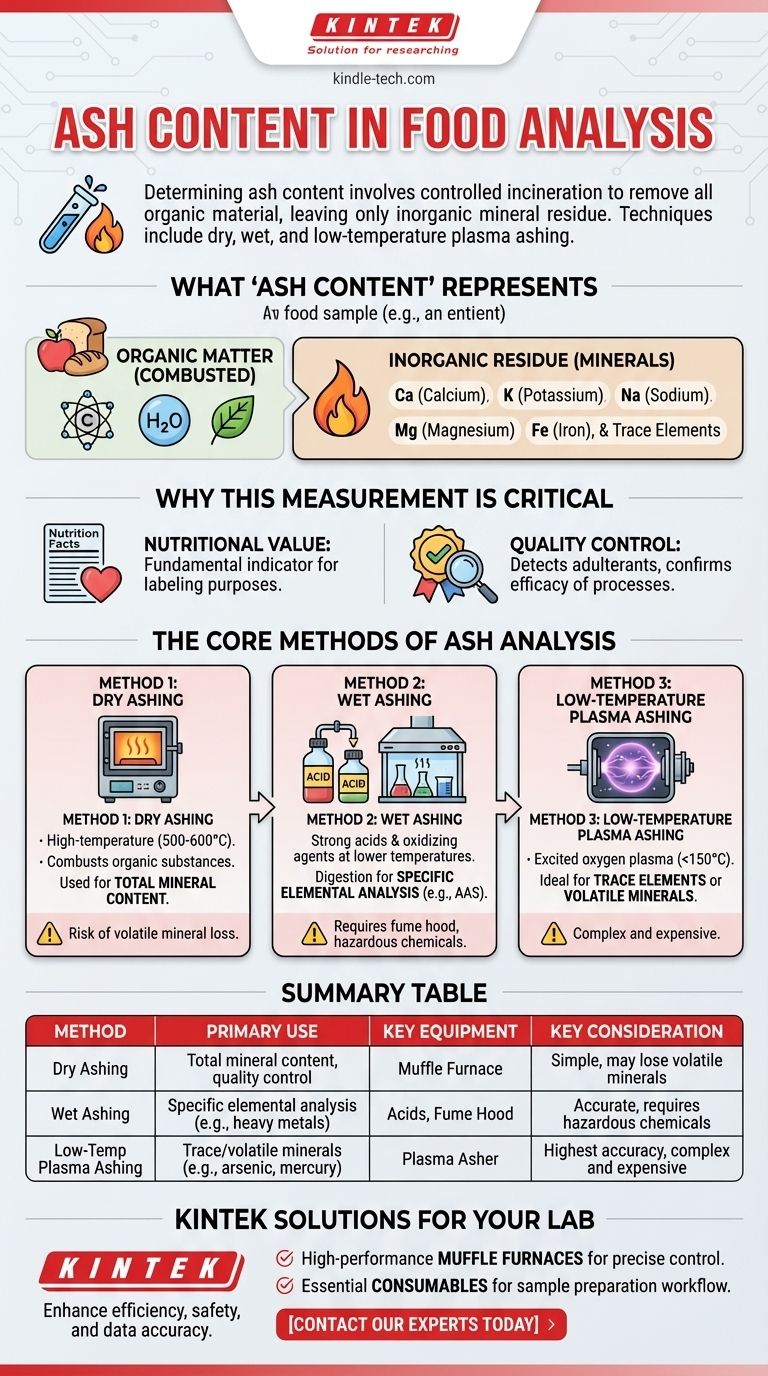

To determine the ash content of a food sample, the most common methods involve controlled incineration to burn off all organic material, leaving only the inorganic mineral residue. The primary techniques are dry ashing, wet ashing, and low-temperature plasma ashing, each selected based on the specific goals of the analysis.

Ash analysis is a foundational technique in food science for quantifying the total mineral content. The core principle is the complete removal of organic matter (carbon, hydrogen, nitrogen) through oxidation, which allows for the measurement of the noncombustible inorganic residue.

What "Ash Content" Actually Represents

Beyond Combustion: The Inorganic Residue

The term "ash" refers to the total amount of minerals present within a food. This residue is what remains after all water and organic material—like protein, fat, and carbohydrates—have been completely incinerated.

This inorganic residue consists of the oxides, sulfates, phosphates, and chlorides of essential minerals such as calcium, potassium, sodium, magnesium, and iron, as well as trace elements.

Why This Measurement is Critical

Measuring ash content is not just an academic exercise; it is a critical parameter in food quality and safety. It serves as a fundamental indicator of nutritional value, as it represents the food's total mineral content for labeling purposes.

Furthermore, it is a key metric in quality control. Unusually high or low ash content can indicate the presence of adulterants, such as sand in spices, or confirm the efficacy of processes like the milling of flour.

The Core Methods of Ash Analysis

The choice of method is dictated by the specific minerals being analyzed and the nature of the food sample itself.

Method 1: Dry Ashing

This is the most common and straightforward method. The food sample is placed in a high-temperature muffle furnace, typically at temperatures between 500 and 600°C.

The extreme heat combusts all organic substances, leaving behind a stable inorganic ash that can be weighed. This method is widely used for determining total mineral content.

Method 2: Wet Ashing

Wet ashing is primarily used when a sample needs to be prepared for the analysis of specific individual minerals, often using techniques like atomic absorption spectroscopy (AAS).

Instead of high heat, this method uses a combination of strong acids (like nitric and sulfuric acid) and oxidizing agents at lower temperatures to digest the organic matter. This keeps the minerals in a solution, ready for further analysis.

Method 3: Low-Temperature Plasma Ashing

This is a more specialized and gentle technique. It uses a vacuum chamber where oxygen is excited into a plasma state using electromagnetic radiation.

This excited oxygen effectively oxidizes the organic material at much lower temperatures (typically <150°C). This process is ideal for analyzing trace elements or volatile minerals (like mercury, lead, or arsenic) that might be lost at the high temperatures of a muffle furnace.

Understanding the Trade-offs

No single method is universally superior; each involves critical trade-offs that you must consider based on your analytical goals.

Accuracy vs. Simplicity

Dry ashing is simple, requires less hands-on time, and can handle larger sample batches. However, the high temperatures can cause the loss of volatile minerals, potentially underestimating their true concentration.

Wet ashing and low-temperature ashing are more complex and labor-intensive but provide a more accurate quantification of volatile or trace elements.

Safety and Equipment

Dry ashing requires a specialized high-temperature muffle furnace, which is a significant capital investment but is relatively safe to operate with standard precautions.

Wet ashing, on the other hand, involves highly corrosive acids and produces noxious fumes, mandating the use of a certified fume hood and rigorous safety protocols.

Making the Right Choice for Your Goal

Your objective dictates the appropriate method.

- If your primary focus is routine quality control or total mineral content for a nutrition label: Dry ashing is the most efficient and practical choice.

- If your primary focus is preparing a sample for specific elemental analysis (e.g., heavy metals or trace nutrients): Wet ashing is the standard procedure to prevent mineral loss and prepare a sample solution.

- If your primary focus is research involving highly volatile minerals in sensitive samples: Low-temperature plasma ashing offers the highest accuracy, though it is the most complex and expensive method.

Ultimately, selecting the correct ashing method is the first critical step in accurately characterizing the nutritional and quality profile of a food product.

Summary Table:

| Method | Primary Use | Key Equipment | Key Consideration |

|---|---|---|---|

| Dry Ashing | Total mineral content, quality control | Muffle Furnace | Simple, but may lose volatile minerals |

| Wet Ashing | Specific elemental analysis (e.g., heavy metals) | Acids, Fume Hood | Accurate, but requires hazardous chemicals |

| Low-Temp Plasma Ashing | Trace/volatile minerals (e.g., arsenic, mercury) | Plasma Asher | Highest accuracy, but complex and expensive |

Ready to Optimize Your Food Analysis Lab?

Choosing the right ashing method is critical for accurate nutritional labeling and quality control. KINTEK specializes in providing the reliable lab equipment you need to execute these methods precisely.

- For Dry Ashing: Our high-performance muffle furnaces offer the precise temperature control and uniform heating required for consistent results.

- For Sample Preparation: We supply essential consumables to support your entire workflow.

We understand the challenges of food science laboratories. Let us help you enhance your lab's efficiency, safety, and data accuracy.

Contact our experts today to discuss your specific needs and find the perfect solution for your lab.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a high-temperature sintering furnace play in NCM cathode synthesis? Optimize Battery Material Quality

- Does tempering reduce hardness? A Deliberate Trade-Off for Superior Toughness

- What is the use of muffle furnace in food analysis? Master Ashing for Accurate Mineral Content

- What role does a high-temperature box furnace play during the re-austenitization of 17-4 PH? Transform SLM Performance

- Why is a high-precision high-temperature furnace required for photosensitive glass? Master Controlled Crystallization

- What role do high-temperature experimental furnaces play in the quenching and aging of Fe-Cr-Ni alloys? | KINTEK

- What is the function of a box furnace in Li6PS5Cl synthesis? Master Post-Treatment for Solid-State Electrolytes

- How does a muffle furnace influence Na2Ni2TeO6 & Na2Zn2TeO6? Optimize Solid Electrolyte Sintering