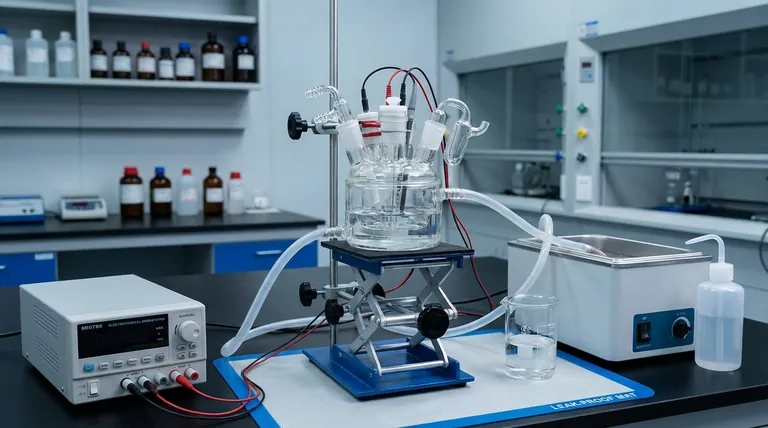

To properly connect an electrolytic cell, you must first physically secure it and establish any necessary environmental controls, like a water bath. The critical step is connecting the electrode leads to the corresponding terminals on the power supply or electrochemical workstation, paying strict attention to matching the positive and negative polarity to avoid damaging the cell or invalidating your results.

The success of an electrolytic experiment hinges not just on plugging in wires, but on a systematic process that prioritizes correct electrical polarity, stable environmental conditions, and rigorous safety checks before any power is applied.

Foundational Setup: Positioning and Environment

Before making any electrical connections, the physical and chemical environment of the cell must be correctly established. This foundation ensures stability, safety, and experimental accuracy.

Securing the Cell

Position the electrolytic cell on the base of a stand and tighten the fixing knobs. This ensures the cell remains vertical and stable throughout the experiment.

If you are working with corrosive electrolytes, always place a leak-proof pad underneath the cell as a crucial safety precaution.

Establishing Temperature Control

For experiments sensitive to temperature, place the cell into a constant temperature water bath.

Connect the water bath's inlet and outlet pipes to the cell's jacket to ensure proper circulation and maintain a stable internal temperature.

Preparing the Electrolyte

Prepare the electrolyte solution according to your experimental protocol, using high-purity chemical reagents and deionized or distilled water to prevent contamination.

If your experiment requires a specific atmosphere, such as nitrogen, purge the cell with the gas to remove air before adding the electrolyte.

The Critical Electrical Connections

With the physical setup complete, the focus shifts to the electrical connections. This stage requires precision and careful verification to protect your equipment and ensure valid data.

Verifying Power Source Specifications

Before you connect anything, confirm that the voltage and current capabilities of your power supply are within the specifications required by your electrolytic cell and electrodes.

Connecting the Electrodes

First, install the three electrodes (working, counter, and reference) correctly in the reaction vessel, ensuring appropriate spacing between them.

Connect the electrode wires to the corresponding ports on your electrochemical workstation. Correct polarity is non-negotiable; reversing the positive and negative terminals can lead to experimental failure or cell damage.

Adding the Electrolyte

Pour the prepared electrolyte into the cell. The level should be high enough to fully submerge the electrode surfaces but low enough to avoid immersing the electrode rods and connection points.

Common Pitfalls and Safety Protocols

A successful experiment is a safe one. Adhering to safety protocols and being aware of common mistakes is essential for protecting both yourself and your equipment.

The Risk of Reversed Polarity

The single most common electrical error is reversing the positive and negative terminals. Always double-check these connections before turning on the power source.

Pre-Experiment Equipment Checks

Before every experiment, perform a visual inspection of all power cords and connection lines. Ensure they are intact and free of damage to prevent electrical safety hazards.

Personal Safety During Operation

Avoid direct physical contact with the electrodes and the electrolyte during the experiment to prevent the risk of electric shock or chemical burns.

Furthermore, keep open flames and other flammable materials far away from the electrolytic cell to mitigate fire or explosion hazards, especially if gases like hydrogen are being produced.

Monitoring the Experiment

Once running, closely monitor the working state of the cell. Watch for key indicators like bubble formation on the electrodes, color changes in the solution, or temperature fluctuations, as these signal the progress of your reaction.

Checklist for a Successful Experiment

Use these points to guide your setup based on your primary objective.

- If your primary focus is experimental accuracy: Prioritize high-purity reagents, precise temperature control via a water bath, and correct electrolyte levels.

- If your primary focus is equipment safety: Double-check that your power source specifications match the cell's requirements and verify all electrical connections, especially polarity, are correct before activation.

- If your primary focus is personal safety: Always use leak-proof pads for corrosive materials, inspect all wiring for damage, and avoid direct contact with energized components.

A methodical and safety-conscious setup is the foundation of every reliable electrochemical experiment.

Summary Table:

| Step | Key Action | Purpose/Critical Check |

|---|---|---|

| 1. Foundation | Secure cell on stand; use leak-proof pad. | Ensure stability and safety from spills. |

| 2. Temperature Control | Connect water bath to cell jacket. | Maintain a constant reaction temperature. |

| 3. Electrolyte Prep | Use high-purity reagents; purge with gas if needed. | Prevent contamination and control atmosphere. |

| 4. Electrical Connection | Connect electrode leads to correct terminals on power supply/ workstation. | VERIFY POLARITY to avoid damage. |

| 5. Safety Check | Inspect all cords and wiring; avoid contact with components. | Prevent electric shock and ensure safe operation. |

Achieve Flawless Electrochemical Experiments with KINTEK

Setting up your electrolytic cell correctly is critical for the safety and accuracy of your research. KINTEK specializes in providing high-quality lab equipment and consumables tailored to your laboratory's electrochemical needs. From reliable electrochemical workstations to durable cells and high-purity reagents, our products are designed to support precise and safe experiments.

Let our experts help you build a more efficient and safer lab. Contact us today to find the perfect solutions for your specific application and ensure your experimental success.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments