First and foremost, you cannot safely or effectively fix a broken ceramic tooth yourself. A broken ceramic restoration, such as a crown or veneer, requires immediate professional dental care to prevent further damage, pain, or infection. The specific repair method a dentist will use depends entirely on the location and severity of the fracture, as well as the condition of the natural tooth underneath.

A broken ceramic tooth is not a DIY project. The only correct action is to see a dentist who will assess the damage and determine the best solution, which can range from simple polishing for a micro-chip to a full replacement of the crown or veneer for a significant fracture.

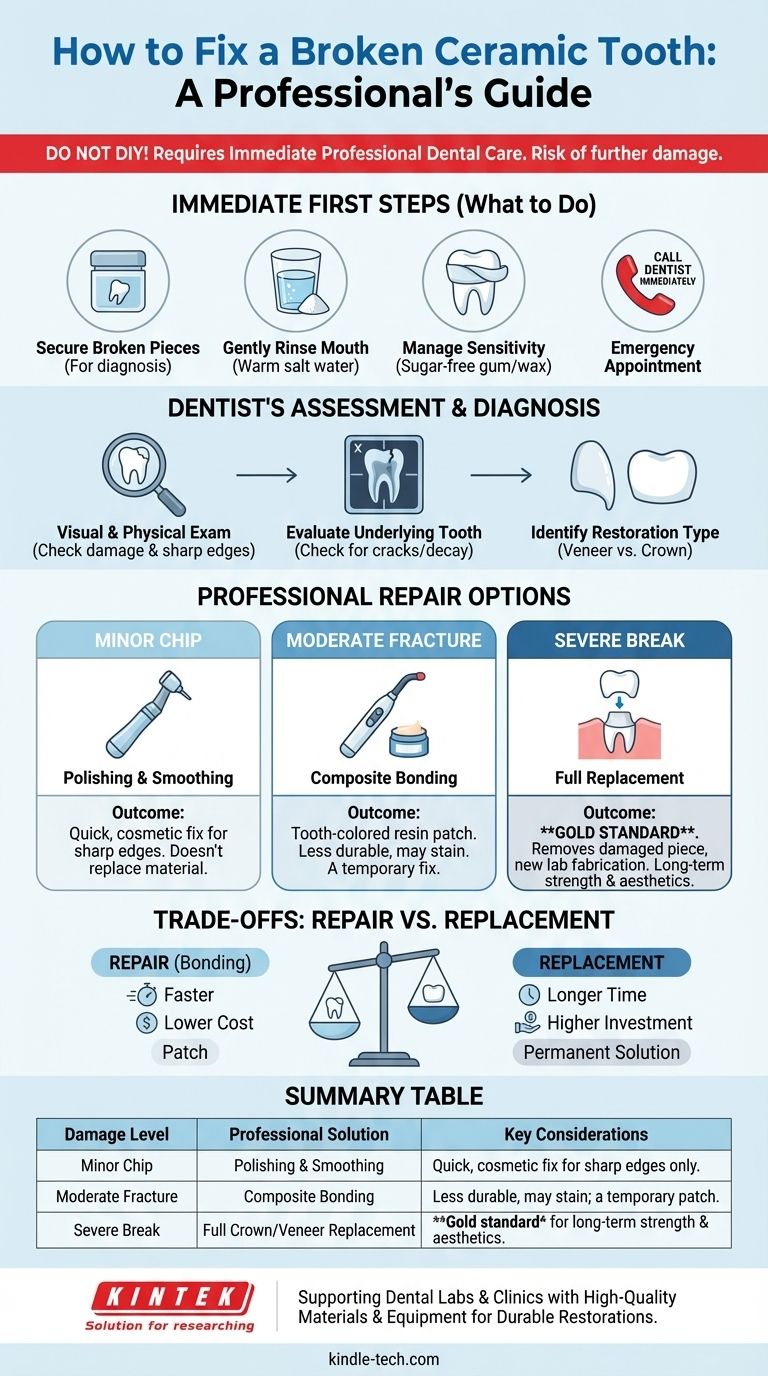

First Steps: What to Do Immediately

A broken crown or veneer can be alarming. Taking the right immediate steps can protect your tooth and make the professional repair process smoother.

Secure Any Broken Pieces

If you can find the piece that broke off, wrap it in a clean tissue or place it in a small, hard-sided container. Bring this with you to your dental appointment, as it can help your dentist diagnose the cause of the fracture.

Gently Rinse Your Mouth

Rinse your mouth with warm salt water. This helps to clean the area and can soothe any irritation to your gums or the inside of your cheek.

Manage Sensitivity

If the underlying natural tooth is exposed, it may be sensitive to temperature or air. You can temporarily cover the area with sugar-free gum or dental wax, which is available at most pharmacies. This is a temporary measure only while you await your appointment.

Call Your Dentist Immediately

This is the most critical step. Explain the situation and schedule an emergency appointment. The sooner you are seen, the better the chances of a simple and successful resolution.

How a Dentist Assesses the Damage

When you see your dentist, they will perform a thorough evaluation to determine the best course of action. This is a diagnostic process, not a one-size-fits-all repair.

Visual and Physical Examination

Your dentist will examine the broken restoration to see the extent of the damage. They will check for sharp edges that could injure your tongue or cheek and assess the integrity of the remaining ceramic.

Evaluating the Underlying Tooth

The most important factor is the health of your natural tooth beneath the ceramic. Your dentist will check to ensure it has not been damaged or compromised. An x-ray is often necessary to look for cracks in the tooth root or signs of decay.

Identifying the Restoration Type

The repair strategy differs for a veneer (a thin shell on the front of the tooth) versus a crown (which covers the entire tooth). A dentist needs to know what they are working with to recommend the right treatment.

Common Professional Repair Options

Based on the diagnosis, your dentist will recommend one of several solutions. These are always performed in a clinical setting.

For Minor Chips: Polishing and Smoothing

If the chip is very small and purely cosmetic, a dentist can often use specialized polishing tools to smooth the sharp edge. This restores a comfortable feel and prevents further chipping, though it doesn't replace the lost material.

For Moderate Fractures: Composite Bonding

For larger chips, a dentist may be able to repair the ceramic by bonding a tooth-colored composite resin to the damaged area. While this can be a quick and cost-effective fix, the bonded material is not as strong as ceramic and may be more prone to staining or future breakage.

For Severe Breaks: Full Replacement

In most cases of a significant fracture, the only durable, long-term solution is to completely replace the crown or veneer. This involves removing the damaged restoration, preparing the tooth again, taking a new impression, and fabricating a brand-new ceramic tooth in a dental lab. This is the gold standard for both strength and aesthetics.

Understanding the Trade-offs

Choosing a treatment path involves balancing longevity, cost, and time.

Repairing vs. Replacing

A composite bonding repair is faster and less expensive upfront, but it is a patch. A full replacement is a more significant investment of time and money but restores the original strength and appearance of the tooth for the long term. The bond between composite and ceramic is never as strong as the ceramic itself.

The Cost Factor

Costs vary dramatically based on the chosen solution. Polishing is minimal, bonding is moderate, and a full replacement is the most significant investment. Your dental insurance and geographic location will also play a role.

The Time Commitment

A repair with bonding can often be done in a single visit. A full replacement of a crown or veneer typically requires two visits: one for preparation and impressions, and a second to bond the final, lab-made restoration.

Making the Right Choice for Your Goal

Your conversation with your dentist will guide the final decision. The right path depends on the specific damage and your personal priorities.

- If the break is a tiny, non-sensitive chip: A professional check is vital to rule out hidden cracks, but you may only require simple polishing.

- If a noticeable piece has broken off: A composite bonding repair is a possibility, but a full replacement offers the best long-term strength and cosmetic result.

- If you are in pain or the natural tooth is exposed: This is a dental emergency requiring immediate attention to prevent infection and save the underlying tooth.

Seeking professional care is the only way to safely restore your tooth's function, health, and appearance.

Summary Table:

| Damage Level | Professional Solution | Key Considerations |

|---|---|---|

| Minor Chip | Polishing & Smoothing | Quick, cosmetic fix for sharp edges only. |

| Moderate Fracture | Composite Bonding | Less durable, may stain; a temporary patch. |

| Severe Break | Full Crown/Veneer Replacement | Gold standard for long-term strength & aesthetics. |

Don't risk further damage to your tooth. A broken ceramic restoration is a dental emergency that requires professional care.

If you are a dental lab or clinic seeking high-quality materials and equipment for creating durable ceramic restorations, KINTEK is here to support you. We specialize in providing reliable lab equipment and consumables that help dental professionals achieve precise, long-lasting results for their patients.

Contact our experts today to discuss how our solutions can enhance your dental lab's capabilities and ensure the best outcomes for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects