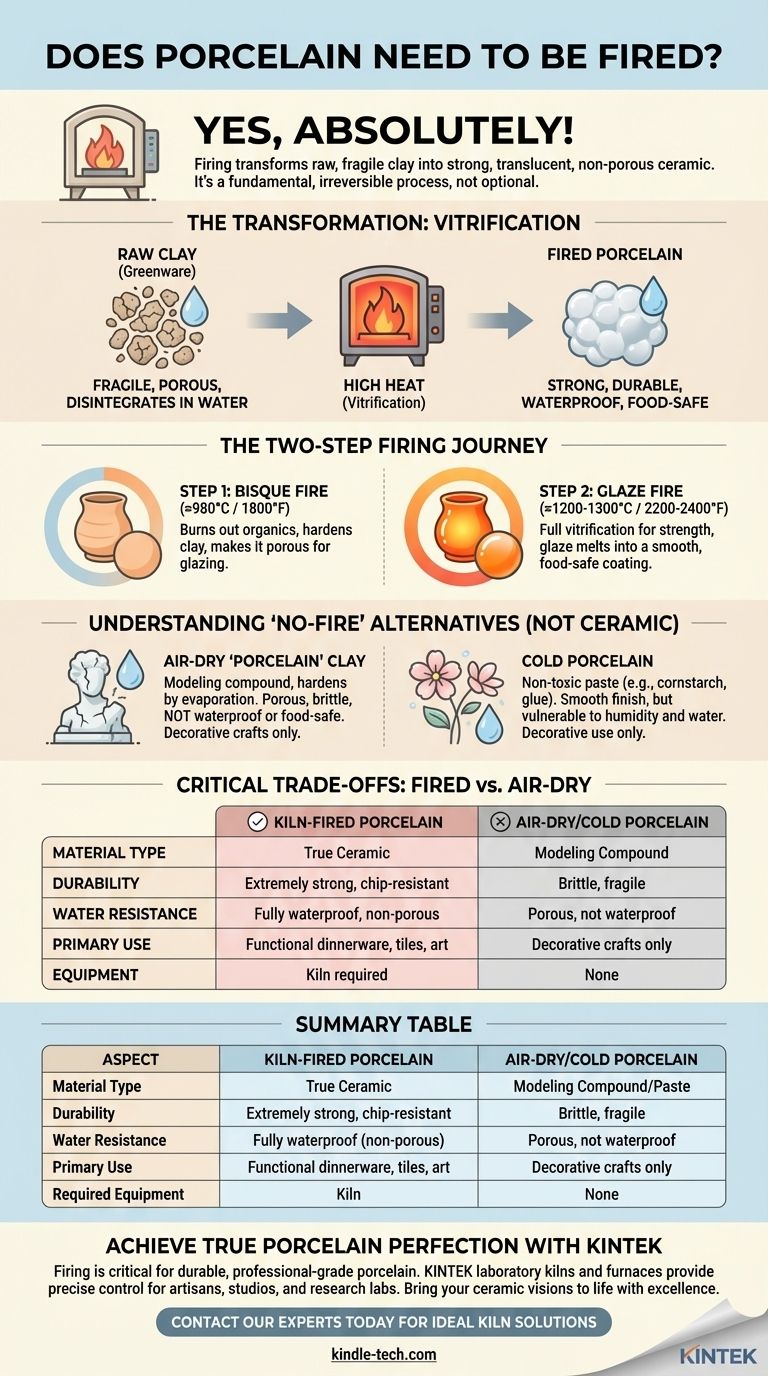

Yes, absolutely. Traditional porcelain must be fired in a kiln to transform it from fragile, raw clay into the strong, translucent, and non-porous material it is known for. Firing is not an optional step; it is the fundamental chemical and physical process that creates ceramic. Without it, the object remains merely dried clay, which will disintegrate if it comes into contact with water.

The core distinction to understand is between true, kiln-fired porcelain and materials marketed as "air-dry" or "cold" porcelain. While the latter are useful for certain crafts, they are entirely different substances that do not possess the durability, permanence, or water-resistance of authentic, fired porcelain.

What is Firing and Why is it Essential?

Firing is the process of heating clay to a very high temperature in a specialized oven called a kiln. This intense heat causes irreversible changes in the clay body, turning it into a permanent ceramic material.

The Transformation from Clay to Ceramic

The magic of firing is a process called vitrification. At high temperatures, the silica and other elements within the porcelain clay body melt and fuse together, forming a glass-like bond.

This process eliminates the pores between clay particles, making the final piece extremely dense.

Achieving Durability and Strength

Unfired porcelain, often called "greenware," is incredibly fragile. Firing is what gives porcelain its renowned hardness and strength, making it resistant to chipping, scratching, and daily wear. A fired piece can last for thousands of years.

Making it Waterproof

Vitrification makes porcelain non-porous, meaning it will not absorb water. This is why it's the material of choice for functional items like dinnerware, sinks, and tiles. An unfired piece would simply turn back into mud if you put water in it.

The Firing Process: A Two-Step Journey

True porcelain typically undergoes two separate firings to achieve its final state. Each firing has a distinct purpose.

The Bisque Fire (First Firing)

The first firing is called the bisque fire, which happens at a relatively lower temperature (around 1800°F / 980°C).

This initial firing burns out organic matter and hardens the clay, making it permanent and easier to handle for glazing. The resulting piece, called "bisqueware," is still porous enough to readily absorb the glaze.

The Glaze Fire (Second Firing)

After a liquid glaze is applied to the bisqueware, the piece goes back into the kiln for a glaze fire. This is a much higher-temperature firing, often reaching 2200-2400°F (1200-1300°C).

During this firing, the porcelain body fully vitrifies to achieve maximum strength, and the glaze melts into a smooth, glassy coating. This final layer makes the piece easy to clean and, if the glaze is formulated correctly, food-safe.

Understanding the "No-Fire" Alternatives

Confusion often arises from products that use the name "porcelain" but do not require a kiln. It's critical to know these are not ceramic materials.

Air-Dry "Porcelain" Clay

This is a modeling compound that hardens through the evaporation of water. It's convenient and accessible for decorative crafts.

However, it is not true porcelain. It remains porous, is far more brittle, and is not waterproof or food-safe. It cannot be placed in a kiln.

Cold Porcelain

Cold porcelain is a non-toxic paste, often homemade from cornstarch and white glue. It air-dries to a smooth, slightly translucent finish, making it popular for crafting delicate flowers and figurines.

Like air-dry clay, it is not a ceramic. It is vulnerable to humidity and will be destroyed by water. It is for decorative use only.

The Critical Trade-offs: Fired vs. Air-Dry

Choosing between these materials means understanding a clear set of trade-offs in performance and accessibility.

Durability and Functionality

Only kiln-fired porcelain is durable enough for functional use. It is waterproof, heat-resistant, and food-safe when properly glazed. Air-dry materials are strictly for decorative objects that will not be handled often or exposed to moisture.

Equipment and Accessibility

The biggest barrier to working with true porcelain is the need for a kiln. These are expensive and require a dedicated space. Air-dry and cold porcelain are highly accessible, requiring no special equipment, making them ideal for home crafters and hobbyists.

The Final Finish

True porcelain has a unique, luminous translucency and strength that cannot be replicated with air-dry materials. The process of firing and glazing creates a finish that is both beautiful and exceptionally resilient.

Making the Right Choice for Your Project

To select the correct material, you must first define your goal.

- If your primary focus is creating durable, functional items (like dinnerware, mugs, or tiles): You must use traditional porcelain clay that will be fired in a kiln.

- If your primary focus is decorative sculpture or crafts without access to a kiln: Air-dry "porcelain" or cold porcelain are excellent, accessible alternatives.

- If your primary focus is achieving the unique translucency and strength of true porcelain: Firing is the only process that will create the genuine article.

Ultimately, the material you choose determines the fundamental nature and purpose of your finished piece.

Summary Table:

| Aspect | Kiln-Fired Porcelain | Air-Dry/Cold Porcelain |

|---|---|---|

| Material Type | True Ceramic | Modeling Compound/Paste |

| Durability | Extremely strong, chip-resistant | Brittle, fragile |

| Water Resistance | Fully waterproof (non-porous) | Porous, not waterproof |

| Primary Use | Functional dinnerware, tiles, art | Decorative crafts only |

| Required Equipment | Kiln | None |

Ready to create durable, professional-grade porcelain?

Firing is the critical step that transforms fragile clay into a permanent, functional masterpiece. To achieve the true strength, translucency, and waterproof quality of authentic porcelain, you need the right equipment.

KINTEK specializes in high-performance laboratory kilns and furnaces, trusted by artisans, studios, and research labs for precise temperature control and reliable results. Whether you're producing fine china, technical ceramics, or artistic pieces, our solutions are engineered for excellence.

Let us help you bring your ceramic visions to life with equipment built for perfection.

Contact our experts today to find the ideal kiln for your porcelain projects!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products