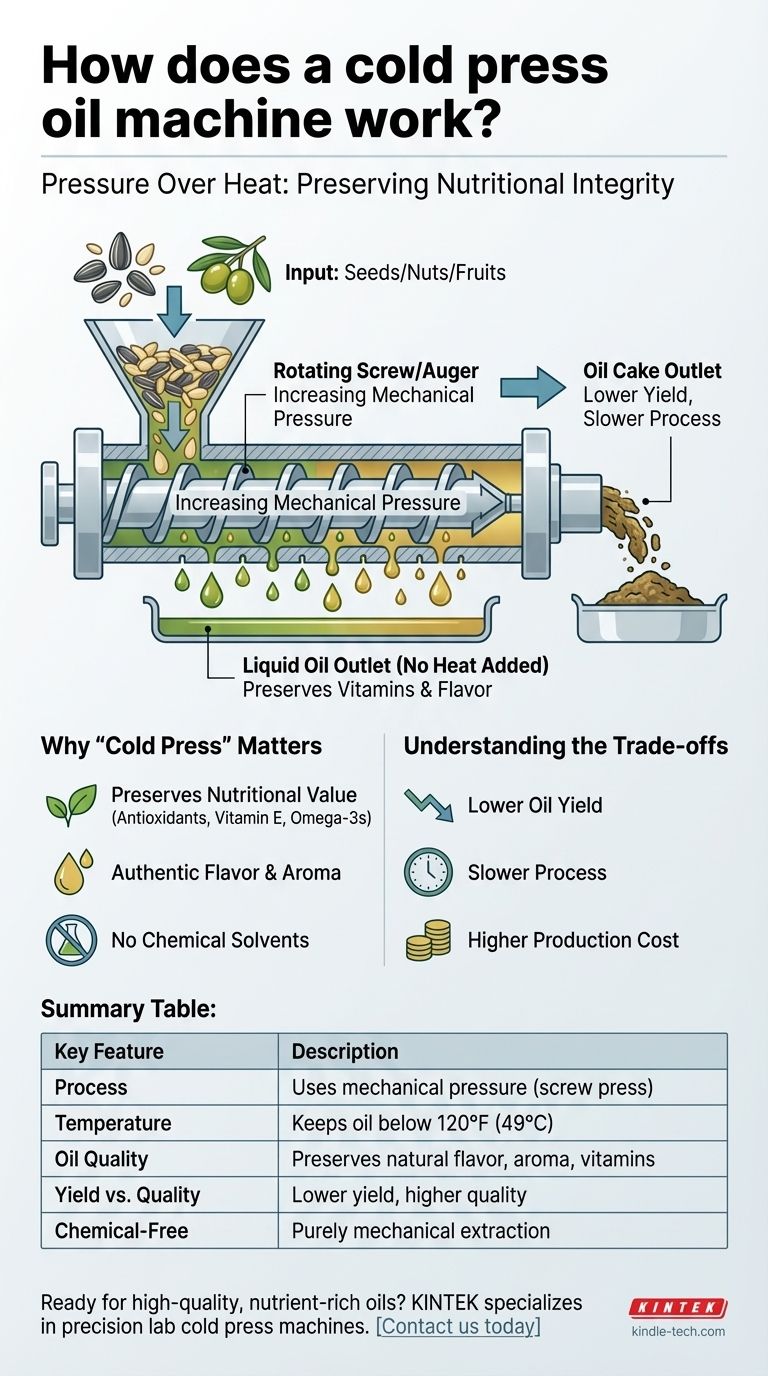

At its core, a cold press oil machine works by using immense mechanical pressure to physically squeeze oil out of seeds, nuts, or fruits without adding external heat. This purely mechanical process is designed to extract the oil in its most natural state, ensuring that the friction generated during extraction does not significantly raise the temperature of the oil.

The entire design philosophy of a cold press machine revolves around one central goal: preserving the oil's nutritional integrity, flavor, and aroma by avoiding the damaging effects of high heat used in conventional extraction methods.

The Mechanical Principle: Pressure Over Heat

The technology behind cold pressing is a modern application of an ancient concept: the screw press. The goal is to maximize force in a controlled way to rupture the oil-bearing cells within the raw material.

The Expeller Press Design

Most modern cold press machines are a type of expeller press. This design uses a rotating screw inside a tightly fitting barrel to crush and press the oil-bearing material.

The Role of the Screw (Auger)

The screw, or auger, is the heart of the machine. As it rotates, it forces the seeds or nuts down the length of the barrel. The design of the screw's threads changes along its path, gradually decreasing the space and thereby building up extreme pressure.

The Barrel and Oil Outlets

The raw material is crushed against the inner wall of the barrel (or chamber). This barrel is perforated with very small openings. The immense pressure forces the liquid oil through these outlets while the solid, fibrous material is retained inside.

Separating Oil from Cake

As the crushed material reaches the end of the barrel, the remaining dry, solid pulp—known as the oil cake—is expelled through a restricted opening. The extracted raw oil is collected separately, ready for filtering and bottling.

Why "Cold Press" Matters for Quality

The term "cold press" is not just a marketing label; it refers to a specific operational standard that has a direct impact on the final product.

Preserving Nutritional Value

Many beneficial compounds in oils, such as antioxidants, vitamins (like Vitamin E), and polyunsaturated fats (like omega-3s), are sensitive to heat. The cold press method keeps temperatures low, typically below 120°F (49°C), preventing these delicate nutrients from degrading.

Maintaining Authentic Flavor and Aroma

High heat can effectively "cook" the oil during extraction, altering its natural taste and smell. Cold pressing preserves the original, often more robust and nuanced, flavor profile of the source material, whether it's an olive, a sesame seed, or a coconut.

No Chemical Solvents

Unlike some large-scale industrial methods that use chemical solvents like hexane to extract the maximum amount of oil, cold pressing is a purely mechanical process. This ensures no chemical residues make their way into the final product.

Understanding the Trade-offs

While cold pressing produces a superior quality oil, the method involves significant trade-offs that explain its higher market price.

Lower Oil Yield

Cold pressing is less efficient than hot pressing or solvent extraction. Without heat to reduce the oil's viscosity and break down cells more effectively, a notable amount of oil is left behind in the discarded oil cake.

Slower Process

The mechanical grinding and pressing process is inherently slower than industrial methods designed for mass production. This lower throughput increases the operational time required to produce the same volume of oil.

Higher Cost

The combination of lower yield (requiring more raw material per liter of oil) and a slower, more energy-intensive process directly translates to a higher production cost, which is passed on to the consumer.

Making the Right Choice for Your Goal

Understanding how a cold press machine works allows you to choose the right oil for your specific needs, recognizing that the extraction method fundamentally defines the product.

- If your primary focus is maximum nutritional value and authentic flavor for dressings, drizzles, or low-heat cooking: Cold-pressed oil is the definitive choice, as its production method is entirely centered on preserving these qualities.

- If your primary focus is high-heat cooking (like deep-frying) or budget-friendliness: A refined oil, which is often hot-pressed or solvent-extracted, may be more suitable due to its higher smoke point and lower cost.

Ultimately, choosing a cold-pressed oil is a deliberate decision to prioritize the quality and integrity of the product over the efficiency of its production.

Summary Table:

| Key Feature | Description |

|---|---|

| Process | Uses mechanical pressure (screw press) to squeeze oil from seeds/nuts |

| Temperature | Keeps oil below 120°F (49°C) to protect heat-sensitive nutrients |

| Oil Quality | Preserves natural flavor, aroma, vitamins, and antioxidants |

| Yield vs. Quality | Lower yield than industrial methods, but higher quality oil |

| Chemical-Free | No solvents used; purely mechanical extraction |

Ready to produce high-quality, nutrient-rich oils in your lab or facility?

KINTEK specializes in lab equipment and consumables, offering reliable cold press oil machines designed for precision and efficiency. Whether you're in food science, research, or small-scale production, our solutions help you maintain the highest standards of oil integrity.

Contact us today to find the perfect cold press solution for your laboratory needs!

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- How strong is a hydraulic press? Unleash Immense Force with Pascal's Law

- Why is a laboratory hydraulic press necessary for bio-electrochemical sensor electrodes? Enhance Signal Sensitivity

- What are the disadvantages of KBr pellets? Avoid Moisture & Prep Errors in FTIR Analysis

- How do a laboratory hydraulic press and alumina molds ensure ASSB integrity? Achieve Perfect Solid-State Densification

- What is the amount of sample required when making a KBr pellet? Achieve Perfect IR Spectra with the 100:1 Ratio

- What is KBr pellet used in the examination of? Mastering FTIR Spectroscopy for Solid Samples

- How much force does a hydraulic press use? From 1 to 50,000 Tons of Controlled Power

- Why use a laboratory hydraulic press for fertilizer and glass pellets? Achieve Precise Chemical Analysis Results