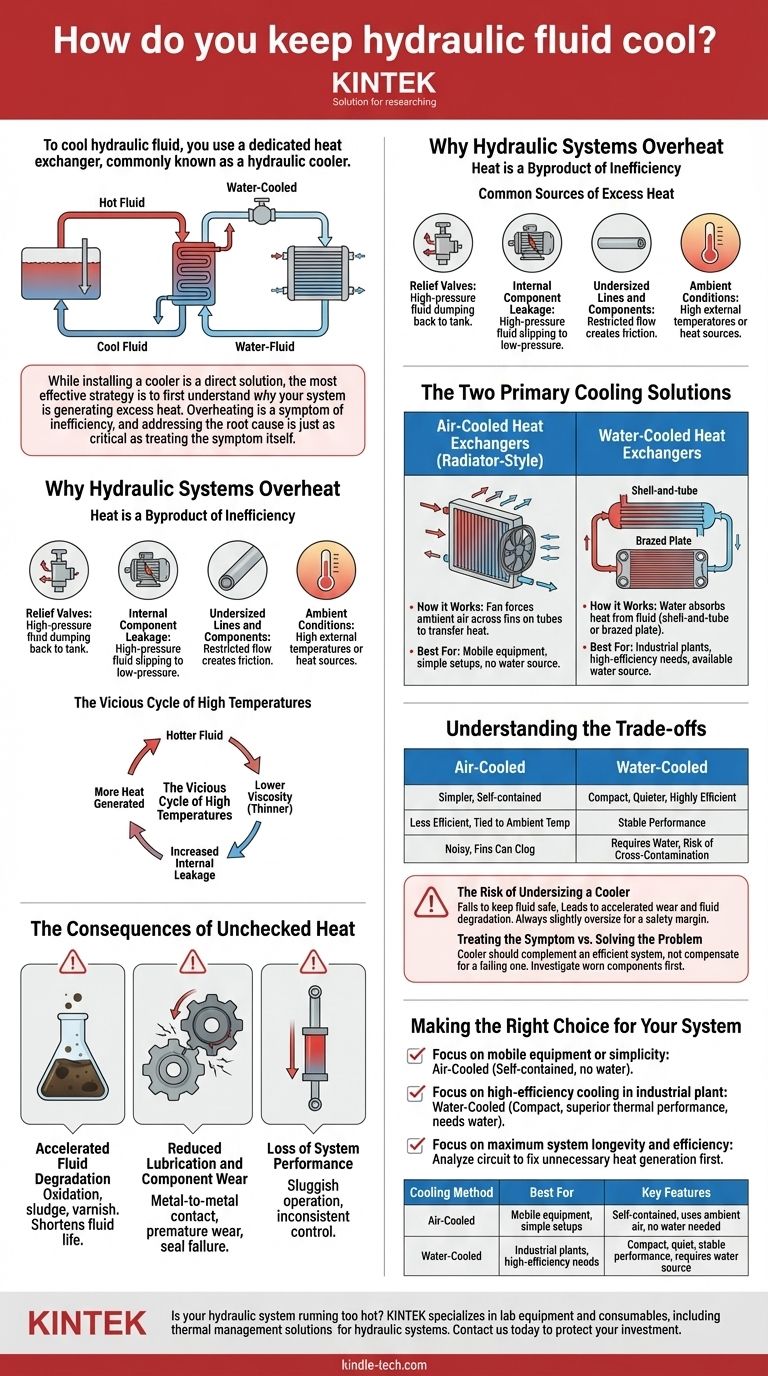

To cool hydraulic fluid, you use a dedicated heat exchanger, commonly known as a hydraulic cooler. The two primary types are air-cooled and water-cooled, which function by transferring waste heat from the hydraulic fluid to the surrounding air or a separate water circuit. This process is critical for maintaining the fluid's specified viscosity and preventing thermal damage to system components.

While installing a cooler is a direct solution, the most effective strategy is to first understand why your system is generating excess heat. Overheating is a symptom of inefficiency, and addressing the root cause is just as critical as treating the symptom itself.

Why Hydraulic Systems Overheat

Understanding the source of heat is the first step toward effective thermal management. Heat is not an external enemy; it's an internal byproduct of the work your system performs.

Heat is a Byproduct of Inefficiency

Every hydraulic system generates some heat, as no system is 100% efficient. This heat is the result of energy loss. It occurs any time fluid flow is restricted or turbulent, converting hydraulic energy (pressure) into thermal energy (heat).

Common Sources of Excess Heat

The most significant heat generation comes from pressure drops that don't perform useful work. Key sources include:

- Relief Valves: A relief valve dumping high-pressure fluid directly back to the tank is a primary source of heat.

- Internal Component Leakage: As pumps, motors, and valves wear, internal leakage increases. This high-pressure fluid slipping to a low-pressure side generates significant heat.

- Undersized Lines and Components: Hoses, tubes, and valves that are too small for the required flow rate create friction and pressure loss, which manifests as heat.

- Ambient Conditions: High external temperatures or placing the hydraulic power unit near other heat sources (like an engine) reduces the system's ability to dissipate heat naturally.

The Vicious Cycle of High Temperatures

As hydraulic fluid gets hotter, its viscosity (thickness) decreases. This thinner fluid increases internal leakage in pumps and motors, which reduces their efficiency and generates even more heat. This feedback loop can cause temperatures to spiral upwards quickly if not controlled.

The Consequences of Unchecked Heat

Operating a hydraulic system above its recommended temperature (typically 180°F or 82°C) is not a minor issue. It leads to accelerated wear, component failure, and costly downtime.

Accelerated Fluid Degradation

High temperatures drastically shorten the life of hydraulic fluid. The oil oxidizes, forming sludge and varnish that can clog filters, stick valves, and coat internal surfaces, impairing heat dissipation even further.

Reduced Lubrication and Component Wear

When fluid thins out due to heat, its lubricating film weakens. This leads to increased metal-to-metal contact in pumps, motors, and cylinders, causing premature wear and eventual failure. Elastomeric seals also harden and crack, leading to leaks.

Loss of System Performance

A hot, thin fluid results in sluggish and inconsistent machine operation. Actuator speeds may decrease, and precise control can be lost as more fluid bypasses internal clearances instead of doing useful work.

The Two Primary Cooling Solutions

When a system's heat generation exceeds its natural ability to dissipate it, a cooler is necessary. The choice between air and water cooling depends on the application, environment, and required efficiency.

Air-Cooled Heat Exchangers

These coolers, also known as radiator-style coolers, pass hydraulic fluid through a series of tubes. A fan, powered by an electric or hydraulic motor, forces ambient air across fins attached to the tubes, transferring heat from the fluid to the air.

They are the most common solution for mobile equipment and in locations where a steady supply of cooling water is unavailable.

Water-Cooled Heat Exchangers

These devices use water to absorb heat from the hydraulic fluid. The two main types are shell-and-tube and brazed plate coolers.

- Shell-and-tube: Fluid flows through a bundle of tubes while water circulates around the outside of the tubes within a larger shell.

- Brazed plate: Corrugated plates are stacked and brazed together, creating alternating channels for the hot fluid and cool water. They are extremely efficient and compact.

Water-cooled units are common in industrial, stationary applications where high heat loads require more cooling capacity than an air cooler of a similar size can provide.

Understanding the Trade-offs

Selecting a cooling solution involves balancing efficiency, cost, and environmental factors. A mistake here can lead to either wasted capital or system failure.

Air-Cooled vs. Water-Cooled

Air coolers are simpler and self-contained but are less efficient and their performance is directly tied to the ambient air temperature. They can also be noisy and their fins are prone to clogging in dirty environments.

Water coolers are more compact, quieter, and highly efficient. Their performance is stable regardless of air temperature. However, they require a reliable source of clean, cool water and carry a small risk of cross-contamination between the water and oil circuits if an internal leak develops.

The Risk of Undersizing a Cooler

Attempting to save money with an undersized cooler is a critical error. An undersized unit will fail to keep the fluid at a safe operating temperature, leading to the exact component wear and fluid degradation you are trying to prevent. It is always better to slightly oversize a cooler to ensure a robust safety margin.

Treating the Symptom vs. Solving the Problem

Adding a cooler is often the fastest way to solve an overheating problem, but it may just be masking a significant system inefficiency. If a system that once ran cool now overheats, investigate worn components or changed operating parameters first. A cooler should complement an efficient system, not compensate for a failing one.

Making the Right Choice for Your System

Your cooling strategy must align with your equipment, environment, and performance goals.

- If your primary focus is mobile equipment or simplicity: Air-cooled coolers are the standard choice due to their self-contained design and independence from a water source.

- If your primary focus is high-efficiency cooling in an industrial plant: Water-cooled plate or shell-and-tube coolers offer superior thermal performance in a more compact package, assuming a water source is available.

- If your primary focus is maximum system longevity and efficiency: Always begin by analyzing your circuit to find and fix sources of unnecessary heat generation before sizing and installing any cooler.

A well-managed thermal state is the foundation of a reliable and efficient hydraulic system.

Summary Table:

| Cooling Method | Best For | Key Features |

|---|---|---|

| Air-Cooled | Mobile equipment, simple setups | Self-contained, uses ambient air, no water needed |

| Water-Cooled | Industrial plants, high-efficiency needs | Compact, quiet, stable performance, requires water source |

Is your hydraulic system running too hot? KINTEK specializes in lab equipment and consumables, including thermal management solutions for hydraulic systems in laboratory and industrial settings. Our expertise ensures your equipment operates efficiently and reliably. Contact us today to discuss your cooling needs and protect your investment!

Visual Guide

Related Products

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Vacuum Cold Trap Direct Cold Trap Chiller

- Touchscreen Automatic Vacuum Heat Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- Why is a circulating water cooling system required for photocatalytic hydrogen peroxide? Stability and Yield Explained

- How do cooling systems impact bio-oil collection? Maximize Pyrolysis Yield with Precision Multi-Stage Quenching

- Why is a high-precision ultra-low temperature cooling system necessary for FATT50? Ensure Precise Material Transition

- Why are internal cooling coils used after hydrothermal treatment? Unlock Higher Yields in Biomass Processing

- What is the cooling system of an induction furnace? Essential for Safe, Reliable Melting