Yes, absolutely. Heat treatment is one of the most powerful methods for intentionally altering a material's conductivity. By changing the temperature and cooling rate, you fundamentally rearrange the material's internal atomic structure, which in turn dictates how easily electrons (for electrical conductivity) or phonons (for thermal conductivity) can travel through it.

The core principle is that conductivity is a direct function of a material's internal order. Heat treatments that increase order and reduce internal obstacles will increase conductivity, while treatments that create disorder and introduce obstacles will decrease it, often in a trade-off for mechanical strength.

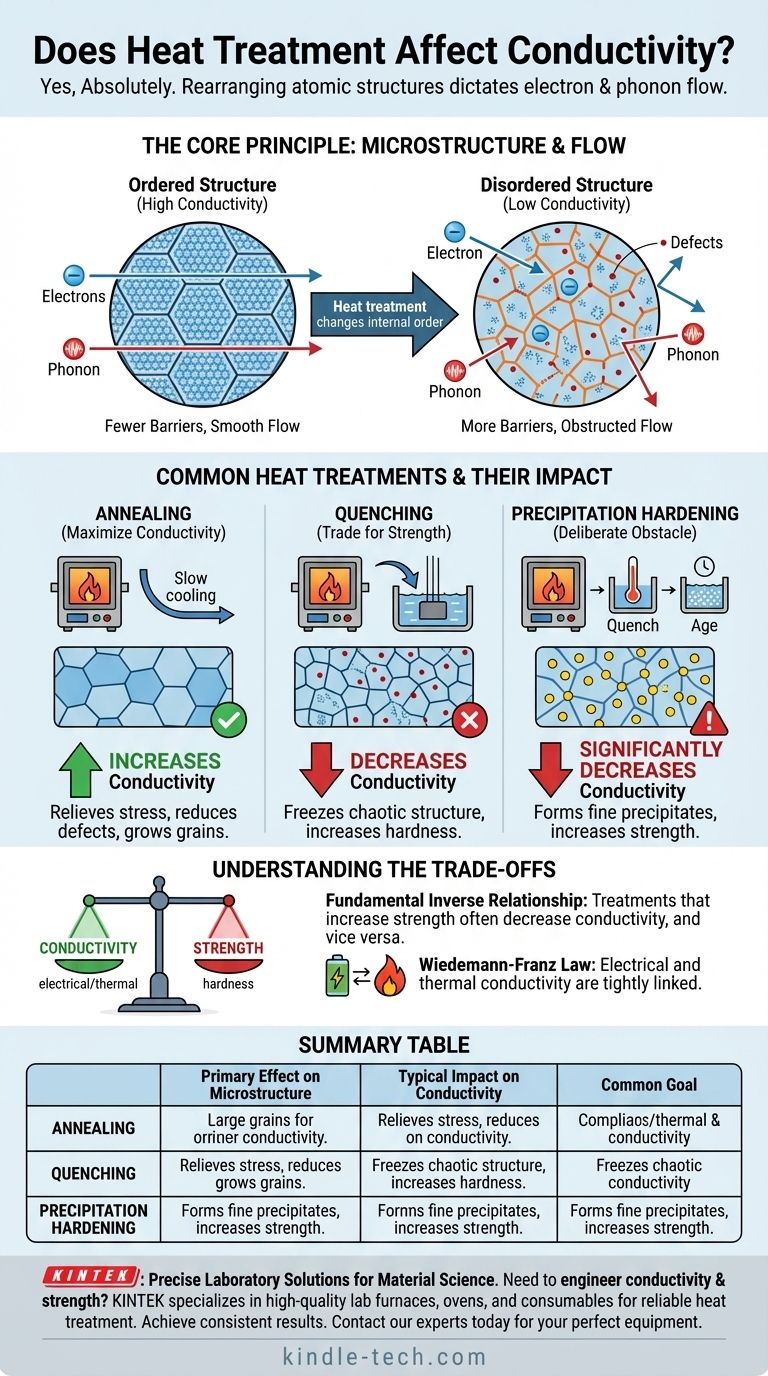

The Core Principle: Microstructure and Flow

To understand how heat treatment works, you must first understand what it is you're changing. The properties of a metal are not defined by its chemical composition alone, but by its microstructure—the arrangement of its atoms, crystals, and defects.

What is Conductivity?

Conductivity, both electrical and thermal, is a measure of how easily energy can move through a material. For electrical conductivity, this means the unimpeded flow of electrons. For thermal conductivity in metals, it involves the flow of both electrons and atomic vibrations called phonons.

Anything that scatters or obstructs this flow reduces conductivity.

How Heat Treatment Changes the Game

Heat treatment uses controlled heating and cooling to manipulate the size, shape, and arrangement of a material's internal features. These changes directly create or remove obstacles to electron and phonon flow.

The primary features affected are crystal grains, defects, and precipitates.

The Role of Crystal Grains

Metals are made of crystalline regions called grains. The junction between two grains is a grain boundary, which acts as a barrier that scatters electrons and reduces conductivity.

Treatments that result in larger, more uniform grains will have fewer boundaries, leading to higher conductivity. Treatments that create smaller, finer grains will have many more boundaries, leading to lower conductivity.

Defects and Impurities

Atomic-level imperfections, such as vacancies (missing atoms), dislocations (mismatched planes of atoms), and dissolved impurity atoms, disrupt the perfect crystal lattice. Each of these defects acts as a scattering point for electrons.

Heat treatments can either reduce the number of these defects or intentionally introduce them to achieve other properties.

Common Heat Treatments and Their Impact

Different heat treatments are designed to produce specific microstructures. Their effect on conductivity is a direct and predictable consequence of these changes.

Annealing: The Path to Higher Conductivity

Annealing involves heating a metal to a specific temperature and then cooling it very slowly. This process relieves internal stresses, reduces the number of dislocations, and allows the crystal grains to grow larger.

By removing obstacles and reducing grain boundaries, annealing is the primary method used to maximize both electrical and thermal conductivity. This is why high-purity copper used for electrical wiring is typically in an annealed state.

Quenching: Trading Conductivity for Strength

Quenching is the opposite of annealing. The material is heated and then cooled rapidly, often by plunging it into water or oil.

This rapid cooling freezes the chaotic high-temperature structure in place, trapping a high number of defects and creating a very fine, stressed grain structure. These numerous obstacles significantly decrease conductivity but dramatically increase hardness and strength.

Precipitation Hardening: A Deliberate Obstacle Course

Also known as age hardening, this is a sophisticated two-step process common in aluminum, copper, and nickel alloys. The material is first heated and quenched, then held at a lower temperature for an extended period (aging).

During aging, atoms of the alloying elements cluster together to form tiny, hard particles called precipitates within the metal's crystal structure. These precipitates are highly effective at blocking dislocations (increasing strength) but are also major scattering centers for electrons, causing a significant drop in conductivity.

Understanding the Trade-offs

You cannot choose a heat treatment without considering its impact on other properties. The relationship between conductivity and mechanical strength is the most critical trade-off to manage.

The Inevitable Balance: Conductivity vs. Strength

There is a fundamental inverse relationship between a metal's conductivity and its strength.

Treatments that make a metal stronger (like quenching or precipitation hardening) do so by creating microstructural features that impede motion. These same features also impede the flow of electrons, lowering conductivity. Conversely, annealing maximizes conductivity by creating a "clean" microstructure that is inherently softer and weaker.

Thermal vs. Electrical Conductivity

For most metals, electrical and thermal conductivity are tightly linked, as described by the Wiedemann-Franz Law. The electrons that carry electric charge are also primary carriers of thermal energy.

Therefore, a heat treatment that reduces electrical conductivity by scattering electrons will almost always reduce thermal conductivity as well.

Material-Specific Responses

The degree to which heat treatment affects conductivity is highly dependent on the specific alloy. The effect is dramatic in alloys designed for precipitation hardening (like 6000 or 7000 series aluminum) but is more subtle in plain carbon steels or pure metals.

Selecting the Right Treatment for Your Application

Your choice of heat treatment must be driven by the primary performance requirement of the component.

- If your primary focus is maximum electrical or thermal conductivity: Use a full annealing process. This is the standard for applications like busbars, high-frequency wiring, and heat exchanger fins.

- If your primary focus is maximum strength and hardness: Use precipitation hardening (for applicable alloys) or quenching and tempering, but you must design your system to tolerate the resulting lower conductivity. This is critical for structural components.

- If you need a balanced compromise: Use a carefully controlled tempering or aging process. By stopping the treatment at a specific point, you can achieve a target combination of strength and conductivity for components like springs, fasteners, or wear-resistant electrical contacts.

Ultimately, heat treatment empowers you to transform a single alloy into a material precisely engineered for its intended purpose.

Summary Table:

| Heat Treatment Process | Primary Effect on Microstructure | Typical Impact on Conductivity | Common Goal |

|---|---|---|---|

| Annealing | Increases grain size, reduces defects | Increases conductivity | Maximize electrical/thermal performance |

| Quenching | Creates fine grains, traps defects | Decreases conductivity | Maximize hardness and strength |

| Precipitation Hardening | Forms fine precipitates within grains | Significantly decreases conductivity | Achieve high strength in alloys |

Need to precisely engineer the conductivity and strength of your materials? The right lab equipment is crucial for developing and analyzing heat-treated samples. KINTEK specializes in high-quality lab furnaces, ovens, and consumables that provide the precise temperature control and uniform heating required for reliable heat treatment processes. Whether you are annealing for maximum conductivity or precipitation hardening for strength, our solutions help you achieve consistent, repeatable results. Let's discuss your laboratory's specific needs—contact our experts today to find the perfect equipment for your research and development.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost