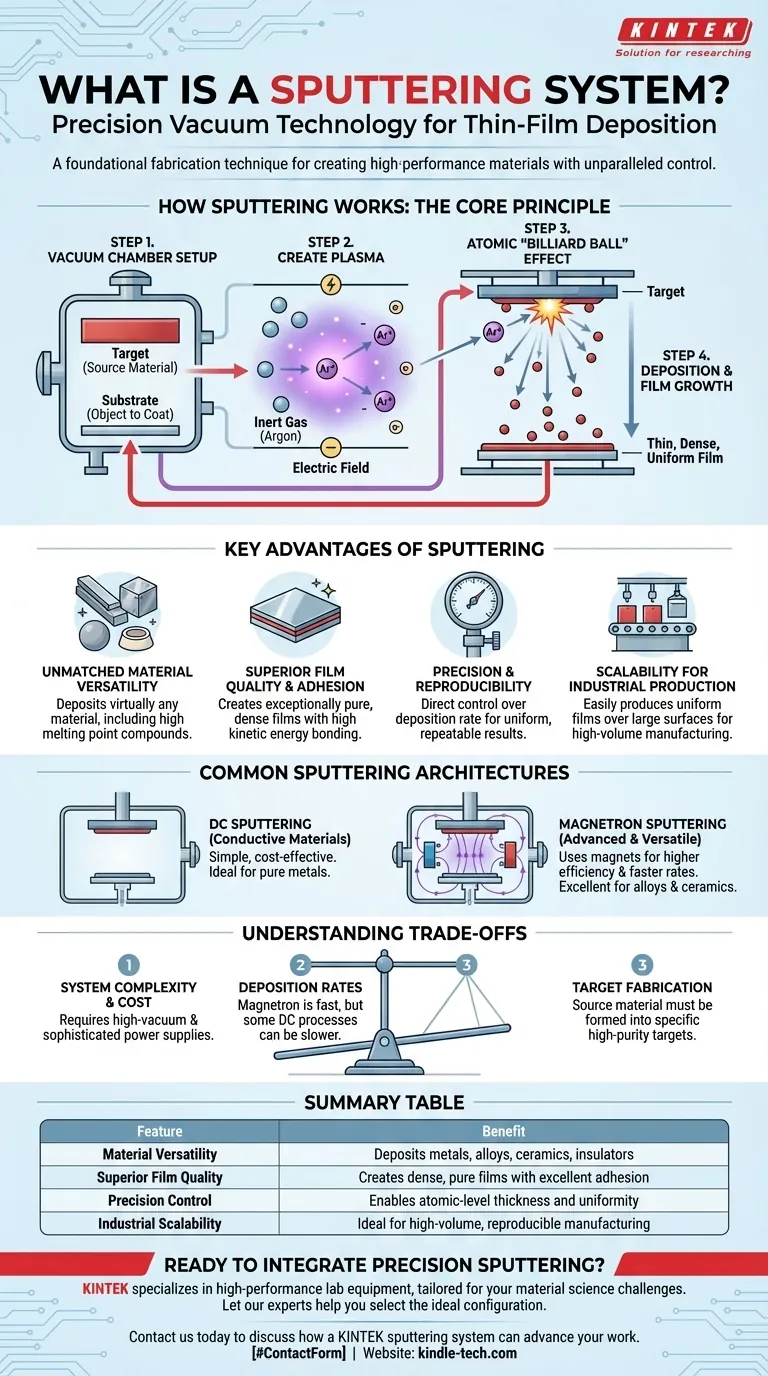

How Sputtering Works: The Core Principle

Sputtering is a physical vapor deposition (PVD) process. Unlike thermal evaporation, which boils a material, sputtering uses momentum transfer to physically eject atoms from a source.

The Target and Substrate

The process takes place inside a vacuum chamber containing two key components. The target is a solid block of the material you wish to deposit, while the substrate is the object you want to coat.

Creating the Plasma

The chamber is filled with a small amount of an inert gas, typically Argon. A strong electric field is applied, which strips electrons from the Argon atoms, creating an ionized gas or plasma composed of positive Argon ions and free electrons.

The Atomic "Billiard Ball" Effect

The positively charged Argon ions are accelerated by the electric field and slam into the negatively charged target. This high-energy collision physically knocks atoms or molecules loose from the target material, a process analogous to a cue ball breaking a rack of billiard balls.

Deposition and Film Growth

These ejected target atoms travel through the vacuum chamber and land on the substrate. As they accumulate, they form a thin, uniform, and highly dense film with exceptional adhesion, a direct result of the high kinetic energy of the arriving atoms.

Key Advantages of Sputtering Technology

Sputtering is widely adopted in high-tech industries because the films it produces have superior qualities that are difficult to achieve with other methods.

Unmatched Material Versatility

Virtually any material can be deposited via sputtering. This includes pure metals, alloys, semiconductors, and even insulators and complex compounds like ceramics that have extremely high melting points.

Superior Film Quality and Adhesion

The high energy of the sputtered atoms ensures they form a very dense, pure film with few defects or pinholes. This energy also helps them bond tenaciously to the substrate, creating a durable and long-lasting coating.

Precision and Reproducibility

The deposition rate is directly controlled by the electrical current applied to the target. This allows for extremely precise control over film thickness, ensuring that processes are highly uniform and repeatable from one run to the next.

Scalability for Industrial Production

Sputtering can easily produce uniform films over very large surface areas. This, combined with its reproducibility and fast coating rates in modern systems, makes it perfectly suited for high-volume, high-efficiency industrial manufacturing.

Common Sputtering Architectures

While the core principle remains the same, different sputtering configurations are used to optimize the process for specific materials and applications.

DC Sputtering

Direct Current (DC) sputtering is the simplest and most cost-effective form. It works exceptionally well for depositing electrically conductive materials, such as pure metals. Its straightforward nature makes it a workhorse for applications requiring basic metallic coatings on a large scale.

Magnetron Sputtering

Magnetron sputtering is a more advanced technique that uses powerful magnets behind the target. These magnets trap electrons near the target's surface, dramatically increasing the efficiency of the plasma and leading to much faster deposition rates. This method is highly versatile and can be used for a wide range of materials, including alloys and ceramics.

Understanding the Trade-offs

While powerful, sputtering is not the right solution for every problem. Understanding its limitations is key to using it effectively.

System Complexity and Cost

Sputtering systems require a high-vacuum environment and sophisticated power supplies. This makes them inherently more complex and expensive to purchase and maintain compared to simpler coating methods like electroplating or thermal evaporation.

Deposition Rates

While magnetron sputtering is quite fast, some DC sputtering processes can be slower than other deposition techniques. For applications where speed is the only concern and film quality is secondary, other methods might be more efficient.

Target Fabrication

The source material must be formed into a high-purity target of a specific size and shape to fit the system. For exotic or custom alloy materials, fabricating a suitable target can add cost and lead time to a project.

How to Apply This to Your Project

Choosing the right deposition technology depends entirely on the required properties of the final film.

- If your primary focus is cost-effective coating of pure metals: A DC sputtering system provides a simple, reliable, and high-quality solution.

- If your primary focus is high performance, alloys, or insulating compounds: Magnetron sputtering offers the necessary speed, material flexibility, and process control.

- If your primary focus is industrial-scale production with high uniformity: Sputtering's excellent reproducibility and ability to coat large areas make it a superior choice.

Ultimately, a sputtering system offers unparalleled control over the atomic-level construction of surfaces, enabling the creation of advanced materials from the ground up.

Summary Table:

| Feature | Benefit |

|---|---|

| Material Versatility | Deposits metals, alloys, ceramics, and insulators |

| Superior Film Quality | Creates dense, pure films with excellent adhesion |

| Precision Control | Enables atomic-level thickness and uniformity |

| Industrial Scalability | Ideal for high-volume, reproducible manufacturing |

Ready to integrate precision sputtering into your research or production?

KINTEK specializes in high-performance lab equipment, including sputtering systems tailored for your specific material science and fabrication challenges. Our experts can help you select the ideal configuration—from cost-effective DC sputtering for metals to advanced magnetron sputtering for complex compounds—ensuring you achieve the film quality, adhesion, and scalability your projects demand.

Contact us today to discuss how a KINTEK sputtering system can advance your work. #ContactForm

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the different melting methods? A Guide to Choosing the Right Industrial Furnace

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What are sputtering systems used for? A Guide to Advanced Thin-Film Deposition

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is RF magnetron sputtering? A Guide to Depositing Insulating Thin Films