Fundamentally, heat treatment is not a process you apply to a material; it is a design parameter that dictates the material you must select. The choice of material is governed by its chemical composition, which determines its ability to undergo specific microstructural changes—known as phase transformations—when subjected to thermal cycles. Without the right constituent elements, a material simply will not respond to heat treatment in a predictable or useful way.

The core principle is this: You select a material based on its inherent capability to be transformed by heat to achieve your target mechanical properties. The material's chemistry, particularly its alloy content, determines the specific heat treatment processes it can undergo and the final balance of hardness, strength, and toughness it can attain.

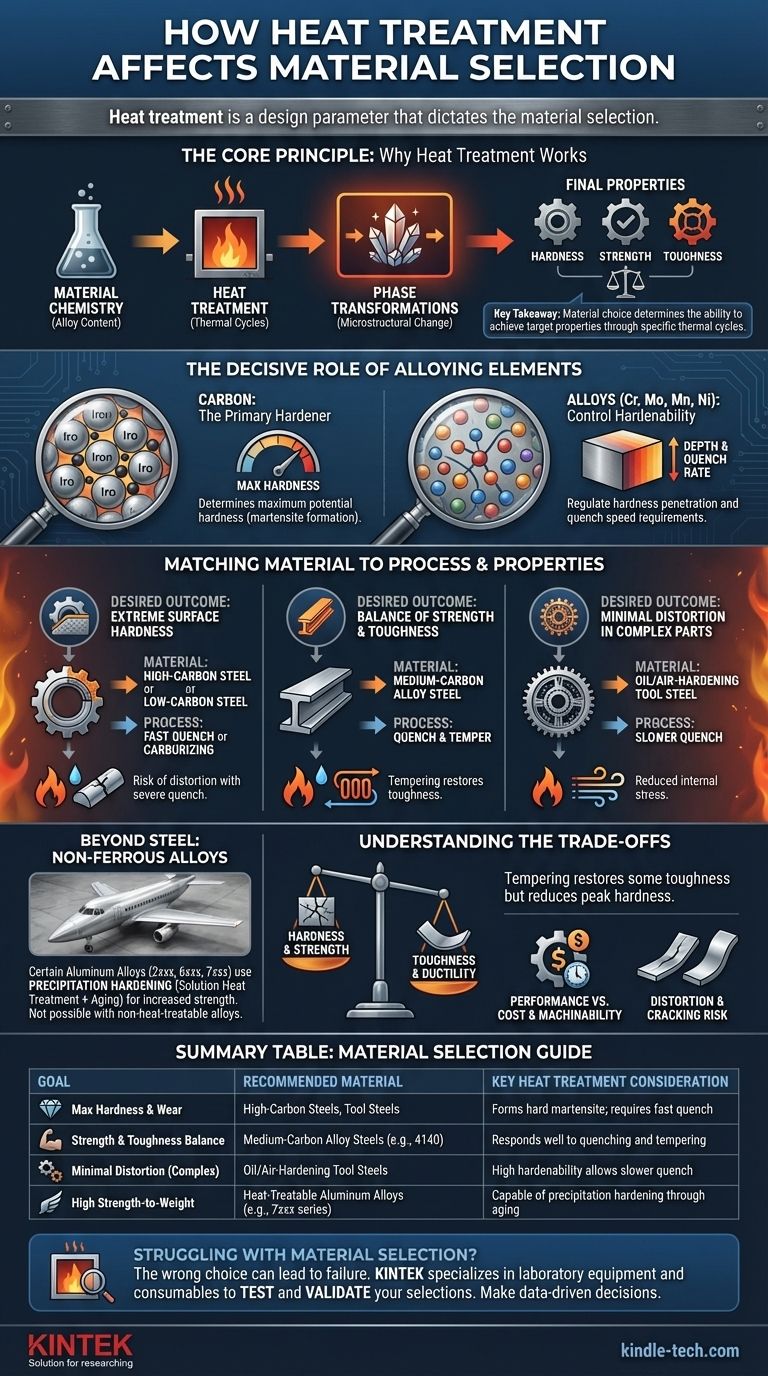

The Core Principle: Why Heat Treatment Works

To select the right material, you must first understand the mechanism that makes heat treatment effective. It's not magic; it's a controlled manipulation of the material's internal crystal structure.

Phase Transformations: The Engine of Change

Most heat treatments, especially in steels, rely on a process of phase transformation. Heating the steel above a critical temperature changes its crystal structure into a phase called austenite, which has a high capacity for dissolving carbon.

Upon cooling (quenching), this structure transforms again. A very rapid quench traps the carbon and forms martensite, an extremely hard and brittle phase. Slower cooling rates produce softer, more ductile structures like pearlite or bainite. The material you choose must be capable of forming austenite in the first place.

The Decisive Role of Alloying Elements

The specific elements within an alloy are the "levers" that control how it responds to heat treatment.

In steel, carbon is the primary element that determines the maximum potential hardness. More carbon allows for the formation of a harder martensitic structure. A low-carbon steel simply cannot be hardened significantly through quenching, regardless of the process.

Other elements like chromium, molybdenum, manganese, and nickel control hardenability. This is a measure of how deeply the hardness can penetrate into the material from the surface and how slow of a quench is needed to achieve full hardness.

Matching Material to Process and Properties

Your desired outcome directly informs your material choice. You cannot select a material in a vacuum without considering the heat treatment process and the final properties required.

Hardenability Dictates the Quench

A plain carbon steel with low hardenability requires an extremely fast and severe quench (e.g., in water or brine) to become hard. This induces immense internal stress and carries a high risk of distortion or cracking, making it unsuitable for complex shapes.

In contrast, an alloy steel with high hardenability can be hardened with a much slower quench (e.g., in oil or even still air for "air-hardening" steels). This drastically reduces the risk of distortion, making these alloys essential for intricate parts, tools, and dies.

Carbon Content Defines Hardness and Use Case

If your goal is a component with extreme surface hardness for wear resistance, you must select a high-carbon steel (e.g., >0.60% carbon) or a low-carbon steel that will undergo a surface-hardening process like carburizing.

If your goal is a structural component requiring good toughness and strength, you would select a medium-carbon steel (e.g., 0.30%-0.50% carbon) that can be quenched and then tempered to achieve a good balance of properties.

Beyond Steel: Non-Ferrous Alloys

This principle also applies to non-ferrous metals. Certain aluminum alloys (like the 2xxx, 6xxx, and 7xxx series) are selected specifically because they can be "precipitation hardened." This involves a solution heat treatment followed by aging to form fine precipitates within the metal's crystal structure, significantly increasing its strength. You cannot achieve this with a non-heat-treatable alloy like the 5xxx series.

Understanding the Trade-offs

Material selection for heat treatment is always a balance of competing factors. Recognizing these trade-offs is the mark of an experienced designer.

Hardness vs. Toughness

This is the most fundamental trade-off. As a material's hardness and strength increase through heat treatment, its toughness (resistance to fracture) and ductility decrease. The material becomes more brittle.

The process of tempering—reheating a quenched part to a lower temperature—is used to restore some toughness, but this comes at the cost of reducing some of the peak hardness. The alloy content of your material determines the starting point and the range of this trade-off.

Performance vs. Cost and Machinability

Highly alloyed materials with excellent hardenability and performance at high temperatures are significantly more expensive than plain carbon steels.

Furthermore, these alloys are often more difficult to machine in their initial (annealed) state. This adds manufacturing time and cost, a critical factor that must be weighed against the required in-service performance.

Distortion and Cracking Risk

As mentioned, the choice of material is your primary defense against distortion and cracking during quenching. Choosing a material with just enough hardenability for the part's cross-section—and no more—is a key engineering decision. Using an air-hardening tool steel for a complex gear is a deliberate choice to mitigate the risk of warping that would be unavoidable with a water-hardening steel.

Making the Right Material Choice

Your selection should be guided by the primary performance driver for your component.

- If your primary focus is maximum hardness and wear resistance: Select high-carbon steels or specialized tool steels designed for this purpose.

- If your primary focus is a balance of strength and toughness for structural parts: Select medium-carbon alloy steels (like 4140 or 4340) that respond well to quenching and tempering.

- If your primary focus is minimizing distortion in complex geometries: Select an oil-hardening or air-hardening tool steel with high alloy content.

- If your primary focus is strength-to-weight ratio: Select a heat-treatable aluminum alloy from the 2xxx, 6xxx, or 7xxx series.

Ultimately, selecting the right material is the first and most critical step in successfully designing a heat-treated component.

Summary Table:

| Material Selection Goal | Recommended Material Type | Key Heat Treatment Consideration |

|---|---|---|

| Maximum Hardness & Wear Resistance | High-Carbon Steels, Tool Steels | Capable of forming hard martensite; requires fast quench |

| Balance of Strength & Toughness | Medium-Carbon Alloy Steels (e.g., 4140) | Responds well to quenching and tempering for property balance |

| Minimal Distortion in Complex Parts | Oil/Air-Hardening Tool Steels | High hardenability allows slower quench, reducing stress |

| High Strength-to-Weight Ratio | Heat-Treatable Aluminum Alloys (e.g., 7xxx series) | Capable of precipitation hardening through aging |

Struggling to select the right material for your heat treatment process? The wrong choice can lead to failed parts, excessive distortion, or inadequate performance. KINTEK specializes in providing the laboratory equipment and consumables you need to test and validate your material selections. From furnaces for precise thermal cycles to analysis tools for verifying microstructure, we help you make data-driven decisions. Contact our experts today via our contact form to ensure your next project achieves its target properties and performance.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance