At its core, a sputtering system works by physically ejecting atoms from a source material (the "target") using high-energy ion bombardment inside a vacuum. These ejected atoms then travel and deposit onto a substrate, such as a silicon wafer, forming an exceptionally uniform and dense thin film. It is a physical vapor deposition (PVD) method, fundamentally relying on momentum transfer, like a microscopic game of billiards.

The challenge of depositing materials with very high melting points or complex alloy compositions cannot be easily solved by simple evaporation. Sputtering overcomes this by using physical force—energetic ion impact—to dislodge atoms, making it a highly controlled and versatile technique for engineering advanced thin films.

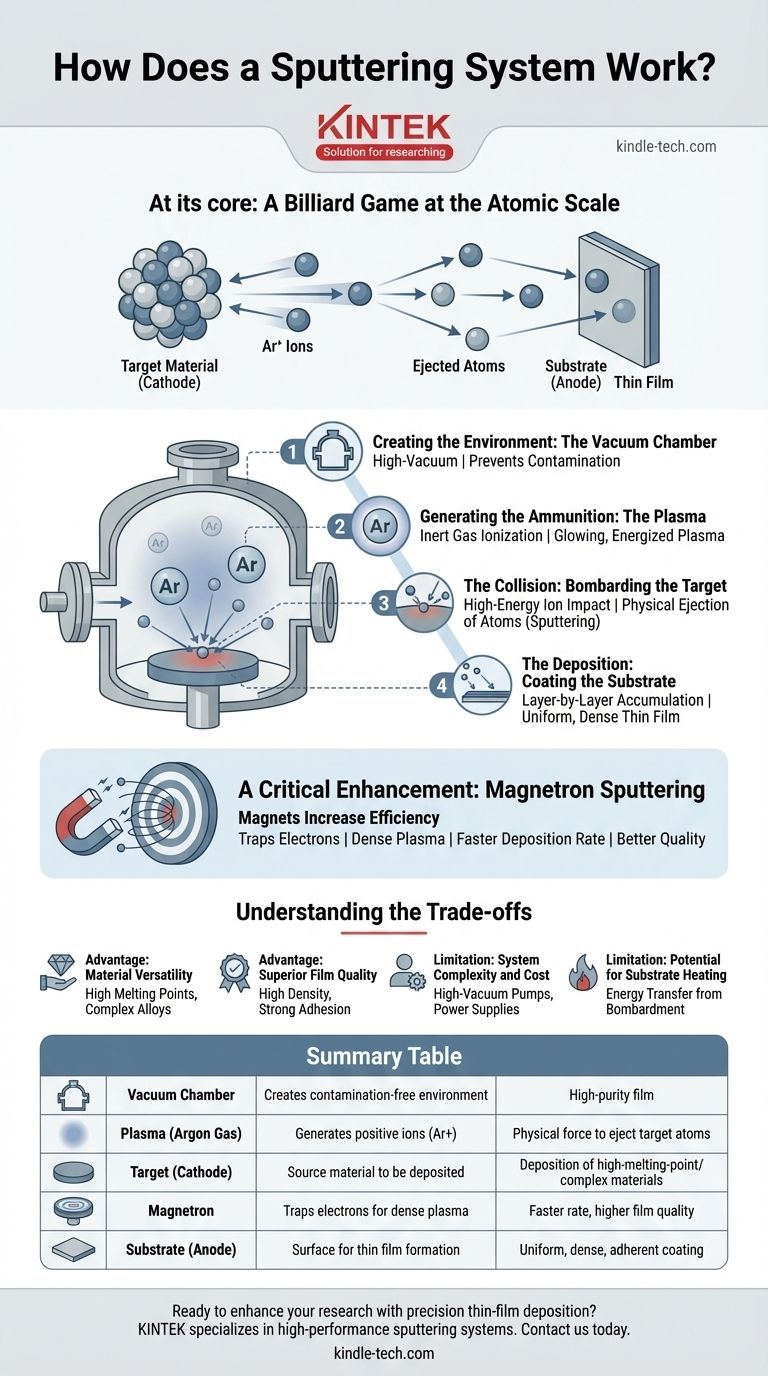

The Core Principle: A Billiard Game at the Atomic Scale

Sputtering is best understood as a sequence of physical events occurring within a highly controlled environment. Each step is critical to the quality and consistency of the final film.

Creating the Environment: The Vacuum Chamber

All sputtering takes place inside a sealed vacuum chamber. The initial atmosphere is pumped out to create a high-vacuum environment, which serves two primary purposes: preventing contamination of the film by atmospheric gases and increasing the "mean free path" of atoms, allowing them to travel from the target to the substrate without colliding with other particles.

Generating the Ammunition: The Plasma

Once a vacuum is established, an inert gas, typically Argon (Ar), is introduced into the chamber at a very low pressure. A high voltage is then applied, which strips electrons from the argon atoms. This process, called ionization, creates a plasma—a glowing, energized state of matter consisting of positive argon ions (Ar+) and free electrons.

The Collision: Bombarding the Target

The source material to be deposited is shaped into a plate called the target. This target is given a large negative electrical charge (acting as the cathode). The positively charged argon ions from the plasma are forcefully accelerated toward and collide with the negatively charged target surface.

If the energy of the impacting ion is high enough, it transfers its momentum to the target atoms, knocking them loose and ejecting them from the surface. This physical ejection process is sputtering.

The Deposition: Coating the Substrate

The ejected atoms from the target travel through the vacuum chamber and land on the substrate (which serves as the anode). As these atoms accumulate on the substrate's surface, they build up layer-by-layer to form a thin, solid film.

A Critical Enhancement: The Role of Magnetron Sputtering

While the basic process works, it is often slow. Modern systems almost universally use magnetron sputtering to dramatically increase the efficiency of the process.

How Magnets Increase Efficiency

In a magnetron system, strong magnets are placed behind the target. This magnetic field traps the light, fast-moving electrons from the plasma in a region close to the target surface.

These trapped electrons are forced to travel in a spiral path, greatly increasing their chances of colliding with and ionizing neutral argon gas atoms. This creates a very dense, stable plasma concentrated directly in front of the target where it is most needed.

The Benefits: Faster Rates and Better Films

The high-density plasma generated by the magnetron leads to a much higher rate of ion bombardment on the target. The direct result is a significantly faster deposition rate. Furthermore, it allows the system to sustain the plasma at lower gas pressures, which improves the quality and purity of the deposited film.

Understanding the Trade-offs

Sputtering is a powerful technique, but its advantages come with specific limitations. Understanding these trade-offs is key to determining if it is the right process for a given application.

Advantage: Material Versatility

Because sputtering is a physical and not a chemical or thermal process, it can be used to deposit almost any material. It excels at depositing elements with extremely high melting points (like tungsten or tantalum) and, crucially, complex alloys, as the sputtered material retains the composition of the target.

Advantage: Superior Film Quality

Sputtered films are known for their high density, strong adhesion to the substrate, and excellent uniformity over large areas. The kinetic energy of the arriving atoms helps to form a more robust and compact film structure compared to other methods like thermal evaporation.

Limitation: System Complexity and Cost

Sputtering systems are mechanically complex. They require high-vacuum pumps, precise gas flow controllers, high-voltage power supplies, and often, cooling systems for the target. This makes the initial equipment investment significantly higher than for simpler deposition methods.

Limitation: Potential for Substrate Heating

While more controlled than evaporation, the constant bombardment of particles can still transfer a significant amount of energy to the substrate, causing it to heat up. For heat-sensitive substrates, this can be a critical factor that requires careful management.

Making the Right Choice for Your Application

Selecting a deposition method depends entirely on the material properties and quality you need to achieve.

- If your primary focus is depositing complex alloys or refractory metals: Sputtering is the superior choice because its physical mechanism preserves the material's composition regardless of its melting point.

- If your primary focus is achieving high-purity, dense films with strong adhesion: The momentum transfer inherent in sputtering provides excellent film quality and adhesion that is difficult to match with other PVD techniques.

- If your primary focus is high-speed, low-cost deposition of simple metals: A simpler method like thermal evaporation may be a more cost-effective and faster alternative for non-critical applications.

Ultimately, sputtering is the industry-standard tool for applications demanding precision, versatility, and high-quality material properties at the nanoscale.

Summary Table:

| Key Component | Primary Function | Benefit |

|---|---|---|

| Vacuum Chamber | Creates a contamination-free environment with long atom travel paths. | Ensures high-purity film deposition. |

| Plasma (Argon Gas) | Generates positive ions (Ar+) that bombard the target. | Provides the physical force to eject target atoms. |

| Target (Cathode) | The source material (metal, alloy) to be deposited. | Allows deposition of high-melting-point materials and complex alloys. |

| Magnetron | Traps electrons to create a dense plasma near the target. | Dramatically increases deposition rate and film quality. |

| Substrate (Anode) | The surface (e.g., silicon wafer) where the thin film forms. | Results in a uniform, dense, and strongly adherent coating. |

Ready to enhance your research with precision thin-film deposition?

KINTEK specializes in high-performance sputtering systems and lab equipment, providing the tools you need to deposit everything from complex alloys to refractory metals with exceptional uniformity and adhesion. Our solutions are designed to meet the rigorous demands of modern laboratories.

Contact us today to discuss how our sputtering technology can advance your projects.

Get in Touch

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition