Yes, not only can you braze under a vacuum, but it is a highly advanced and precise method for creating exceptionally strong and clean joints. This process, known as vacuum brazing, uses a specialized furnace to remove oxygen and other reactive gases from the environment. By eliminating the atmosphere, the process prevents oxidation during heating and removes the need for chemical fluxes.

Vacuum brazing is a strategic choice for high-performance applications where joint integrity and cleanliness are non-negotiable. It leverages a vacuum to create a pristine environment, producing flux-free joints that are often stronger and more reliable than those made by other methods.

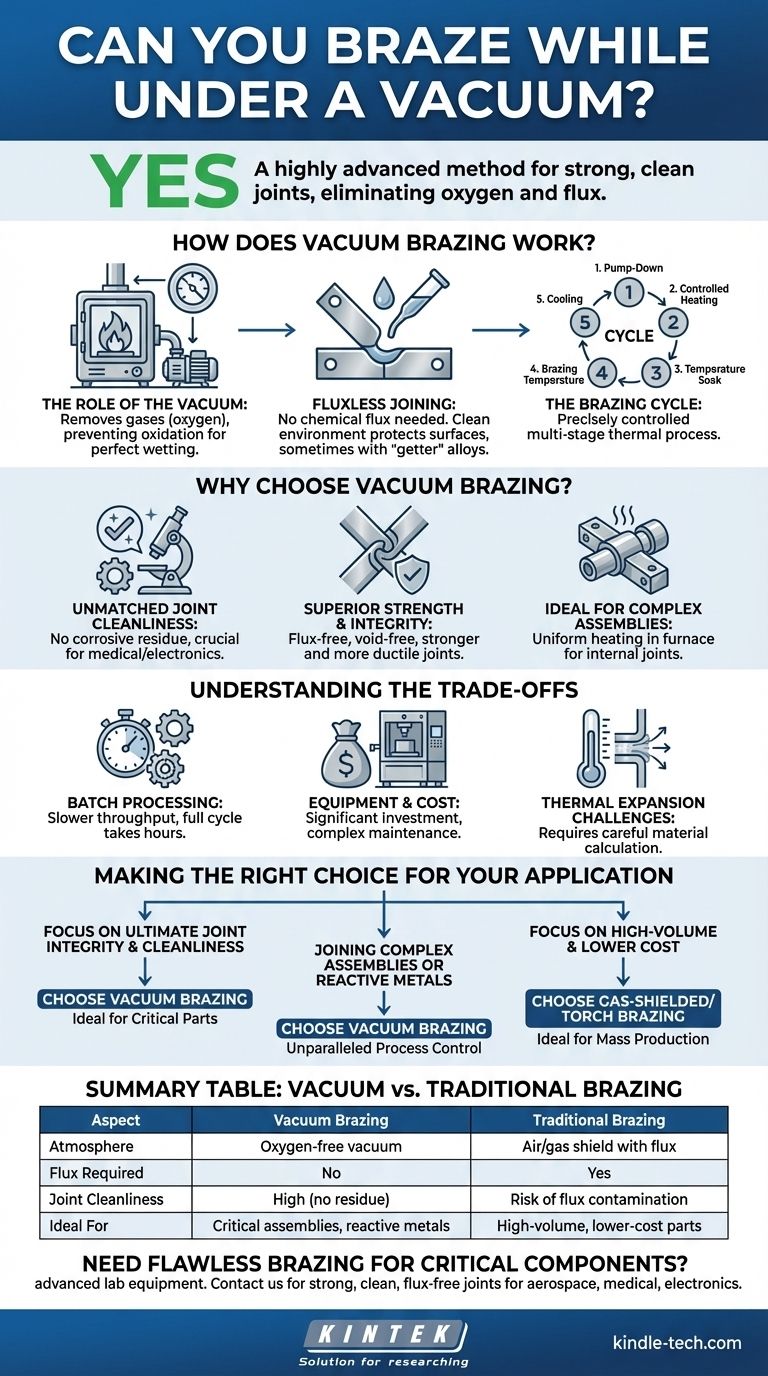

How Does Vacuum Brazing Work?

Vacuum brazing is a thermally controlled process that relies on the environment within a furnace to do the work that fluxes and torches would do in a conventional setting.

The Role of the Vacuum

The primary function of the vacuum is to remove atmospheric gases, especially oxygen, from the brazing chamber. When metals are heated, they react rapidly with oxygen to form oxides on the surface. These oxide layers prevent the molten brazing filler metal from wetting and bonding with the parent materials, leading to a weak or failed joint.

By evacuating the furnace, this entire oxidation process is virtually eliminated.

Fluxless Joining

In traditional brazing, a chemical flux is applied to the joint to dissolve oxides and protect the surfaces during heating. A major advantage of vacuum brazing is that no flux is required.

The clean, inert environment of the vacuum performs the protective function. Some filler alloys used in vacuum brazing also contain trace elements like magnesium, which act as a "getter," bonding with any residual oxygen molecules to ensure a perfectly clean surface.

The Brazing Cycle

A typical vacuum brazing cycle is a carefully controlled, multi-stage process:

- Pump-Down: The furnace is sealed and air is evacuated to a specific vacuum level.

- Controlled Heating: The assembly is heated at a controlled rate using thermal radiation, as convection and conduction are not effective in a vacuum.

- Temperature Soak: The parts are held at an intermediate temperature to ensure the entire assembly reaches a uniform temperature, which is critical for complex geometries.

- Brazing Temperature: The temperature is raised to the filler metal's melting point, allowing it to flow into the joint via capillary action.

- Cooling: The assembly is cooled in a controlled manner to complete the process.

Why Choose Vacuum Brazing?

While more complex than other methods, vacuum brazing offers distinct advantages that make it essential for critical applications.

Unmatched Joint Cleanliness

The elimination of flux means there is no corrosive residue left on the part after brazing. This is critical for components used in medical devices, electronics, and aerospace, where post-braze cleaning can be difficult and any remaining residue could cause failure.

Superior Strength and Integrity

Because there is no flux, there is no risk of flux being trapped within the joint. Flux inclusions create voids that weaken the bond. Vacuum-brazed joints are consistently stronger, more ductile, and less prone to failure.

Ideal for Complex Assemblies

Heating an entire assembly uniformly within a furnace ensures that all joints, even those in hard-to-reach internal areas, reach the correct temperature simultaneously. This is something that is nearly impossible to achieve with a localized heat source like a torch.

Understanding the Trade-offs

Vacuum brazing is a powerful technique, but it is not the right solution for every situation. Understanding its limitations is key to making an informed decision.

Batch Processing vs. Continuous Flow

Vacuum brazing is a batch process. A full cycle can take several hours per furnace load, which limits throughput. In contrast, methods like gas-shielded brazing can operate continuously, making them better suited for high-volume manufacturing where speed is a priority.

Equipment and Cost

A vacuum furnace represents a significant capital investment. The machinery is complex and requires specialized maintenance and operation, making the barrier to entry much higher than for conventional brazing methods.

Thermal Expansion Challenges

Because the entire assembly is heated and cooled, differences in the coefficient of thermal expansion between dissimilar materials must be carefully calculated. The joint gap that is perfect at room temperature might close up or become too wide at brazing temperature, compromising the joint.

Making the Right Choice for Your Application

Selecting the right brazing method depends entirely on the requirements of the final product.

- If your primary focus is ultimate joint integrity and cleanliness for critical parts: Vacuum brazing is the superior choice, as it eliminates flux, prevents oxidation, and produces void-free joints.

- If your primary focus is high-volume production and lower cost: A continuous process like gas-shielded or torch brazing may be more suitable for your economic and throughput goals.

- If you are joining complex assemblies or reactive metals like titanium: The uniform heating and controlled atmosphere of a vacuum furnace offer unparalleled advantages and process control.

Ultimately, choosing vacuum brazing is an investment in a process that delivers exceptional quality and reliability where performance cannot be compromised.

Summary Table:

| Aspect | Vacuum Brazing | Traditional Brazing |

|---|---|---|

| Atmosphere | Oxygen-free vacuum | Air or gas shield with flux |

| Flux Required | No | Yes |

| Joint Cleanliness | High (no residue) | Risk of flux contamination |

| Ideal For | Critical assemblies, reactive metals | High-volume, lower-cost parts |

Need flawless brazing for critical components? KINTEK specializes in advanced lab equipment, including vacuum brazing solutions tailored for aerospace, medical, and electronics industries. Our expertise ensures strong, clean joints without flux—perfect for high-performance applications. Contact us today to discuss how we can enhance your brazing process!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is oxidation in brazing? How to prevent it for strong, durable joints

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining