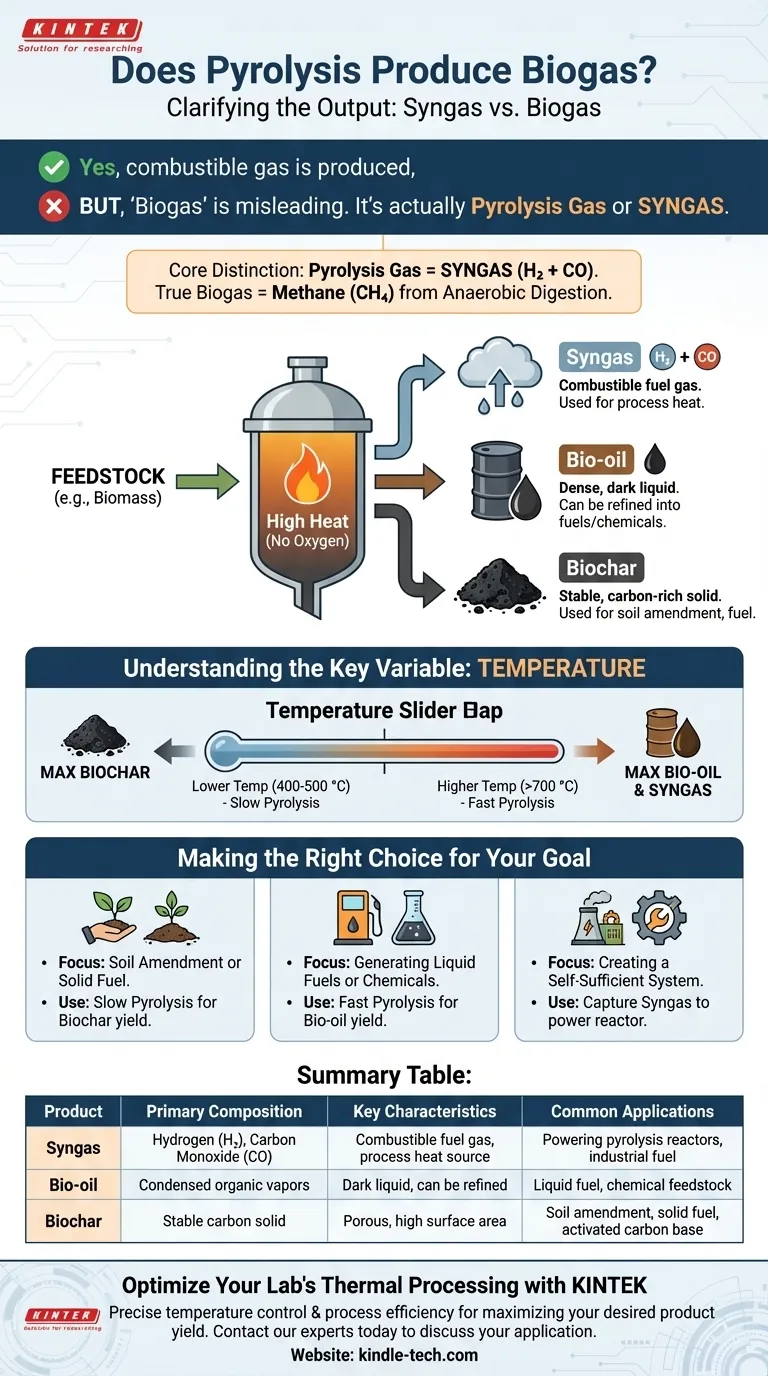

Yes, pyrolysis produces a combustible gas, but the term "biogas" can be misleading and is often used incorrectly in this context. While some sources use the term, the gas produced is fundamentally different in composition and is more accurately identified as pyrolysis gas or syngas.

The core distinction is this: The gas from pyrolysis is syngas—a mix of hydrogen and carbon monoxide—while true biogas is primarily methane produced by anaerobic digestion. Understanding this difference is critical to understanding the process and its outputs.

What Gas Does Pyrolysis Actually Produce?

Pyrolysis is a thermochemical decomposition process, meaning it uses high heat in the absence of oxygen to break down materials. This process creates a specific type of fuel gas with its own unique properties and applications.

Defining Pyrolysis Gas (Syngas)

The non-condensable gas that results from pyrolysis is a mixture of combustible and non-combustible components.

Its primary constituents are hydrogen (H₂) and carbon monoxide (CO). It also contains smaller amounts of methane (CH₄) and carbon dioxide (CO₂). This specific mixture is technically known as synthesis gas, or syngas.

Why the Name Matters: Biogas vs. Syngas

Clarity in terminology is essential. "Biogas" is the common name for the gas produced by the biological breakdown of organic matter by microbes in an oxygen-free environment (anaerobic digestion).

Biogas is composed mostly of methane (CH₄), the primary component of natural gas. Syngas, with its high concentration of hydrogen and carbon monoxide, has different combustion properties and industrial uses.

The Role of the Feedstock

The exact composition of the syngas depends heavily on the material being processed, known as the feedstock.

Pyrolyzing biomass like wood or agricultural waste will produce the typical H₂ and CO mixture. However, pyrolyzing other materials, like methane, produces primarily solid carbon and gaseous hydrogen, with no carbon monoxide.

The Three Core Products of Pyrolysis

Syngas is just one of three distinct outputs from the pyrolysis process. The ratio of these products can be controlled by adjusting the process conditions to meet specific goals.

The Solid Product: Biochar

Biochar (or coke) is the stable, carbon-rich solid that remains after the volatile components have been driven off.

This material can be used as a solid fuel, an agricultural soil conditioner to improve water retention, or as a base for activated carbon.

The Liquid Product: Bio-oil

Bio-oil (or pyrolysis oil) is a dense, dark liquid produced when the hot vapors from the process are rapidly cooled and condensed.

This oil can be burned to generate heat and electricity, or it can be further refined into transportation fuels and specialty chemicals.

The Gaseous Product: Syngas

As discussed, syngas is the non-condensable gas fraction. Its most common use is to be cycled back into the pyrolysis plant.

By burning the syngas it produces, the facility can generate the heat required to sustain the pyrolysis reaction, significantly improving its overall energy efficiency.

Understanding the Key Variable: Temperature

The most critical factor determining the ratio of solid, liquid, and gas products is temperature. By controlling the heat, operators can favor the creation of one product over the others.

Lower Temperatures for Solid Output

Operating at relatively low temperatures, typically around 400–500 °C, maximizes the production of biochar. This is often referred to as "slow pyrolysis."

Higher Temperatures for Fuel Output

Conversely, higher temperatures above 700 °C favor the production of liquids (bio-oil) and gases (syngas). This "fast pyrolysis" is used when the primary goal is to generate fuel.

Making the Right Choice for Your Goal

The pyrolysis process can be fine-tuned to achieve different objectives based on the desired end product.

- If your primary focus is soil amendment or solid fuel: Use a lower-temperature "slow pyrolysis" process to maximize the yield of biochar.

- If your primary focus is generating liquid fuels or chemicals: Use a higher-temperature "fast pyrolysis" process to maximize the yield of bio-oil.

- If your primary focus is creating a self-sufficient system: Capture the syngas and use it as the fuel source to power the pyrolysis reactor itself.

By understanding that pyrolysis produces syngas, bio-oil, and biochar, you can effectively control the process to create the specific high-value products you need.

Summary Table:

| Product | Primary Composition | Key Characteristics | Common Applications |

|---|---|---|---|

| Syngas | Hydrogen (H₂), Carbon Monoxide (CO) | Combustible fuel gas, process heat source | Powering pyrolysis reactors, industrial fuel |

| Bio-oil | Condensed organic vapors | Dark liquid, can be refined | Liquid fuel, chemical feedstock |

| Biochar | Stable carbon solid | Porous, high surface area | Soil amendment, solid fuel, activated carbon base |

Optimize Your Lab's Thermal Processing with KINTEK

Understanding the precise outputs of pyrolysis—syngas, bio-oil, and biochar—is essential for achieving your research or production goals. Whether you are focusing on energy recovery, material synthesis, or waste valorization, the right equipment is key to controlling product yields and quality.

KINTEK specializes in high-quality lab pyrolysis systems and reactors designed for precise temperature control and process efficiency. Our equipment helps researchers and lab professionals like you maximize the yield of your desired product—be it syngas for energy, bio-oil for fuels, or biochar for materials.

Let us help you tailor your pyrolysis process for superior results.

Contact our experts today to discuss your specific application and discover how KINTEK's reliable lab equipment can enhance your thermal conversion projects.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- Why must a tube furnace with vacuum or inert protection be used for CTMSS? Key to Hydrothermal Stability

- What is the function of the ceramic tube in a DBD plasma jet? Enhancing Stability for Delicate Material Treatment

- What role do high-temperature sintering or tube furnaces play in biomass catalysts? Engineering the Carbon Skeleton

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- Why is a tube furnace required for Se/PPS mercury removal? Optimize Thermal Control for Flue Gas Research

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- What role does a horizontal tube furnace play in TiB2 synthesis? Optimize High-Quality Nanopowder Production