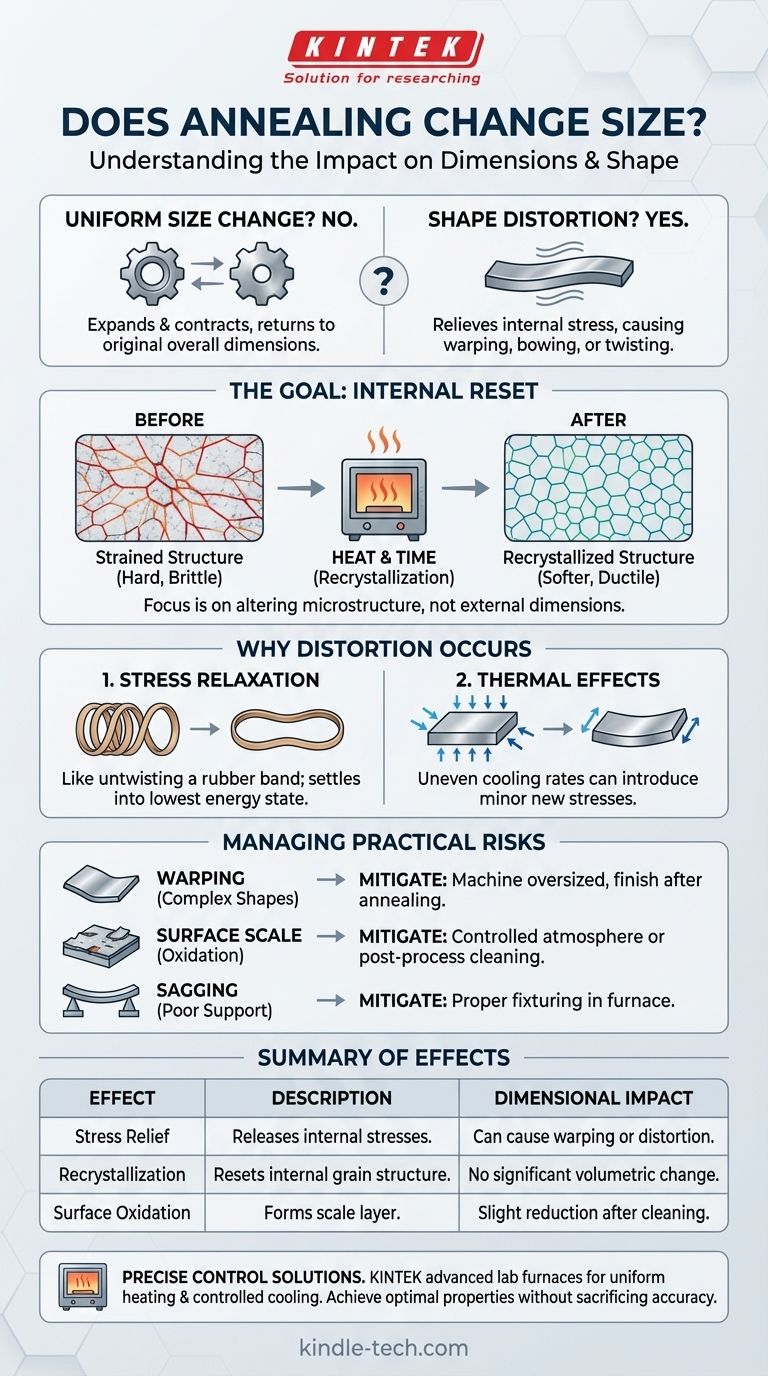

In practice, annealing does not cause a significant, uniform change in a metal part's overall size. While the part will expand when heated and contract when cooled, it should return to its original dimensions. However, the process can cause minor changes in shape—such as warping or distortion—as internal stresses within the material are relieved.

The core purpose of annealing is to alter a material's internal microstructure to make it softer and more ductile, not to change its external dimensions. Any change in size is a secondary effect, typically manifesting as distortion from the release of locked-in stress, rather than uniform growth or shrinkage.

The Goal of Annealing: Internal Reset, Not External Change

Annealing is fundamentally a heat treatment process designed to "reset" the metal's internal crystal structure. This is done to reverse the effects of processes like cold working, forming, or welding.

What is Internal Stress?

When metal is bent, stretched, or machined, its internal crystalline structure becomes strained and filled with defects. This stored energy, known as internal stress, makes the material harder, more brittle, and more susceptible to cracking.

The Mechanism of Recrystallization

Heating the metal to its annealing temperature gives the atoms enough energy to move. They rearrange themselves from a strained, high-energy state into a more orderly, low-energy lattice. The reference to "defects...repair themselves" is describing this recrystallization process.

The Result: A Softer, More Workable Material

After being held at temperature and then slowly cooled, the metal's internal structure is more uniform and stress-free. This makes the material significantly more ductile (able to be stretched or formed without breaking) and less hard.

Why Minor Dimensional Changes Can Occur

While the part's volume doesn't change, its shape can. This is the critical distinction for any application with tight tolerances. The change is not a predictable shrinkage or growth but a relaxation into a new, stress-free shape.

The Primary Cause: Stress-Induced Distortion

Imagine a twisted rubber band. It holds its shape due to stored energy. When you gently heat it, it untwists and relaxes. A metal part with internal stress behaves similarly. During annealing, as the stress is relieved, the part may warp, bow, or twist slightly to settle into its lowest energy state.

The Role of Thermal Expansion

All materials expand when heated and contract when cooled. If a part has uneven thickness or is cooled non-uniformly, different sections will contract at different rates. This can introduce new, albeit much lower, stresses and contribute to minor distortion. The slow cooling specified in annealing is designed to minimize this effect.

Understanding the Practical Risks

For an engineer or machinist, the main concern with annealing is not a uniform size change but the loss of dimensional accuracy due to these secondary effects.

The Risk of Warping

Parts with complex shapes, thin walls, or significant asymmetry are most susceptible to warping. The more internal stress a part has before annealing, the more it is likely to move during the process.

Surface Oxidation (Scale)

Heating metal in the presence of oxygen causes a layer of oxide, or scale, to form on the surface. This scale can be several thousandths of an inch thick and must often be removed through chemical cleaning (pickling) or abrasive methods, which can affect the final surface finish and dimensions.

The Need for Proper Support

At high annealing temperatures, metal loses a significant amount of its strength. If a long or heavy part is not properly supported in the furnace, it can sag under its own weight, causing permanent deformation.

Making the Right Choice for Your Process

Controlling dimensional stability during annealing is about planning your manufacturing sequence correctly.

- If your primary focus is maintaining tight tolerances: The standard practice is to machine the part slightly oversized, perform the annealing process to relieve stress, and then conduct a final, light machining pass to achieve the precise final dimensions.

- If your primary focus is simply stress-relieving a non-critical part: The minor potential for distortion is likely acceptable and may not require post-process machining.

- If you are working with very thin or complex parts: Ensure the part is fixtured and fully supported in the furnace to prevent sagging, and consult a metallurgist about the optimal cycle to minimize distortion.

By understanding annealing as a process of stress relaxation rather than volumetric change, you can strategically control your manufacturing steps to ensure final part accuracy.

Summary Table:

| Effect of Annealing | Description | Impact on Dimensions |

|---|---|---|

| Stress Relief | Releases internal stresses from cold working or forming. | Can cause warping or distortion, not uniform size change. |

| Recrystallization | Resets the internal grain structure to a softer state. | No significant volumetric change; part should return to original size after heating/cooling cycle. |

| Surface Oxidation | Forms a layer of scale that must be removed. | Can slightly reduce dimensions after post-treatment cleaning. |

Need precise control over your annealing process to prevent warping and ensure dimensional stability? KINTEK specializes in advanced lab furnaces and consumables designed for uniform heating and controlled cooling cycles. Our equipment helps laboratories and manufacturers achieve optimal material properties without sacrificing part accuracy. Contact our experts today to discuss your specific application and ensure your heat treatment process delivers consistent, reliable results.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Is heat transfer possible in vacuum? Yes, and Here’s How It Works

- What technical advantages does a penetrating vacuum chromizing unit offer? Rapid 3-5 Minute Tube Diffusion Processing

- What is the principle of sintering process? Transforming Powder into High-Performance Solids

- What is the role of a vacuum drying oven in PEO-based membrane treatment? Achieve Peak Solid-State Battery Purity

- What are high temperature furnaces made of? Graphite vs. Refractory Metals Explained

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- Can you solder or braze stainless steel? Yes, with the right preparation and methods.

- How long does it take to anneal metal? From minutes to days for perfect results.