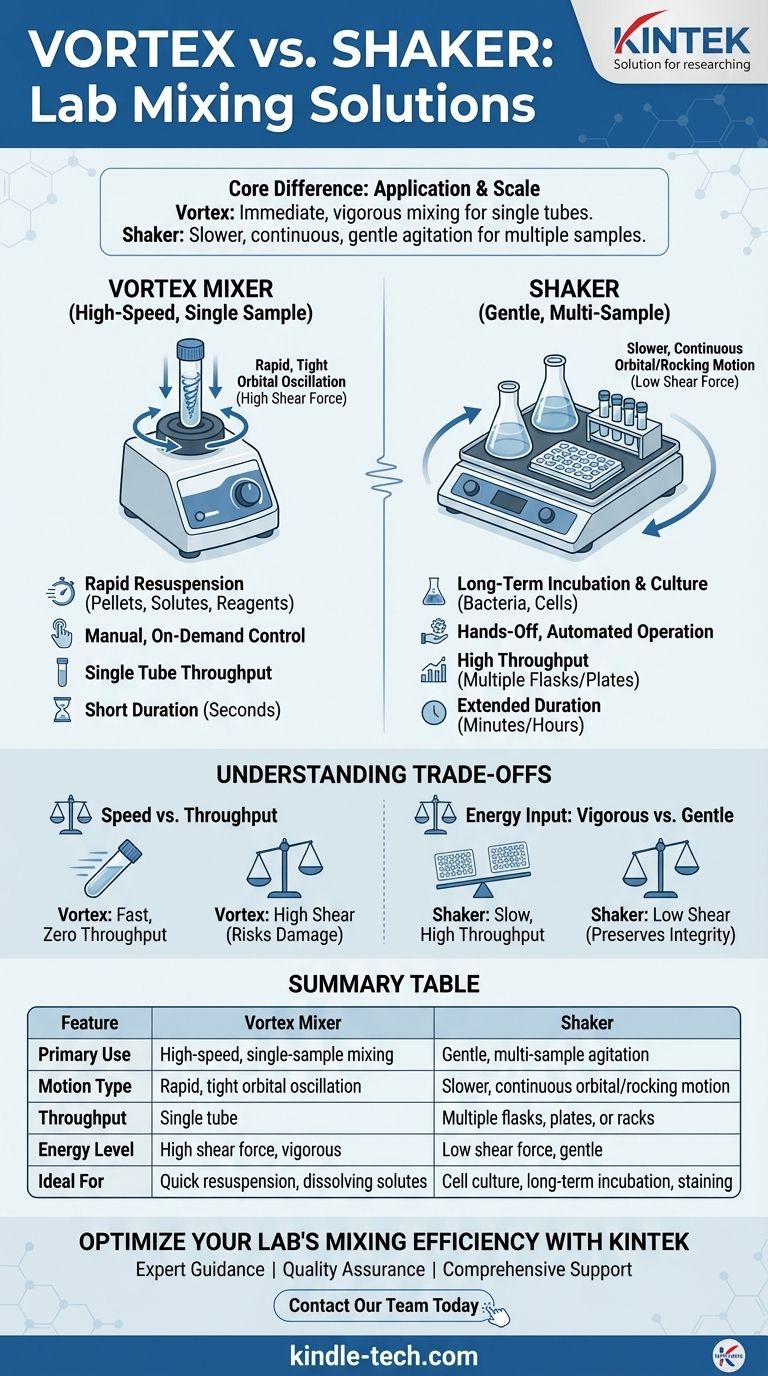

At its core, the difference comes down to application and scale. A vortex mixer uses a small, rapidly oscillating pad to create a powerful vortex within a single tube for immediate, vigorous mixing. In contrast, a shaker uses a larger platform to provide slower, continuous, and gentle agitation to multiple samples at once.

The choice between a vortexer and a shaker is not about which is superior, but which tool matches the required energy and throughput for your specific scientific procedure. Vortexing is for high-energy, single-sample tasks, while shaking is for low-energy, multi-sample processes.

The Core Mechanical Difference: How They Mix

Understanding the physical mechanism of each device immediately clarifies its intended purpose in the laboratory. The design directly dictates the type of mixing energy applied to the sample.

The Vortex Mixer: High-Speed Orbital Motion

A vortex mixer does not have a large platform for holding samples. Instead, it features a small rubber cup or pad.

This pad oscillates in a tight, circular motion at very high speeds. When the user presses a tube against it, that rapid motion is transferred directly into the liquid, creating the characteristic vortex. This action is manually controlled, on-demand, and highly localized to one sample.

The Shaker: Broad, Consistent Agitation

A shaker is built around a platform designed to securely hold multiple flasks, plates, or tube racks.

This entire platform moves in a consistent, slower motion, such as orbital (circular) or rocking (see-saw). This provides uniform, gentle agitation across all samples simultaneously, making it ideal for hands-off, long-duration applications.

Functional Application: When to Use Each Tool

The mechanical differences lead to distinct use cases. Choosing the wrong tool can compromise your results by either failing to mix sufficiently or by damaging sensitive samples.

Use a Vortex for... Rapid Resuspension

The vortex mixer is the go-to tool for tasks requiring a quick, powerful burst of energy.

Its primary uses include resuspending cell pellets after centrifugation, dissolving powders or crystals into a solvent, or quickly mixing reagents within a single tube before a reaction. The process is typically over in seconds.

Use a Shaker for... Long-Term Incubation and Culture

A shaker is essential for processes that require sustained, gentle, and uniform agitation over minutes or hours.

Common applications include growing bacterial or cell cultures that require constant aeration, performing staining and washing steps for gels, or preventing solids from settling out of solution during a long incubation.

Understanding the Trade-offs

Each instrument presents a clear trade-off between speed, force, and sample throughput. Recognizing these limitations is key to experimental design.

Speed vs. Throughput

A vortex mixer is incredibly fast for a single sample but offers zero throughput. Mixing a 96-well plate one tube at a time would be prohibitively time-consuming.

A shaker is much slower to mix a single point, but its value lies in high-throughput capability. It can process dozens of flasks or multiple microplates at once, saving immense hands-on time.

Energy Input: Vigorous vs. Gentle

The vortex introduces a high amount of shear force into the sample. This powerful agitation can denature sensitive proteins or damage delicate cell membranes.

Shakers provide low-shear agitation. This gentle, consistent motion is specifically designed to mix without disrupting the structural integrity of biological samples, making it essential for cell culture.

Making the Right Choice for Your Experiment

Your choice should always be dictated by the specific requirements of your protocol and the nature of your samples.

- If your primary focus is quickly resuspending a pellet or dissolving a solute in one tube: Use a vortex mixer for its speed and power.

- If your primary focus is growing cell cultures or gently agitating many samples for hours: Use an orbital shaker for its consistent, low-shear, high-throughput performance.

- If your primary focus is avoiding damage to sensitive proteins or cells: A gentle shaker is almost always the safer and more appropriate choice.

Ultimately, selecting the correct mixing method is a foundational step toward achieving reliable and reproducible results.

Summary Table:

| Feature | Vortex Mixer | Shaker |

|---|---|---|

| Primary Use | High-speed, single-sample mixing | Gentle, multi-sample agitation |

| Motion Type | Rapid, tight orbital oscillation | Slower, continuous orbital/rocking motion |

| Throughput | Single tube | Multiple flasks, plates, or racks |

| Energy Level | High shear force, vigorous | Low shear force, gentle |

| Ideal For | Quick resuspension, dissolving solutes | Cell culture, long-term incubation, staining |

Optimize Your Lab's Mixing Efficiency with KINTEK

Choosing the right mixing equipment is crucial for achieving consistent, reliable results in your laboratory workflows. Whether you need the high-speed power of a vortex mixer for quick resuspension or the gentle, high-throughput capabilities of a shaker for cell culture, KINTEK has the solution.

Why choose KINTEK for your lab equipment needs?

- Expert Guidance: Our specialists help you select the perfect mixer for your specific applications and sample types

- Quality Assurance: We provide durable, precision-engineered shakers and vortex mixers built for long-term reliability

- Comprehensive Support: From installation to maintenance, we ensure your equipment performs optimally throughout its lifespan

Ready to enhance your lab's mixing capabilities? Contact our team today to discuss your requirements and discover how KINTEK's laboratory equipment solutions can improve your workflow efficiency and experimental outcomes.

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- Shaking Incubators for Diverse Laboratory Applications

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What role does a laboratory shaker play in the extraction of plant compounds for green synthesis? Maximize Your Yield

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance