Yes, temperature is arguably the single most critical factor affecting hydraulic fluid's performance and lifespan. Both high and low temperatures dramatically alter the fluid's physical and chemical properties, directly impacting the health and efficiency of your entire hydraulic system. Understanding these effects is not just a technical detail; it is fundamental to system reliability.

The core issue is that temperature directly controls the fluid's viscosity (its thickness). When the fluid is too hot, it becomes too thin, leading to wear and inefficiency. When it is too cold, it becomes too thick, causing sluggish performance and potential startup damage.

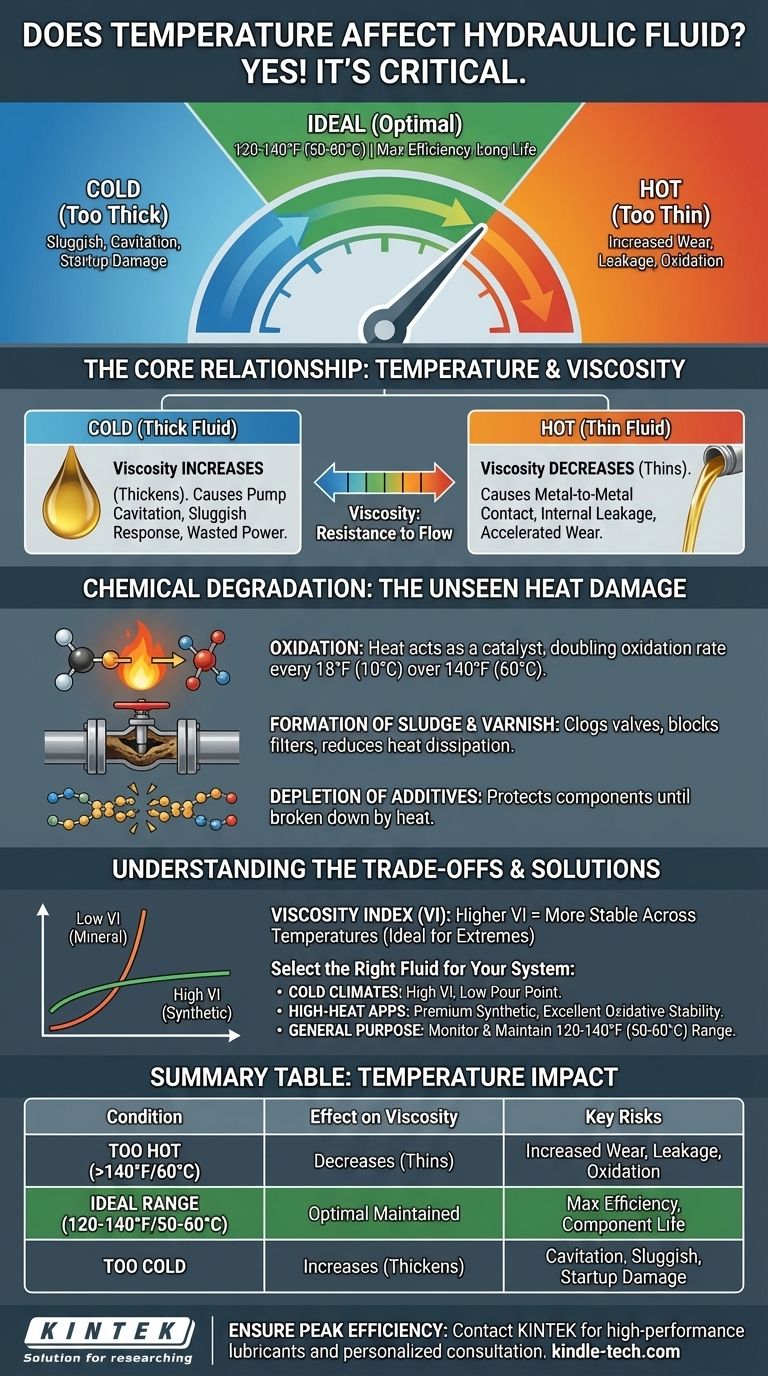

The Core Relationship: Temperature and Viscosity

The primary job of hydraulic fluid is to transmit power, but it must do so while lubricating moving parts. This dual role is entirely dependent on maintaining the correct viscosity.

What is Viscosity?

Think of viscosity as the fluid's resistance to flow. Honey has a high viscosity, while water has a low viscosity. Hydraulic systems are designed to operate with a fluid within a very specific viscosity range.

How Heat Thins the Fluid (Low Viscosity)

As hydraulic fluid heats up, its viscosity drops, meaning it becomes thinner. This leads to several critical problems.

The fluid film that separates moving components becomes too thin to provide adequate lubrication, causing metal-to-metal contact and accelerating wear on pumps, motors, and valves.

Thinner fluid also increases internal leakage past seals and clearances, which reduces system efficiency. The actuators may move slower, and more energy is wasted as heat, creating a vicious cycle of rising temperatures.

How Cold Thickens the Fluid (High Viscosity)

When the fluid is cold, its viscosity increases, meaning it becomes thicker. This is especially problematic during system startup.

Thick fluid flows poorly, which can starve the pump of oil. This condition, known as cavitation, is destructive to the pump and is a leading cause of premature failure.

The increased resistance also demands more energy to push the fluid through the system, leading to sluggish actuator response and wasted power until the system reaches its operating temperature.

Chemical Degradation: The Unseen Damage from Heat

Beyond the immediate physical changes, high temperatures trigger destructive chemical reactions within the fluid, permanently degrading it.

The Process of Oxidation

Heat acts as a catalyst, dramatically accelerating the rate at which the fluid reacts with oxygen—a process called oxidation. For every 18°F (10°C) increase above 140°F (60°C), the oxidation rate roughly doubles, effectively cutting the fluid's service life in half.

The Formation of Sludge and Varnish

Oxidation creates byproducts like sludge and varnish. These contaminants are insoluble and will coat internal surfaces, clog tight-tolerance valves, block filters, and reduce the system's ability to dissipate heat.

Depletion of Critical Additives

Hydraulic fluids contain a sophisticated package of additives, including anti-wear agents, rust inhibitors, and viscosity index improvers. High heat breaks down and depletes these additives, leaving the system's components unprotected.

Understanding the Trade-offs

Not all hydraulic fluids respond to temperature changes in the same way. The key is to match the fluid's properties to the system's operating environment.

The Role of the Viscosity Index (VI)

The Viscosity Index (VI) is a number that indicates how much a fluid's viscosity changes with temperature. A fluid with a high VI changes less, remaining more stable across a wide temperature range. This is highly desirable for mobile equipment or systems that operate in extreme climates.

Mineral vs. Synthetic Fluids

Standard mineral-based fluids are effective and economical for systems that operate within a stable, controlled temperature range.

Synthetic fluids generally have a much higher VI and superior thermal stability. They resist oxidation far better at high temperatures, making them the correct choice for demanding applications, despite their higher initial cost.

The Importance of the Operating Window

Every hydraulic system has an ideal operating temperature window, typically between 120-140°F (50-60°C). Operating consistently above or below this range will compromise performance and reduce component life. The goal is to use coolers, heaters, and proper fluid selection to stay within this target zone.

How to Apply This to Your System

Managing fluid temperature is a proactive measure that directly translates to increased reliability and lower operating costs. Your choice of fluid and system hardware should be dictated by the expected operating conditions.

- If your primary focus is reliability in cold climates: Choose a fluid with a high viscosity index and a low pour point to ensure smooth, safe startups.

- If your primary focus is performance in high-heat applications: Select a premium synthetic fluid with excellent oxidative stability and ensure your system has adequate cooling capacity.

- If your primary focus is general-purpose, stable operation: Monitor fluid temperature and keep it within the recommended 120-140°F (50-60°C) range to maximize both fluid and component lifespan.

Proactively managing fluid temperature is the single most effective strategy for ensuring the long-term health and efficiency of any hydraulic system.

Summary Table:

| Temperature Condition | Effect on Fluid Viscosity | Key Risks to Your System |

|---|---|---|

| Too Hot (>140°F / 60°C) | Viscosity decreases (thins) | Increased wear, internal leakage, fluid oxidation |

| Ideal Range (120-140°F / 50-60°C) | Optimal viscosity maintained | Maximum system efficiency and component lifespan |

| Too Cold | Viscosity increases (thickens) | Pump cavitation, sluggish response, startup damage |

Ensure your hydraulic systems operate at peak efficiency and reliability. The right fluid and thermal management strategy are critical to preventing downtime and costly repairs. KINTEK specializes in high-performance lubricants and fluids designed for extreme temperatures and demanding applications.

Our experts can help you select the ideal fluid to protect your equipment.

Contact our technical team today for a personalized consultation to extend the life of your hydraulic systems.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Which mechanism is used in a press machine? Harnessing Hydraulic Power for Maximum Force

- What is the purpose of using laboratory hydraulic presses for molecular sieve catalysts? Optimize Reactor Performance

- What is a hydraulic jack? The Simple Physics of Lifting Heavy Loads

- Why use laboratory hydraulic presses for diamond/copper powders? Achieve Superior Green Compact Density

- What is the difference between a hydraulic and mechanical shaping machine? Choose the Right Machine for Your Shop

- What is qualitative analysis in XRF? Identify Elemental Composition with Precision

- Why is a hydraulic press required for all-solid-state batteries? Achieve Precision Layer Molding up to 200 MPa

- Why Use a Laboratory Hydraulic Press for LLZTO Ceramic Electrolytes? Achieving High-Density Green Pellets