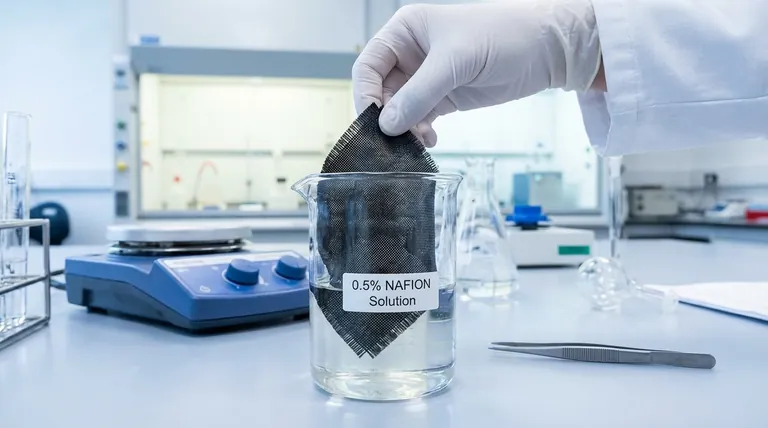

To maintain the flexibility of carbon cloth, the most direct method is to periodically soak it in a 0.5% NAFION solution. This treatment acts as a reinforcing agent for the fiber matrix, helping to preserve its mechanical integrity against bending and stress over time.

The core challenge is that treatments designed to improve one property of carbon cloth, like its chemical reactivity, can often degrade another, like its mechanical flexibility. The key is to select a treatment that reinforces the cloth's structure without making it brittle.

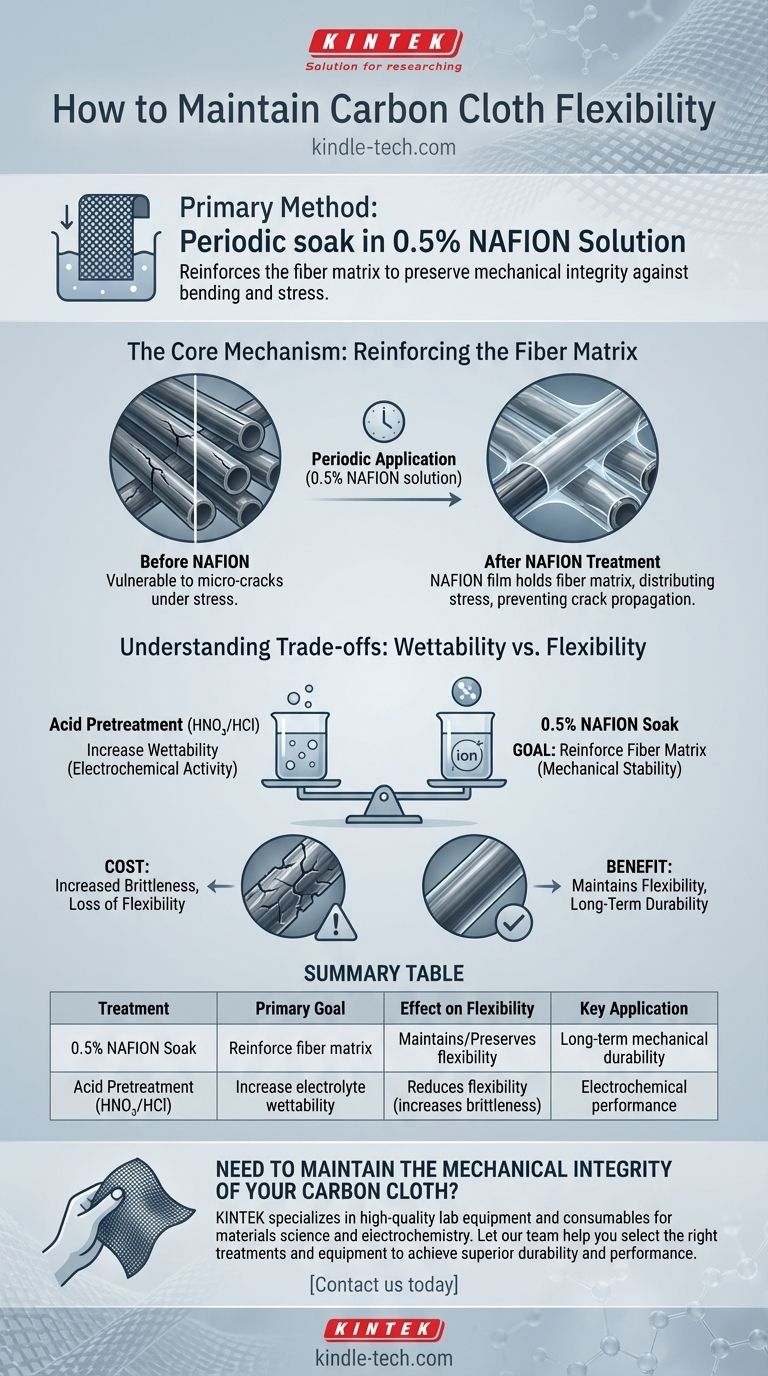

The Core Mechanism: Reinforcing the Fiber Matrix

Maintaining flexibility in carbon cloth isn't about making individual carbon fibers more pliable. It's about preserving the integrity of the woven structure and preventing the fibers from cracking or breaking apart under stress.

What is Carbon Cloth?

Carbon cloth is a fabric woven from thousands of microscopic carbon fibers. Its flexibility comes from the ability of these fibers to move and bend together as a collective unit.

When the cloth is stressed, individual fibers can fracture. Over time, this accumulated micro-damage leads to brittleness and a loss of overall flexibility.

NAFION as a Structural Reinforcer

NAFION is an ionomer, a specialized polymer that can act as a binder. When carbon cloth is soaked in a dilute NAFION solution, the polymer coats the carbon fibers.

This coating creates a thin, flexible film that holds the fiber matrix together. It helps distribute stress more evenly across the fabric and prevents the propagation of micro-cracks, thereby preserving the cloth's ability to bend without failing.

The Application Process

The process is straightforward: the carbon cloth is submerged in a 0.5% NAFION solution for a designated period. This allows the solution to penetrate the porous structure and coat the individual fibers before the solvent is evaporated.

This process should be performed periodically as needed, depending on the mechanical stress the material undergoes in its specific application.

Understanding the Trade-offs: Wettability vs. Flexibility

In many electrochemical applications, treatments are used to enhance performance. However, these can have unintended consequences for the material's mechanical properties.

The Goal of Acid Pretreatment

A common procedure is to pre-treat carbon cloth with strong acids like nitric acid (HNO₃) or hydrochloric acid (HCL) at elevated temperatures.

The purpose of this treatment is to increase electrolyte wettability. The acid creates functional groups on the carbon fiber surface, making it more hydrophilic and improving its interface with liquid electrolytes.

The Hidden Cost: Increased Brittleness

This chemical enhancement comes at a mechanical cost. The same acid treatment that improves wettability can also oxidize and etch the carbon fibers.

This etching creates surface defects that act as stress concentration points. As a result, acid-treated carbon cloth often becomes significantly more brittle and loses its flexibility, directly opposing the user's goal.

Choosing the Right Treatment

Therefore, a critical distinction must be made between treatments for mechanical stability (NAFION) and those for electrochemical activity (acid). Applying the wrong one can compromise your device or experiment.

Making the Right Choice for Your Goal

Your choice of treatment depends entirely on the primary performance requirement for your carbon cloth.

- If your primary focus is mechanical flexibility and long-term durability: Use a periodic 0.5% NAFION solution soak to reinforce the fiber structure.

- If your primary focus is enhancing electrolyte wettability for an electrochemical application: Use a controlled acid pretreatment, but accept that this will likely reduce the material's flexibility and lifespan.

Understanding the purpose behind each treatment is the key to preserving the properties you need most.

Summary Table:

| Treatment | Primary Goal | Effect on Flexibility | Key Application |

|---|---|---|---|

| 0.5% NAFION Soak | Reinforce fiber matrix | Maintains/Preserves flexibility | Long-term mechanical durability |

| Acid Pretreatment (HNO₃/HCl) | Increase electrolyte wettability | Reduces flexibility (increases brittleness) | Electrochemical performance |

Need to maintain the mechanical integrity of your carbon cloth?

KINTEK specializes in high-quality lab equipment and consumables for materials science and electrochemistry. Whether you're working with carbon cloth for electrodes, filtration, or composite materials, we provide the tools and expertise to ensure your materials perform reliably over time.

Let our team help you select the right treatments and equipment to achieve superior durability and performance in your lab.

Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Special Heat Press Mold for Lab Use

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

- Ring Press Mold for Lab Applications

People Also Ask

- How can the lifespan of carbon paper be extended? Reinforce Edges with Epoxy for Maximum Durability

- What are the key properties of carbon felt? Unlocking High-Temperature & Electrochemical Performance

- How is carbon paper constructed? The Engineered Porous Scaffold for High-Performance Applications

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What role does hydrophilic carbon fiber paper play as an electrode material? Enhancing Flow Cell Efficiency