Yes, brazing is a highly effective method for joining stainless steel. However, it requires specific techniques to overcome the material's inherent resistance to being "wetted" by filler metals. The success of the operation hinges on properly managing the tough, passive oxide layer that gives stainless steel its corrosion-resistant properties.

The core challenge of brazing stainless steel is not the steel itself, but its protective chromium oxide surface. To create a strong bond, this oxide layer must be either chemically removed with flux or prevented from forming altogether using a controlled atmosphere, such as a vacuum.

The Core Challenge: The Chromium Oxide Layer

Stainless steel's defining characteristic is its "passive layer," a microscopic film of chromium oxide that forms instantly when the metal is exposed to oxygen. This layer is what makes the material resistant to rust and corrosion.

Why This Layer is a Problem

This same protective layer that prevents corrosion also acts as a barrier to the brazing process. It prevents the molten filler metal from making direct contact with the base stainless steel.

The Principle of "Wetting"

For a braze to be successful, the liquid filler alloy must wet the surfaces of the parts being joined. Wetting is the ability of the liquid to flow over and adhere to a solid surface, similar to how water spreads on clean glass but beads up on a waxed car. Without proper wetting, the filler metal will not bond, and the joint will fail.

Methods for Successfully Brazing Stainless Steel

To achieve a strong brazed joint on stainless steel, the chromium oxide layer must be dealt with. This is typically accomplished in one of two ways: using a chemical flux or controlling the atmosphere.

Using Flux

For brazing in open air, a chemical flux is applied to the joint. As the parts are heated, the flux becomes active, dissolving the chromium oxide layer and protecting the surface from re-oxidizing. This allows the molten braze alloy to wet the clean steel underneath.

Using a Controlled Atmosphere

For higher-quality or production-scale work, furnace brazing is often used. This process takes place inside a sealed furnace where the atmosphere can be precisely controlled to prevent oxidation from occurring in the first place.

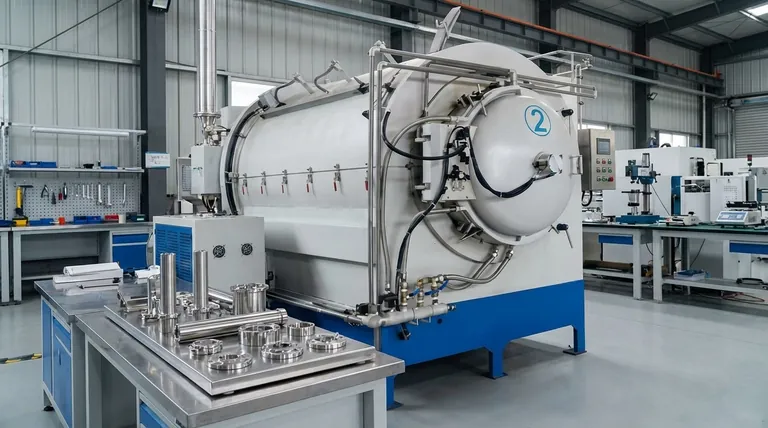

The Role of Vacuum Brazing

Vacuum brazing is a particularly effective form of furnace brazing for stainless steel. By removing almost all the air from the furnace chamber, there is no oxygen available to form oxides. The combination of high heat and high vacuum helps to break down and remove any existing oxides, resulting in exceptionally clean and strong joints.

Understanding the Trade-offs

Choosing the right method depends on your specific application, budget, and quality requirements. Each approach has distinct advantages and disadvantages.

Flux Brazing: Pros and Cons

Flux is effective and requires less specialized equipment than furnace brazing. However, it can become entrapped in the joint, potentially causing corrosion later. Post-braze cleaning to remove all residual flux is absolutely critical.

Vacuum Brazing: Pros and Cons

Vacuum brazing produces superior, aesthetically pleasing joints with no risk of flux contamination. The process is highly repeatable for batch production. The primary downside is the significant investment in specialized vacuum furnace equipment.

Critical Preparation Steps

Regardless of the brazing method you choose, proper surface preparation is non-negotiable for achieving a strong bond on stainless steel.

Mechanical Cleaning

The process often begins with mechanical cleaning, such as sandblasting or shot blasting. This aggressively removes the thickest parts of the oxide layer and creates a rougher surface texture that can aid in wetting.

Chemical Cleaning

After mechanical cleaning, parts must be chemically degreased to remove any oils, grease, or other contaminants. This is commonly done using solvents like acetone or through vapor degreasing with agents like trichloroethylene.

Making the Right Choice for Your Application

Selecting the correct brazing strategy comes down to balancing the requirements of the final product with available resources.

- If your primary focus is high-strength, visually clean joints for batch production: Vacuum furnace brazing is the superior choice, as it prevents oxidation and eliminates the need for post-braze cleaning.

- If your primary focus is one-off repairs or applications with less stringent aesthetic requirements: Torch brazing with an appropriate flux can be a perfectly viable and more accessible method.

- If your primary focus is maximizing joint integrity above all else: Meticulous surface preparation through both mechanical and chemical cleaning is the most critical factor, regardless of your chosen heating method.

Ultimately, successfully brazing stainless steel is entirely achievable once you understand that managing its protective oxide layer is the key to a perfect bond.

Summary Table:

| Method | Key Requirement | Best For |

|---|---|---|

| Flux Brazing | Chemical removal of oxide layer | Repairs, lower-volume jobs |

| Vacuum Brazing | Oxygen-free atmosphere | High-strength, batch production |

Achieve flawless stainless steel brazing results with KINTEK.

Brazing stainless steel requires precision and the right equipment to overcome its tough oxide layer. Whether your laboratory needs rely on flux-based methods for flexibility or the superior quality of vacuum brazing for production, KINTEK has the expertise and equipment to meet your specific joining challenges.

We specialize in providing reliable lab equipment and consumables that ensure strong, clean, and corrosion-resistant brazed joints every time. Let our solutions enhance your lab's efficiency and output quality.

Contact KINTEK today to discuss your stainless steel brazing needs and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance