At its core, annealing is a controlled heat treatment process that alters a material's internal microstructure to achieve more desirable properties. It generally involves heating a material to a specific temperature, holding it there, and then cooling it slowly. This "resets" the material, primarily making it softer, more ductile, and easier to work with by relieving internal stresses and reducing defects.

While often perceived simply as a method for "softening" a material, annealing is more accurately a controlled structural reset. The true goal is to relieve internal stresses and refine the crystalline structure, which in turn improves properties like ductility, machinability, and electrical conductivity.

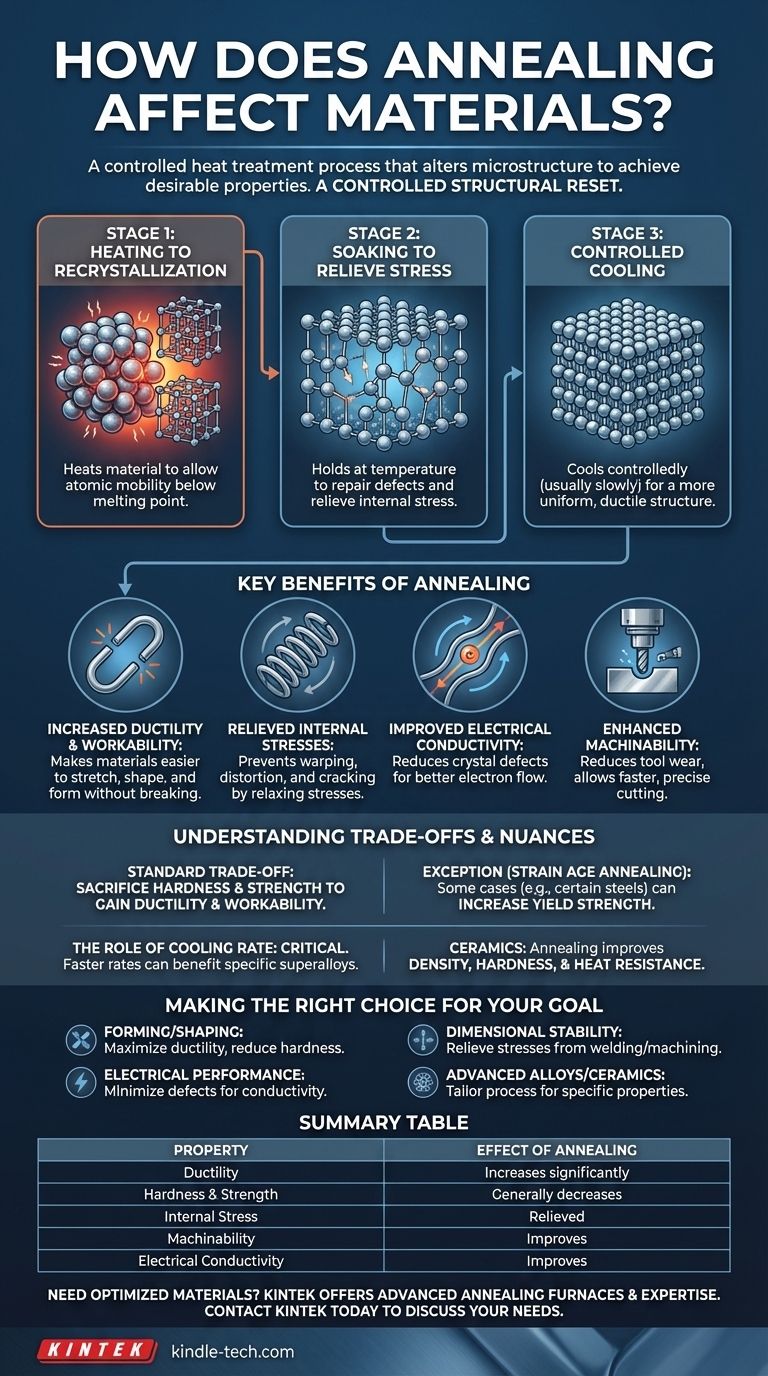

The Core Mechanism: Reorganizing the Microstructure

Annealing isn't a single action but a three-stage process. The outcome is determined by precise control over temperature, time, and cooling rate, which directly manipulate the material's atomic arrangement.

Stage 1: Heating to Recrystallization

The material is heated to a specific annealing temperature. This temperature is high enough to allow the atoms in the crystal lattice to become mobile but remains below the material's melting point.

Stage 2: Soaking to Relieve Stress

The material is held at this elevated temperature for a set period. During this "soaking" phase, the mobile atoms migrate, effectively repairing defects like dislocations within the crystal structure and relieving internal stresses introduced by prior work (like bending or machining).

Stage 3: Controlled Cooling for Desired Properties

The material is then cooled in a controlled manner. For most metals like steel, copper, and brass, a slow cooling rate is critical. This allows a new, more uniform, and less stressed crystalline structure to form, resulting in a more ductile and softer material.

Key Benefits of Annealing

By refining the microstructure, annealing produces several significant and practical benefits across different applications.

Increased Ductility and Workability

The primary benefit of annealing is a significant increase in ductility—the ability to be stretched or shaped without breaking. By reducing hardness and internal stress, it makes materials far more workable for processes like stamping, drawing, and forming.

Relieved Internal Stresses

Processes like welding, casting, and cold working introduce immense stress into a material's structure. If left unaddressed, this stress can cause warping, distortion, or even cracking over time. Annealing provides a way to relax these stresses, ensuring dimensional stability.

Improved Electrical Conductivity

Defects and dislocations in a material's crystal lattice impede the flow of electrons. By reducing the number of these dislocations, annealing creates a clearer path, which can result in better electrical conductivity.

Enhanced Machinability

A softer, more uniform, and less brittle material is significantly easier to machine. Annealing improves machinability by reducing tool wear and allowing for faster and more precise cutting operations.

Understanding the Trade-offs and Nuances

While the general principles of annealing are straightforward, the specific outcomes are highly dependent on the material and process parameters.

The Standard Trade-off: Hardness for Ductility

For most common metals, the primary trade-off is clear: you sacrifice hardness and tensile strength to gain ductility and workability. This is a deliberate choice made to prepare the material for subsequent manufacturing steps.

The Exception: Strain Age Annealing

In some specific cases, a low-temperature anneal can actually increase yield strength. For example, in certain steels, a carefully controlled process allows carbon atoms to migrate and pin dislocations in place. This "Cottrell atmosphere" effect makes the material stronger but also reduces its elongation (ductility).

The Critical Role of Cooling Rate

While slow cooling is the standard, it is not a universal rule. For some advanced materials, like the superalloy Inco X-750, a faster cooling rate can actually produce a lower hardness, making it easier to work with in subsequent operations. This highlights that the process must be tailored to the specific alloy.

Annealing Beyond Metals: The Case for Ceramics

Annealing is also a critical process for ceramics, but the effects can be different. It is used to improve the density, hardness, and heat resistance of ceramic products. The process stabilizes the material and any surface coatings, making the final product stronger, more reliable, and of higher quality.

Making the Right Choice for Your Goal

Annealing is not a one-size-fits-all solution but a versatile tool for material preparation. Your specific goal will dictate how and why you should apply it.

- If your primary focus is preparing a material for forming or shaping: Use a standard annealing process to significantly increase ductility and reduce hardness, making the material far less prone to cracking.

- If your primary focus is optimizing electrical performance: Anneal the material to reduce crystal defects and dislocations, thereby improving its electrical conductivity.

- If your primary focus is ensuring dimensional stability after machining or welding: Apply an annealing cycle specifically to relieve internal stresses that could otherwise lead to warping or premature failure.

- If your primary focus is working with advanced alloys or ceramics: Recognize that annealing's effects are highly specific; it may increase hardness in ceramics or require precise cooling rates for certain superalloys.

Ultimately, understanding annealing empowers you to precisely control a material's properties to meet the demands of your specific application.

Summary Table:

| Key Property Change | Effect of Annealing |

|---|---|

| Ductility | Increases significantly |

| Hardness & Strength | Generally decreases |

| Internal Stress | Relieved |

| Machinability | Improves |

| Electrical Conductivity | Improves |

Need to optimize material properties for your lab or production process?

Annealing is a precise science. The right equipment is critical for achieving consistent, reliable results. KINTEK specializes in lab equipment and consumables, including advanced annealing furnaces designed for exact temperature control and uniform heating.

We help our customers in research and manufacturing:

- Improve material workability and performance

- Ensure dimensional stability of critical components

- Enhance the quality and reliability of your final products

Let our experts help you select the perfect annealing solution for your specific materials and goals. Contact KINTEK today to discuss your needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What are the three most important factors in material heat treatment? Master Temperature, Time, and Cooling for Superior Properties

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What are the challenges of welding stainless steel? Overcome Warping, Sensitization, and Contamination

- What is sputtering technology? A Guide to Precision Thin Film Deposition