Maintaining a constant laboratory temperature is achieved by using a hierarchy of controls, ranging from large-scale environmental systems to highly specialized benchtop equipment. The primary tools include laboratory-grade HVAC systems for ambient room stability, supplemented by incubators, water baths, and refrigeration units to create precise micro-environments for specific samples and experiments.

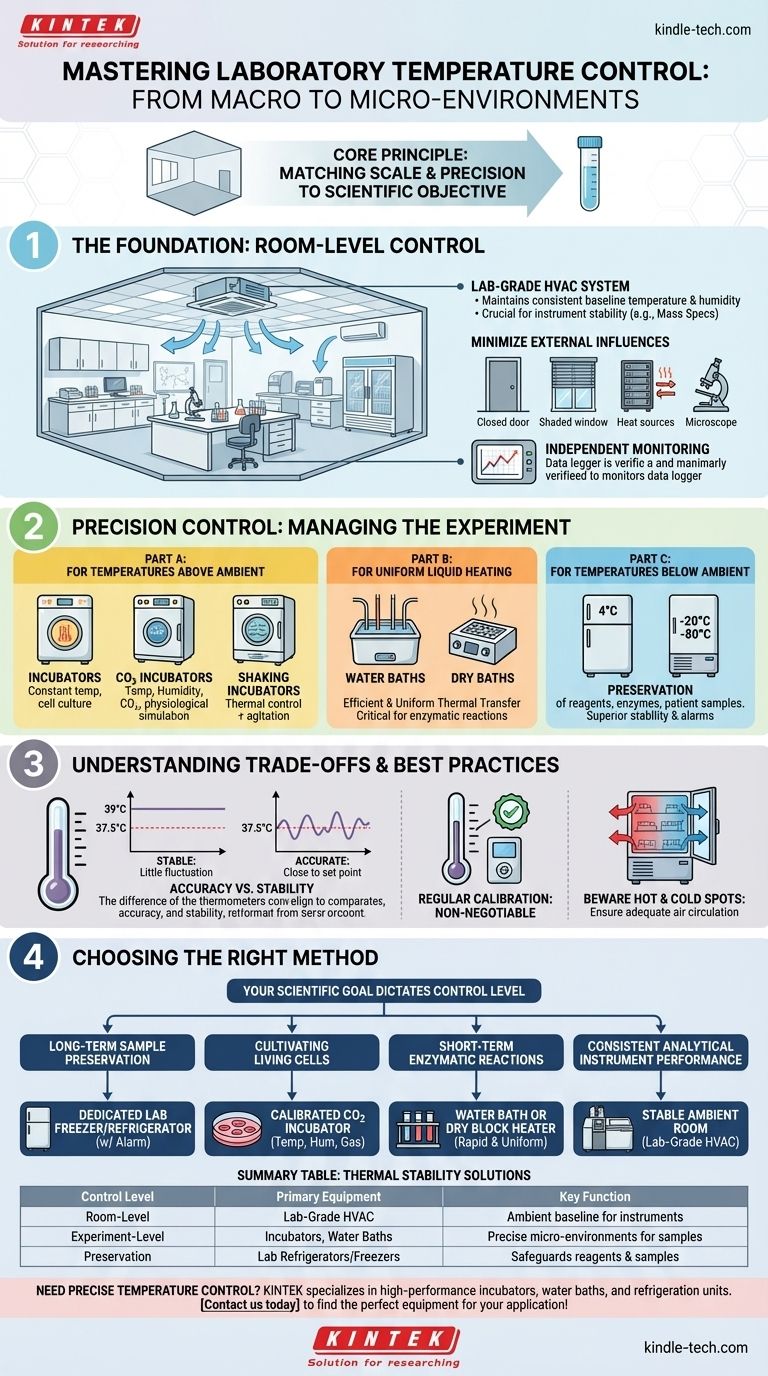

The core principle of lab temperature control is not about finding a single solution, but about matching the required scale and precision to the scientific objective—from stabilizing an entire room to precisely managing the temperature of a few microliters in a test tube.

The Foundation: Room-Level Control

Controlling the ambient temperature of the laboratory itself is the first and most critical layer of thermal stability. Fluctuations in the room can directly impact instrument performance and place unnecessary strain on benchtop equipment.

The Role of Lab-Grade HVAC

A laboratory's Heating, Ventilation, and Air Conditioning (HVAC) system is a scientific instrument, not just a comfort system. It is designed to maintain a consistent baseline temperature and humidity across the entire space, often with much tighter tolerances than a commercial or residential unit.

This stable baseline is essential for the proper operation of sensitive analytical instruments like mass spectrometers, chromatographs, and microscopes, which can drift or lose calibration with ambient temperature swings.

Minimizing External Influences

Simple procedural discipline is crucial for supporting the HVAC system. This includes keeping doors to hallways closed, ensuring windows are sealed and shielded from direct sunlight, and strategically placing heat-generating equipment (like large freezers or computer racks) away from sensitive experimental areas.

Verifying with Independent Monitoring

Trusting the thermostat setting is not sufficient for rigorous scientific work. Independent and calibrated thermometers or data loggers should be placed in key areas of the lab to continuously monitor and record the ambient temperature, providing an objective record of environmental conditions.

Precision Control: Managing the Experiment

While the room provides a stable baseline, most experiments require far more precise temperature control. This is accomplished with specialized benchtop equipment designed to manage the immediate environment of the samples.

For Temperatures Above Ambient

Incubators are enclosed chambers used to maintain a constant temperature for applications like cell cultures or microbial growth. CO2 incubators go a step further, also controlling humidity and carbon dioxide levels to simulate physiological conditions. For applications requiring agitation, shaking incubators provide both thermal control and consistent mixing.

For Uniform Liquid Heating

Water baths and dry baths (using beads or blocks) are the workhorses for heating samples in tubes, flasks, or beakers. They provide highly efficient and uniform thermal transfer, ensuring that the entire sample quickly reaches and maintains the target temperature. This is critical for enzymatic reactions and chemical synthesis.

For Temperatures Below Ambient

Standard laboratory refrigerators (typically 4°C) and freezers (-20°C to -80°C) are essential for preserving the integrity of reagents, enzymes, antibodies, and patient samples. Unlike domestic units, they are built for superior temperature stability and often include alarms to warn of failures.

Understanding the Trade-offs and Best Practices

Simply purchasing equipment is not enough to guarantee thermal stability. Understanding the limitations and implementing rigorous procedures is what separates reliable research from failed experiments.

Accuracy vs. Stability

These two terms are not interchangeable. Stability refers to how little the temperature fluctuates around a set point. Accuracy refers to how close that set point is to the true temperature. A water bath could be very stable at a displayed 37.5°C but, if inaccurate, actually be holding a stable 39°C.

The Critical Role of Calibration

All temperature control devices drift over time. Regular calibration is non-negotiable in a regulated or quality-focused lab. This involves using a certified reference thermometer to check the equipment's accuracy and adjusting it as necessary to ensure it performs to specification.

Beware of Hot and Cold Spots

The temperature displayed on a device's screen does not guarantee the temperature is uniform inside. Poor air circulation in an incubator or overloading a freezer can create significant hot and cold spots, jeopardizing the samples within. Always ensure there is adequate space for circulation around your items.

Choosing the Right Method for Your Experiment

Your scientific goal dictates the appropriate level of temperature control. Use this guide to make an informed decision.

- If your primary focus is long-term sample preservation: Use a dedicated, monitored laboratory freezer or refrigerator with an alarm system.

- If your primary focus is cultivating living cells: A calibrated CO2 incubator is the only suitable choice to manage temperature, humidity, and gas environment.

- If your primary focus is running short-term enzymatic reactions: A water bath or dry block heater provides the most rapid and uniform temperature control for small-volume samples.

- If your primary focus is ensuring consistent analytical instrument performance: Prioritize a stable ambient room temperature controlled by a well-maintained, lab-grade HVAC system.

Ultimately, achieving thermal stability is about selecting the right tool for the required scale and precision, then verifying its performance through diligent calibration and monitoring.

Summary Table:

| Control Level | Primary Equipment | Key Function |

|---|---|---|

| Room-Level | Lab-Grade HVAC | Maintains stable ambient baseline for instruments |

| Experiment-Level | Incubators, Water Baths | Provides precise micro-environments for samples |

| Preservation | Lab Refrigerators/Freezers | Safeguards reagents and samples at specific temperatures |

Need precise temperature control for your laboratory? KINTEK specializes in high-performance lab equipment, including incubators, water baths, and refrigeration units, designed to deliver the stability and accuracy your research demands. Ensure your experiments and samples are protected with reliable thermal management solutions. Contact us today to find the perfect equipment for your specific application!

Visual Guide

Related Products

- Shaking Incubators for Diverse Laboratory Applications

- Laboratory Hybrid Tissue Grinding Mill

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- Why is a constant temperature shaker required during the impregnation of manganese salts onto activated carbon?

- What critical reaction conditions does a shaking incubator provide? Optimize Cassava Cellulose Enzymatic Hydrolysis

- Why is a thermostatic shaker required for SSF of rice husk solids? Maximize Your Ethanol Yield with Precision Agitation

- What is the purpose of a constant temperature incubator shaker? Master Quercetin Adsorption on Nanocomposites

- What function does a constant temperature shaker perform during adsorption performance tests? Ensure Data Accuracy