To significantly extend the lifespan of carbon paper, the most effective method is to coat its edges with a diluted epoxy resin. This simple treatment reinforces the material's most vulnerable points, drastically improving its durability and resistance to cracking during handling and use.

The primary weakness of carbon paper is not the material itself, but its mechanical fragility, especially at the edges. The key to extending its life is not just careful handling, but strategically reinforcing these vulnerable areas to prevent the initiation and spread of cracks.

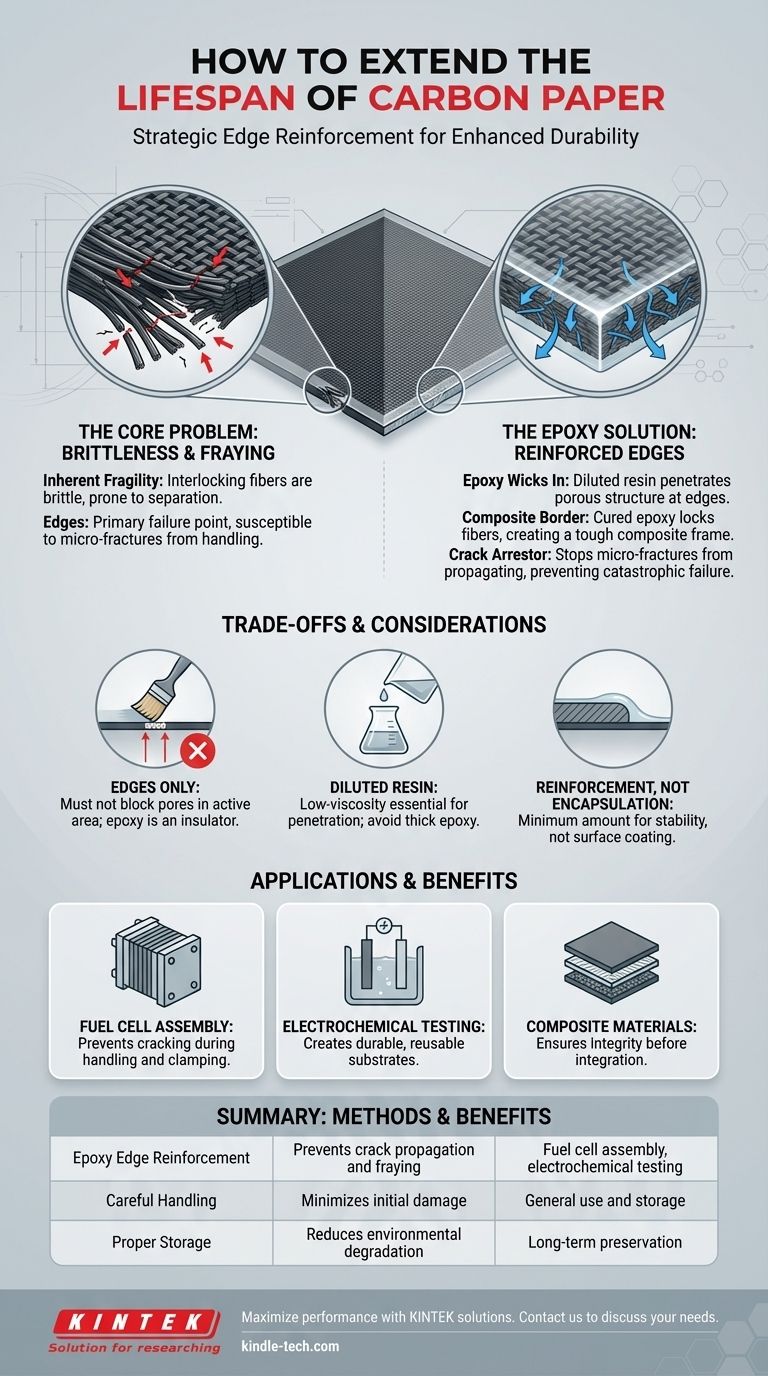

The Core Problem: Why Carbon Paper Fails

Carbon paper is a high-performance material used in demanding applications like fuel cells and electrochemical testing. However, its structure of interlocking carbon fibers makes it inherently brittle and susceptible to mechanical failure.

Brittleness and Fraying

The material's strength comes from its carbon fiber network, but this same structure is prone to fraying. Individual fibers can easily separate, particularly when subjected to stress from cutting, clamping, or repeated handling.

The Vulnerability of Edges

The edges are the primary failure point. Any cut or shear action introduces micro-fractures and stress concentrations. These almost invisible defects act as starting points for larger cracks that can propagate across the entire sheet, rendering it useless.

Impact in High-Tech Applications

In applications like Gas Diffusion Layers (GDLs) for fuel cells, a crack can compromise gas flow and electrical pathways. For electrochemical substrates, a frayed edge can lead to inconsistent results and short-circuiting.

The Epoxy Reinforcement Solution Explained

Applying a diluted epoxy resin to the edges directly counteracts the material's inherent mechanical weaknesses. It transforms a fragile edge into a robust, reinforced border.

How Epoxy Works

A low-viscosity, diluted epoxy wicks into the porous fiber structure at the very edge of the paper. It penetrates a short distance, saturating the network of carbon fibers in that localized area.

Creating a Reinforced Composite Edge

Once cured, the epoxy acts as a strong binding agent. It locks the carbon fibers in place, creating a solid, miniature composite frame around the perimeter of the carbon paper.

Preventing Crack Propagation

This reinforced edge serves as a "crack arrestor." Even if a new micro-fracture forms from handling, its ability to spread is stopped cold by the tough, epoxy-infused border. This prevents small nicks from becoming catastrophic failures.

Understanding the Trade-offs and Considerations

While effective, this technique requires precision. The goal is to reinforce the material without compromising its critical function in the active area.

Apply to Edges Only

The epoxy treatment must be meticulously confined to the edges. Epoxy is an electrical insulator and will block the pores essential for fluid or gas transport. Any contamination of the central, active area will ruin the component's performance.

Use a Diluted, Low-Viscosity Resin

A thick, undiluted epoxy will simply sit on the surface. For effective reinforcement, the resin must be thin enough to penetrate the fiber network, which typically requires dilution with an appropriate solvent.

The Goal is Reinforcement, Not Encapsulation

You are not trying to coat the paper; you are trying to infuse its edges. The goal is to add mechanical stability with the absolute minimum amount of resin required to prevent fraying and crack propagation.

Making the Right Choice for Your Goal

Properly treating carbon paper transforms it from a fragile but necessary component into a durable and reliable one. The key is applying this technique with your specific application in mind.

- If your primary focus is fuel cell assembly: Reinforce the edges with diluted epoxy to prevent cracking and delamination during the handling and clamping process.

- If your primary focus is electrochemical testing: Apply the edge treatment to create durable, reusable substrates that can withstand repeated use without fraying or failing.

- If your primary focus is creating composite materials: Use edge reinforcement to ensure the integrity of the carbon paper layer before it is integrated into the larger composite structure.

Strategic reinforcement is the key to unlocking the full durability and performance potential of this versatile material.

Summary Table:

| Method | Key Benefit | Ideal Application |

|---|---|---|

| Epoxy Edge Reinforcement | Prevents crack propagation and fraying | Fuel cell assembly, electrochemical testing |

| Careful Handling | Minimizes initial damage | General use and storage |

| Proper Storage | Reduces environmental degradation | Long-term preservation |

Maximize the performance and lifespan of your carbon paper components with KINTEK solutions.

Our expertise in lab equipment and consumables ensures you have access to the right materials and techniques for demanding applications like fuel cell research and electrochemistry. Let our specialists help you implement best practices for material durability and reliability.

Contact KINTEK today to discuss your specific needs and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Carbon Graphite Boat -Laboratory Tube Furnace with Cover

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What are the advantages of biomass? Unlock Renewable Power from Waste and Crops

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids

- What are the properties of the graphite? Unlock High-Temperature Strength & Conductivity

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage