At its core, metal laser sintering is an additive manufacturing process that builds three-dimensional metal parts from a digital file. It uses a high-power laser to selectively fuse or melt fine metallic powder, layer by meticulous layer, inside a controlled chamber. This method is also commonly known by more specific terms like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM).

The true innovation of metal laser sintering is not just melting powder; it's the ability to construct incredibly complex, fully dense metal components directly from a digital design, achieving geometries that are impossible for traditional machining to replicate.

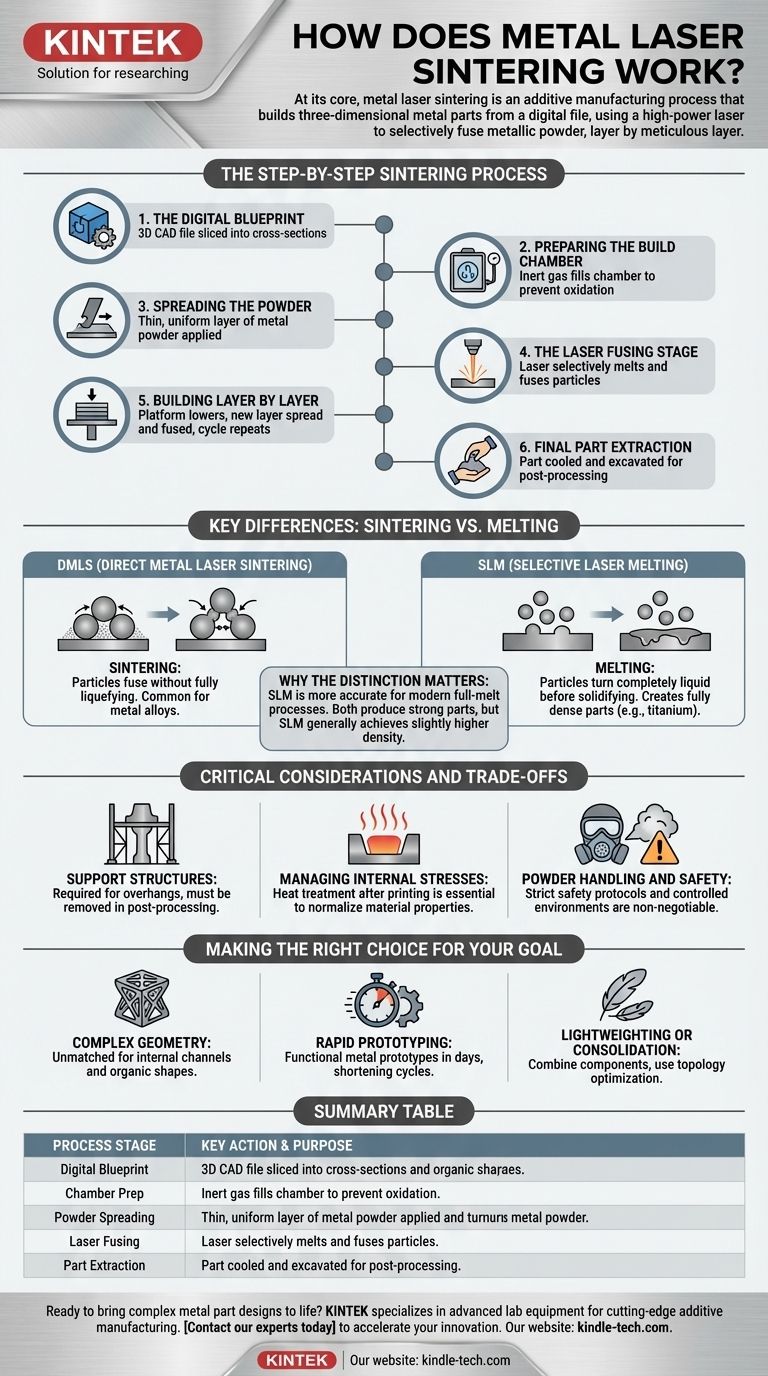

The Step-by-Step Sintering Process

Understanding the workflow reveals the precision and control inherent in this technology. Each stage is critical to producing a successful final part.

The Digital Blueprint

The process begins with a 3D computer-aided design (CAD) file. This digital model is then "sliced" by specialized software into hundreds or thousands of thin, two-dimensional cross-sections, creating a precise instruction set for the machine.

Preparing the Build Chamber

The build area is sealed and flooded with an inert gas, typically argon or nitrogen. This controlled atmosphere is crucial as it displaces oxygen, preventing the fine metal powder from oxidizing or combusting at the high temperatures required for fusion.

Spreading the Powder

A recoater blade or roller moves across the build platform, depositing an extremely thin and uniform layer of the chosen metal powder, often just 20 to 60 microns thick.

The Laser Fusing Stage

A high-power fiber laser, guided by the sliced CAD file, scans the surface of the powder bed. The intense energy of the laser selectively melts and fuses the powder particles together, solidifying the first cross-section of the part.

Building Layer by Layer

Once a layer is complete, the build platform lowers by the exact thickness of a single layer. The recoater blade applies a fresh coat of powder, and the laser fuses the next cross-section, bonding it to the one below. This cycle repeats thousands of times until the part is fully formed.

Final Part Extraction

After the build is complete, the part is left to cool within the machine. It is then carefully excavated from the surrounding loose powder, which can often be sieved and reused. The part, still attached to the build plate, then moves to post-processing.

Key Differences: Sintering vs. Melting

While often used interchangeably, the technical terms reveal a subtle but important distinction in the physics of the process. Understanding this helps clarify the capabilities and material outcomes.

DMLS (Direct Metal Laser Sintering)

Technically, sintering involves heating the powder to a point where the particles fuse together at their surfaces without fully liquefying. This process is common for parts made from metal alloys.

SLM (Selective Laser Melting)

SLM uses a higher laser power to achieve a full melt, meaning the powder particles turn completely liquid before solidifying. This creates a fully dense, homogenous part and is typically used for pure materials like titanium or aluminum.

Why the Distinction Matters

In practice, most modern machines achieve a full melt, making SLM the more physically accurate term. However, DMLS is a widely recognized trade name. The key takeaway is that both processes produce strong, dense metal parts, with SLM generally achieving slightly higher density and strength.

Critical Considerations and Trade-offs

Metal laser sintering is a powerful tool, but it is not without its complexities. A successful outcome depends on anticipating and managing key challenges.

The Need for Support Structures

Just like in plastic 3D printing, any significant overhangs or steep angles require support structures. These supports are printed from the same material and anchor the part to the build plate, preventing distortion from thermal stress and giving the laser a surface to build upon. These supports must be mechanically removed in post-processing.

Managing Internal Stresses

The rapid heating and cooling cycles inherent in the process can build up internal stresses within the part. A heat treatment or stress-relieving cycle after printing is almost always required to normalize the material's microstructure and ensure its mechanical properties are stable.

Powder Handling and Safety

Working with fine, atomized metal powders requires strict safety protocols. These materials can be a respiratory hazard and, in some cases, combustible. Proper ventilation, protective equipment, and controlled environments are non-negotiable.

Making the Right Choice for Your Goal

Metal laser sintering is not a universal solution; it is a specialized process that excels when its unique strengths align with the engineering objective.

- If your primary focus is complex geometry: This technology is unmatched for creating parts with internal cooling channels, latticed structures, or organic shapes that are impossible to machine.

- If your primary focus is rapid prototyping: It allows for the creation of functional metal prototypes directly from a digital file in days, drastically shortening development cycles by eliminating the need for tooling.

- If your primary focus is lightweighting or consolidation: It enables engineers to combine multiple components into a single, complex part and use topology optimization to remove every gram of unnecessary material.

Ultimately, mastering metal laser sintering means understanding it as a complete manufacturing system, from digital design to final post-processing.

Summary Table:

| Process Stage | Key Action | Purpose |

|---|---|---|

| Digital Blueprint | 3D CAD model is sliced into layers | Creates instructions for the laser |

| Chamber Prep | Chamber is filled with inert gas (Argon/Nitrogen) | Prevents powder oxidation and combustion |

| Powder Spreading | Recoater blade spreads a thin layer of metal powder | Creates a fresh surface for fusing |

| Laser Fusing | High-power laser scans and fuses powder particles | Builds the part cross-section, layer by layer |

| Part Extraction | Part is excavated from loose powder and cooled | Prepares the part for post-processing |

Ready to bring complex metal part designs to life?

KINTEK specializes in providing the advanced lab equipment and consumables needed for cutting-edge additive manufacturing processes like metal laser sintering. Whether you are prototyping, researching, or scaling production, our solutions help you achieve precise, dense, and complex metal parts faster.

Contact our experts today to discuss how we can support your laboratory's specific needs and accelerate your innovation.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Double Plate Heating Press Mold for Lab

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What are the characteristics and applications of Vapour Phase Epitaxy (VPE)? Key Insights for Semiconductor Growth

- What is atomic layer deposition of metals? Achieve Atomic-Scale Precision for Your Thin Films

- What are the common precursors used in CVD reactions? A Guide to Hydrides, Halides, and Organometallics

- What is the MOCVD technique? The Key to Manufacturing High-Performance Semiconductors

- What are the methods for preparing graphene? Top-Down vs. Bottom-Up Synthesis Explained

- How are semiconductor thin films made? A Guide to Deposition Techniques for Electronics

- What are the by products of pyrolysis oil? Unlocking the Value of All Three Co-Products

- What is methane pyrolysis? A Low-Carbon Path to Hydrogen from Natural Gas