Yes, in many cases, heat treatment is a fundamental process used to significantly increase the strength and hardness of a material, particularly in metals and alloys. However, it is not a one-size-fits-all process; different heat treatments can also be used to soften a material, improve its ductility, or relieve internal stresses. The outcome is entirely dependent on the specific material and the precise cycle of heating and cooling applied.

Heat treatment does not simply add strength; it fundamentally rearranges a material's internal microstructure. By controlling temperature and time, you are controlling the atomic arrangement to achieve a specific set of properties, often trading one attribute (like ductility) for another (like hardness).

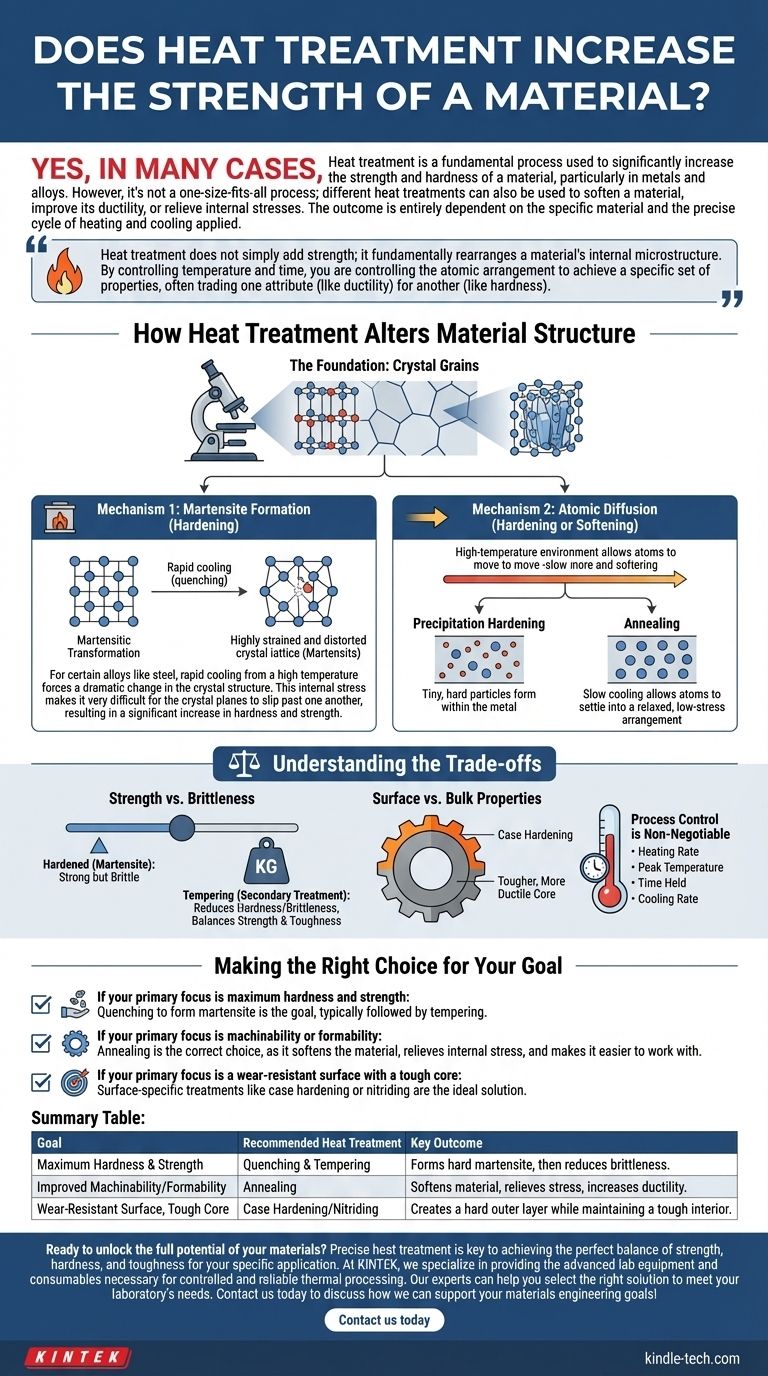

How Heat Treatment Alters Material Structure

Heat treatment works by exploiting the way atoms in a solid material, especially metals, respond to thermal energy. It allows for the controlled manipulation of the material's microscopic crystal structure, known as its microstructure.

The Foundation: Crystal Grains

Metals are crystalline, meaning their atoms are arranged in an orderly, repeating pattern called a lattice. These lattices group together to form microscopic crystals, or "grains." The size, shape, and internal structure of these grains dictate the material's bulk mechanical properties like strength, hardness, and ductility.

Mechanism 1: Martensite Formation (Hardening)

For certain alloys like steel, rapid cooling (quenching) from a high temperature forces a dramatic change in the crystal structure. This process is known as a martensitic transformation.

Atoms do not have time to move back to their normal, low-energy positions. They become trapped in a highly strained and distorted crystal lattice called martensite. This internal stress makes it very difficult for the crystal planes to slip past one another, resulting in a significant increase in hardness and strength.

Mechanism 2: Atomic Diffusion (Hardening or Softening)

When a material is held at a high temperature, atoms gain enough energy to move around, or diffuse, within the crystal lattice. This mechanism can be used for opposite effects.

In some alloys (like aluminum), it enables precipitation hardening, where tiny, hard particles form within the metal, obstructing movement and increasing strength.

Conversely, slow cooling allows atoms to settle into a relaxed, low-stress arrangement. This process, called annealing, relieves internal stresses, increases homogeneity, and typically makes the material softer and more ductile.

Understanding the Trade-offs

Increasing one property, like strength, almost always comes at the expense of another. This is the central challenge of materials engineering.

Strength vs. Brittleness

The most common trade-off is strength for toughness. A material hardened by creating martensite is exceptionally strong but also very brittle, meaning it is more likely to fracture or shatter under impact.

To counteract this, a secondary, lower-temperature heat treatment called tempering is often applied after quenching. Tempering reduces some of the hardness and brittleness, resulting in a more useful balance of high strength and adequate toughness.

Surface vs. Bulk Properties

Some applications require a hard, wear-resistant surface but a tougher, more ductile core that can absorb shock. Heat treatment can achieve this.

Processes like case hardening or the plasma treatments mentioned in research selectively modify only the surface chemistry and structure. They create a hard "case" without altering the bulk properties of the material underneath, providing the best of both worlds for components like gears and bearings.

Process Control is Non-Negotiable

The success of heat treatment hinges on precise control. The heating rate, the peak temperature, the time held at that temperature, and the cooling rate are all critical variables. A slight deviation can result in a part that is too soft, too brittle, cracked, or warped.

Making the Right Choice for Your Goal

The correct heat treatment is defined by your final objective for the material.

- If your primary focus is maximum hardness and strength: Quenching to form martensite is the goal, typically followed by tempering to reduce brittleness to an acceptable level.

- If your primary focus is machinability or formability: Annealing is the correct choice, as it softens the material, relieves internal stress, and makes it easier to work with.

- If your primary focus is a wear-resistant surface with a tough core: Surface-specific treatments like case hardening or nitriding are the ideal solution.

Ultimately, heat treatment empowers you to take a single material and precisely tailor its internal structure to meet a wide range of engineering demands.

Summary Table:

| Goal | Recommended Heat Treatment | Key Outcome |

|---|---|---|

| Maximum Hardness & Strength | Quenching & Tempering | Forms hard martensite, then reduces brittleness. |

| Improved Machinability/Formability | Annealing | Softens material, relieves stress, increases ductility. |

| Wear-Resistant Surface, Tough Core | Case Hardening/Nitriding | Creates a hard outer layer while maintaining a tough interior. |

Ready to unlock the full potential of your materials?

Precise heat treatment is key to achieving the perfect balance of strength, hardness, and toughness for your specific application. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for controlled and reliable thermal processing.

Our experts can help you select the right solution to meet your laboratory's needs. Contact us today to discuss how we can support your materials engineering goals!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout