To clean a PVD finish safely, you only need mild dish soap, water, and a soft cloth or non-scratch sponge. The key is to perform this simple cleaning regularly, rinsing the surface thoroughly with water and wiping it dry afterward. This gentle approach is all that is required to remove residue and maintain the original look of the finish without causing damage.

The core principle of PVD maintenance is simple: its exceptional durability means it does not require aggressive cleaning. Your goal is to gently lift surface residue like soap scum or fingerprints, not to scrub a delicate surface. Harsh chemicals and abrasive tools are unnecessary and counterproductive.

Understanding the PVD Finish

To clean this material correctly, it helps to understand what it is. A PVD (Physical Vapor Deposition) finish is not a traditional paint or plating.

It's a Molecular Bond

PVD is a high-tech process that molecularly bonds a thin, durable layer of metal onto a base material, such as brass or stainless steel. This creates an incredibly hard surface that is integral to the product itself.

Designed for Extreme Durability

This process results in one of the most durable decorative finishes available. It is highly resistant to the scratches, tarnishing, and corrosion that can affect traditional plated finishes.

Why Gentle Cleaning Works

Because the PVD surface is so dense and non-porous, dirt and grime sit on top of it rather than penetrating. A mild detergent is sufficient to break the surface tension and lift this residue away without any need for harsh force.

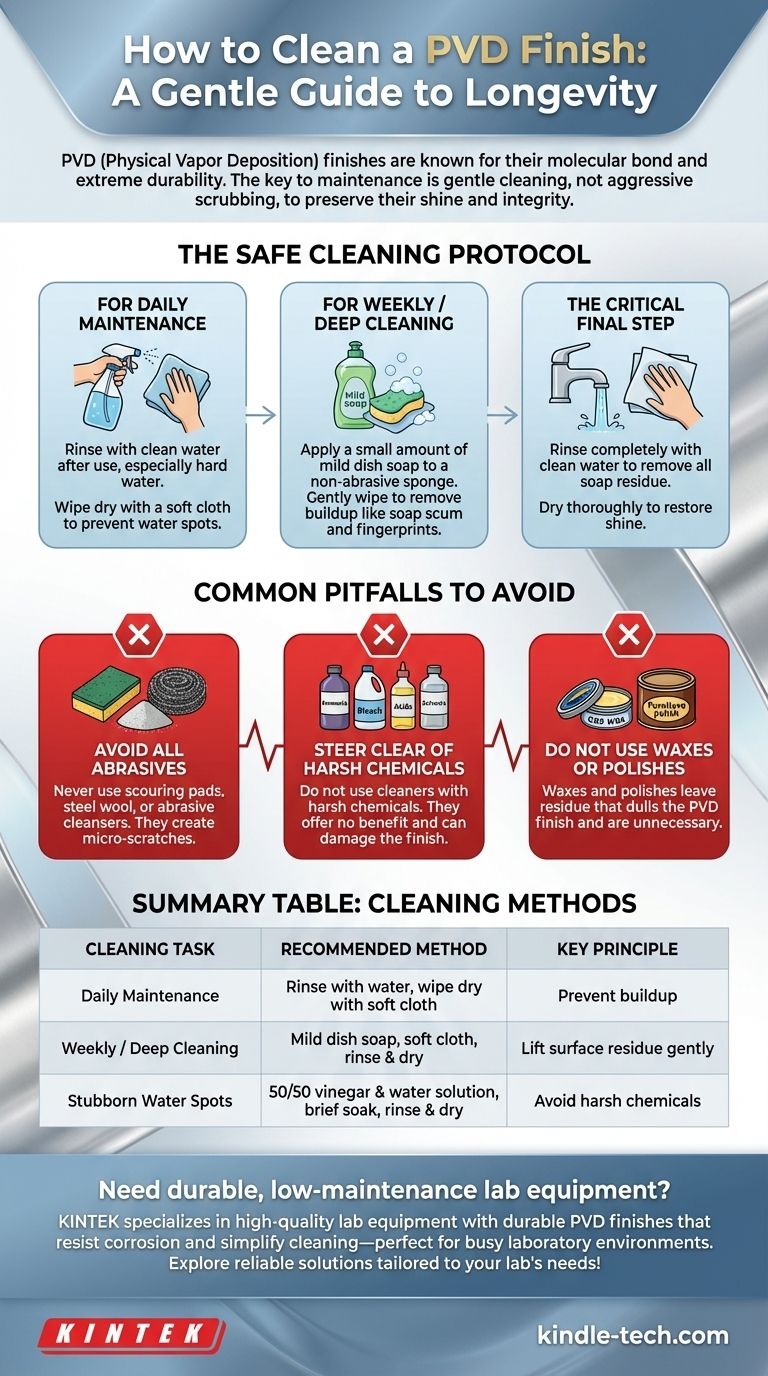

The Safe Cleaning Protocol

Follow this simple, two-level approach to keep your PVD-finished items looking new.

For Daily Maintenance

Rinse the surface with clean water after use, especially in areas with hard water. Wiping it dry with a soft, microfiber cloth is the best way to prevent mineral deposits and water spots from forming.

For Weekly or Deeper Cleaning

Apply a small amount of mild dish soap to a non-abrasive sponge or soft cloth. Gently wipe the surface to remove any buildup, such as soap scum or fingerprints.

The Critical Final Step

Always rinse the surface completely with clean water to remove any remaining soap residue. Failing to rinse can leave a dull film. Dry the fixture thoroughly with a soft cloth to restore its shine and prevent water spots.

Common Pitfalls to Avoid

The most common mistakes in PVD care come from using cleaning methods that are too aggressive.

Avoid All Abrasives

Never use scouring pads, steel wool, or abrasive powder or cream cleansers. While PVD is scratch-resistant, these materials can create micro-scratches that will dull the finish over time.

Steer Clear of Harsh Chemicals

Do not use cleaners containing ammonia, bleach, acids, or harsh solvents. These chemicals offer no benefit for cleaning PVD and can potentially damage the finish with prolonged exposure. Mild soap is all you need.

Do Not Use Waxes or Polishes

Waxes and polishes are designed for other types of surfaces and can leave a residue that dulls the PVD finish. They are unnecessary and interfere with the natural properties of the surface.

Making the Right Choice for Your Goal

Adapt your method based on the specific cleaning task at hand.

- If your primary focus is daily upkeep: Simply rinse the surface with water after use and wipe it dry with a soft cloth to prevent buildup.

- If your primary focus is removing soap scum or fingerprints: Use a soft cloth with a solution of mild dish soap and warm water, then rinse and dry thoroughly.

- If your primary focus is removing stubborn hard water spots: Apply a 50/50 solution of white vinegar and water, let it sit for only a few minutes, then rinse completely with water and dry.

By respecting the inherent strength of the PVD finish with a gentle cleaning routine, you will easily preserve its integrity and appearance for years to come.

Summary Table:

| Cleaning Task | Recommended Method | Key Principle |

|---|---|---|

| Daily Maintenance | Rinse with water, wipe dry with soft cloth | Prevent buildup |

| Weekly/Deep Cleaning | Mild dish soap, soft cloth, rinse & dry | Lift surface residue gently |

| Stubborn Water Spots | 50/50 vinegar & water solution, brief soak, rinse & dry | Avoid harsh chemicals |

Need durable, low-maintenance lab equipment with PVD-finished components? KINTEK specializes in high-quality lab equipment and consumables, featuring durable PVD finishes that resist corrosion and simplify cleaning—perfect for busy laboratory environments. Contact us today to explore our reliable solutions tailored to your lab's needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Graphite Vacuum Continuous Graphitization Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability