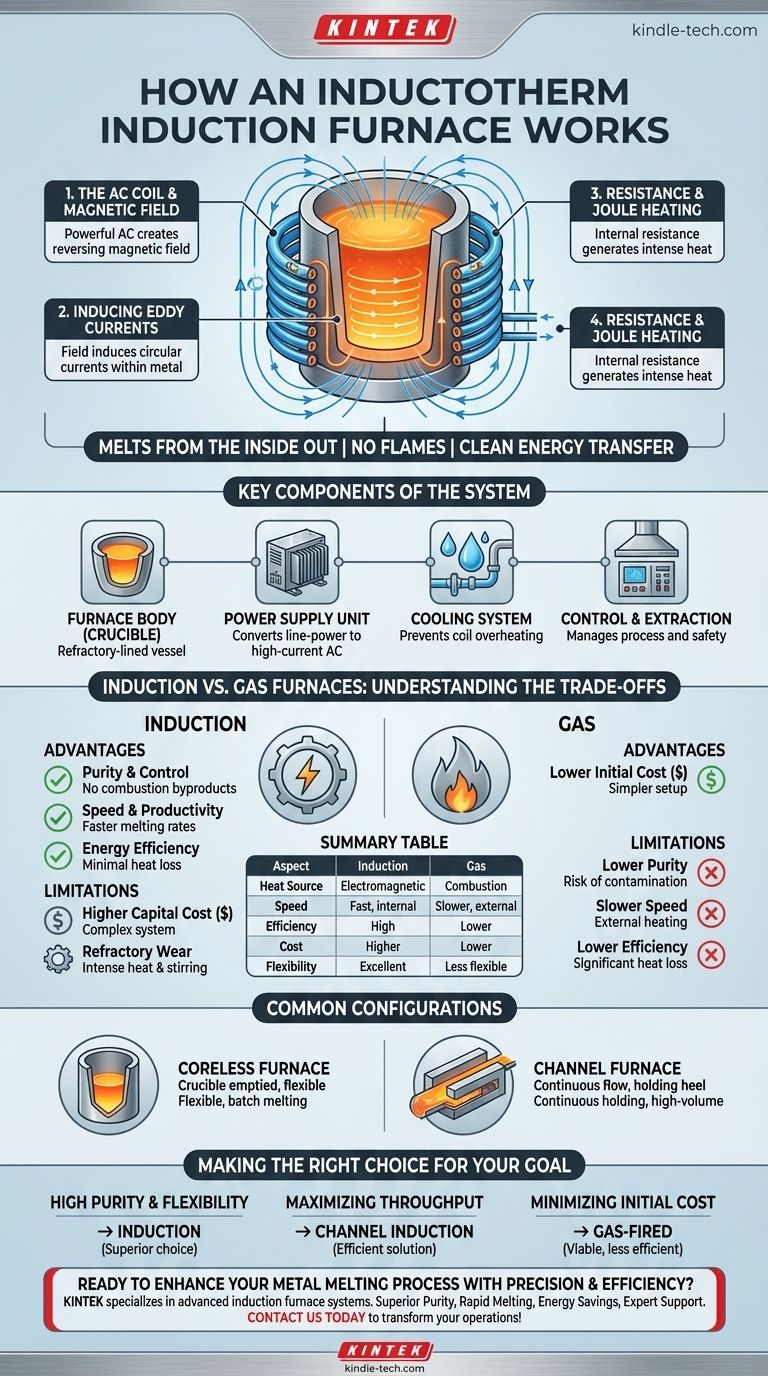

At its core, an Inductotherm induction furnace operates without flames or external heating elements. It uses the principle of electromagnetic induction to generate intense heat directly within the metal itself. A powerful alternating current (AC) flows through a copper coil, creating a strong, rapidly changing magnetic field that penetrates the metal charge, inducing internal electrical currents that cause it to melt from the inside out.

The fundamental advantage of induction heating is not just how it melts metal, but what it represents: a shift from imprecise, fuel-based combustion to clean, controllable, and highly efficient electromagnetic energy transfer.

The Core Principle: Electromagnetic Induction Heating

The process can be broken down into three distinct physical phenomena working in sequence.

The AC Coil and the Magnetic Field

An induction furnace's primary component is a large, water-cooled copper coil. A specialized power supply sends a high-power alternating current through this coil, generating a powerful and constantly reversing magnetic field in the space within and around it.

Inducing Eddy Currents in the Metal

When conductive material, such as scrap metal or ingot, is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents. This process is analogous to how a wireless charger induces a current in your phone's battery, but on a massive industrial scale.

Resistance and Joule Heating

All metals have a natural resistance to the flow of electricity. As the induced eddy currents flow through the metal, this resistance causes immense friction and generates heat, a principle known as Joule heating (or I²R loss). This heat is generated inside the metal, leading to rapid, uniform, and highly efficient melting. The magnetic forces also create a natural stirring action, ensuring a homogenous mixture.

Key Components of an Induction Furnace System

A modern induction furnace is a complex system with several critical integrated parts.

The Furnace Body (Crucible)

This is the refractory-lined vessel that contains the molten metal. The choice of refractory material is critical, as it must withstand extreme temperatures, chemical reactions with the melt, and the physical force of the magnetic stirring.

The Power Supply Unit

Often called the "brains" of the system, the power supply consists of a transformer, an inverter, and a bank of capacitors. It converts line-power electricity into the specific high-current, controlled-frequency AC needed to drive the induction coil efficiently.

The Cooling System

The immense electrical currents flowing through the coil generate their own heat. A robust water-cooling system is essential to prevent the copper coil itself from overheating and melting, which would destroy the furnace.

Control and Fume Extraction

Modern furnaces include sophisticated process control systems to manage melt temperature, power input, and safety parameters. A fume and dust extraction system is also vital for operator safety and environmental compliance.

Understanding the Trade-offs: Induction vs. Gas Furnaces

While highly effective, induction technology is not the only option. Understanding its advantages and limitations compared to traditional gas-fired furnaces is key to making an informed decision.

Advantage: Purity and Control

Because no fuel is burned, there are no byproducts of combustion (like carbon or sulfur) to contaminate the metal. This makes induction ideal for producing high-purity alloys where precise chemical composition is non-negotiable.

Advantage: Speed and Productivity

Induction heating is significantly faster than combustion methods. This speed directly translates to higher production rates, allowing foundries to increase throughput and fulfill orders more quickly.

Advantage: Energy Efficiency

Energy is transferred directly into the melt with minimal waste heat escaping into the surrounding environment. This is unlike gas furnaces, where a significant amount of energy is lost up the exhaust flue, making induction a more energy-efficient and environmentally friendly choice.

Limitation: Higher Capital Cost

Induction furnace systems, with their complex power supplies and cooling infrastructure, typically have a higher initial purchase and installation cost compared to simpler gas-fired furnaces.

Limitation: Refractory Wear

The intense, localized heat and the constant magnetic stirring action can cause faster wear on the refractory lining of the crucible compared to some other furnace types, requiring more frequent maintenance.

Common Furnace Configurations

Induction technology is versatile and can be deployed in several ways depending on the operational goal.

Coreless vs. Channel Furnaces

The coreless furnace, described above, is the most common type. It is highly flexible and can be completely emptied after each melt. A channel furnace maintains a constant "heel" or "swamp" of molten metal and is better suited for holding large quantities of a single alloy at temperature rather than for frequent melting of different materials.

Loading and Operational Styles

Furnaces can be designed in various physical forms, including top-loading designs where material is charged through the top. They can be operated in batches, where one complete melt is processed at a time, or in continuous operations where material is constantly fed through heated zones for high-volume production.

Making the Right Choice for Your Goal

The optimal melting technology depends entirely on your specific production requirements.

- If your primary focus is high-purity alloys and operational flexibility: Induction is the superior choice for its clean melting, precise temperature control, and ability to handle diverse and frequent batch changes.

- If your primary focus is maximizing throughput for a single alloy: A large channel induction furnace designed for holding, or a continuous induction system, may be the most efficient solution.

- If your primary focus is minimizing initial capital investment for general-purpose melting: A traditional gas-fired furnace remains a viable, though less efficient and controllable, alternative.

Understanding these fundamental principles empowers you to select the technology that best aligns with your operational and financial objectives.

Summary Table:

| Aspect | Induction Furnace | Traditional Gas Furnace |

|---|---|---|

| Heat Source | Electromagnetic induction | Fuel combustion |

| Melting Speed | Fast, direct internal heating | Slower, external heating |

| Metal Purity | High (no combustion byproducts) | Lower (risk of contamination) |

| Energy Efficiency | High (minimal heat loss) | Lower (significant heat loss) |

| Initial Cost | Higher capital investment | Lower initial cost |

| Operational Flexibility | Excellent for diverse alloys | Less flexible for frequent changes |

Ready to enhance your metal melting process with precision and efficiency?

KINTEK specializes in advanced lab equipment and consumables, including induction furnace systems tailored to your laboratory or foundry needs. Our solutions deliver:

- Superior Metal Purity: Achieve contamination-free melts for high-quality alloys.

- Rapid Melting & High Throughput: Boost productivity with faster, more efficient heating.

- Energy Savings: Reduce operational costs with highly efficient electromagnetic technology.

- Expert Support: From selection to installation, we ensure your system meets your goals.

Contact us today via our contact form to discuss how an induction furnace can transform your operations!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System