To avoid overloading an electrolytic cell, you must operate strictly within the rated current and voltage specified for both the cell and its power supply. Exceeding these limits is the primary cause of overloading, which risks catastrophic equipment failure, electric shock, chemical burns, and even fire or explosion.

The core principle of safe electrolysis is treating the cell and power supply as an integrated system. Overloading isn't just an operational misstep; it's a fundamental safety failure that occurs when you demand more electrical power than any component in that system can safely handle.

The Core Principle: Respecting Electrical Limits

An electrolytic cell is designed to function within a specific electrical window. Pushing beyond this window introduces instability and significant danger.

What is Overloading?

Overloading happens when you force more electrical current (amperage) or apply a higher electrical potential (voltage) than the cell's components can manage.

This excess energy doesn't simply create a more efficient reaction. It is converted into destructive heat and can trigger unintended, hazardous side reactions.

The Critical Role of Ratings

Every electrolytic cell and power supply has maximum ratings provided by the manufacturer. These are not suggestions; they are absolute safety limits.

Never assume the limits. Always verify the specifications for your specific equipment before operation.

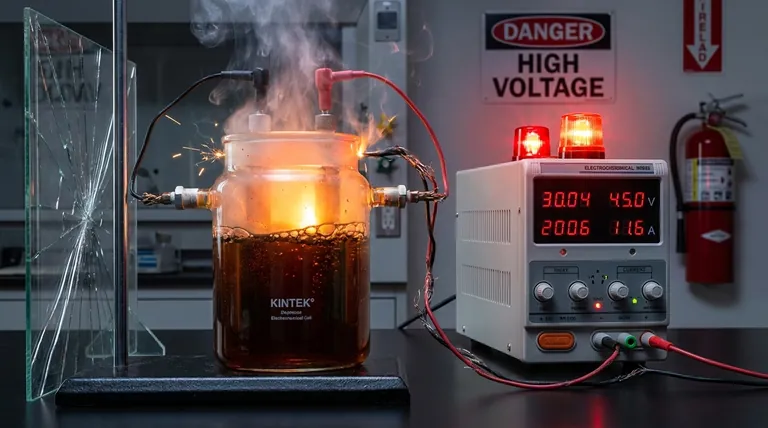

The Primary Risks of an Overloaded Cell

The consequences of overloading range from damaged equipment to severe personal injury. Understanding these risks is crucial for prevention.

Equipment Damage and Failure

The most immediate effect of excess current is intense heat. This can melt electrodes, crack the cell container, and permanently damage the power supply.

Electrical Shock

An overloaded and failing system can create short circuits or expose live electrical contacts. Direct contact with electrodes or the electrolyte can cause severe or fatal electric shock.

Chemical Hazards

Overheating can cause the electrolyte to boil and splash, leading to serious chemical burns. Some reactions can also release toxic gases when pushed beyond their intended parameters.

Fire and Explosion Hazards

Many electrolytic processes, especially the electrolysis of water, produce highly flammable hydrogen gas.

An overloaded circuit can easily create a spark, which can ignite accumulated gases and cause a fire or violent explosion. For this reason, you must never have open flames or other ignition sources near an active cell.

Common Pitfalls to Avoid

Most overloading incidents stem from a few common, preventable mistakes. Awareness is the first step in maintaining a safe environment.

Mismatched Components

A common error is pairing a powerful supply with a low-rated cell. The power supply can easily deliver more current than the cell can handle, leading to immediate overload.

Ignoring Environmental Controls

Proper ventilation is non-negotiable. Without it, flammable or toxic gases can accumulate to dangerous concentrations.

Procedural Complacency

Always de-energize the power supply before making adjustments or touching electrodes. Familiarity can lead to forgetting basic safety steps, which is often when accidents occur.

A Checklist for Safe Operation

Use these guidelines to ensure both safety and successful outcomes for your work.

- If your primary focus is safety: Always verify and respect the voltage and current ratings of both the cell and the power supply before every single operation.

- If your primary focus is equipment longevity: Operate your system at 80-90% of its maximum rated current to reduce thermal stress and significantly extend its lifespan.

- If you are in a shared or educational environment: Ensure all components are clearly labeled with their electrical limits and establish strict protocols, including an absolute prohibition of open flames.

Ultimately, understanding and respecting the operational limits of your equipment is the foundation of safe and effective electrolysis.

Summary Table:

| Action to Avoid Overload | Primary Risk if Overloaded |

|---|---|

| Operate within rated current/voltage | Catastrophic equipment failure |

| Use properly matched components | Severe electric shock hazard |

| Ensure adequate ventilation | Chemical burns from boiling electrolyte |

| De-energize before adjustments | Fire or explosion from ignited gases |

Ensure your lab's electrolysis processes are safe and efficient with the right equipment from KINTEK.

Overloading an electrolytic cell is a critical safety failure that risks both personnel and experiments. KINTEK specializes in providing reliable lab equipment and consumables, including power supplies and cells designed to work together safely. Our products help you maintain precise control, prevent hazardous overloads, and achieve consistent, repeatable results.

Don't compromise on safety. Let our experts help you select the ideal system for your specific laboratory needs.

Contact KINTEK today to discuss your requirements and ensure a safer lab environment.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup