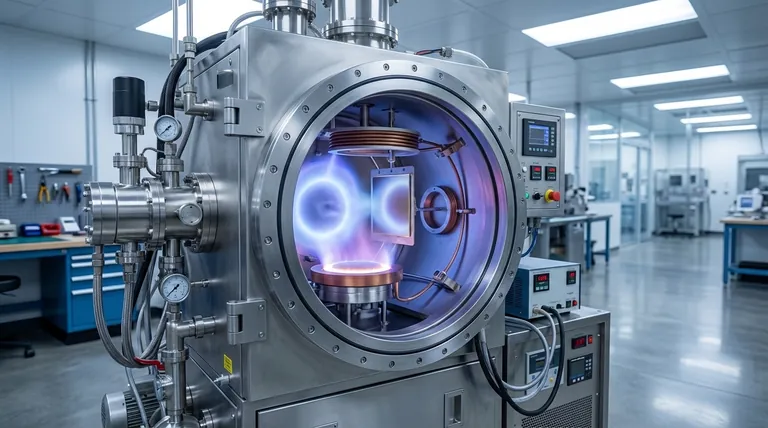

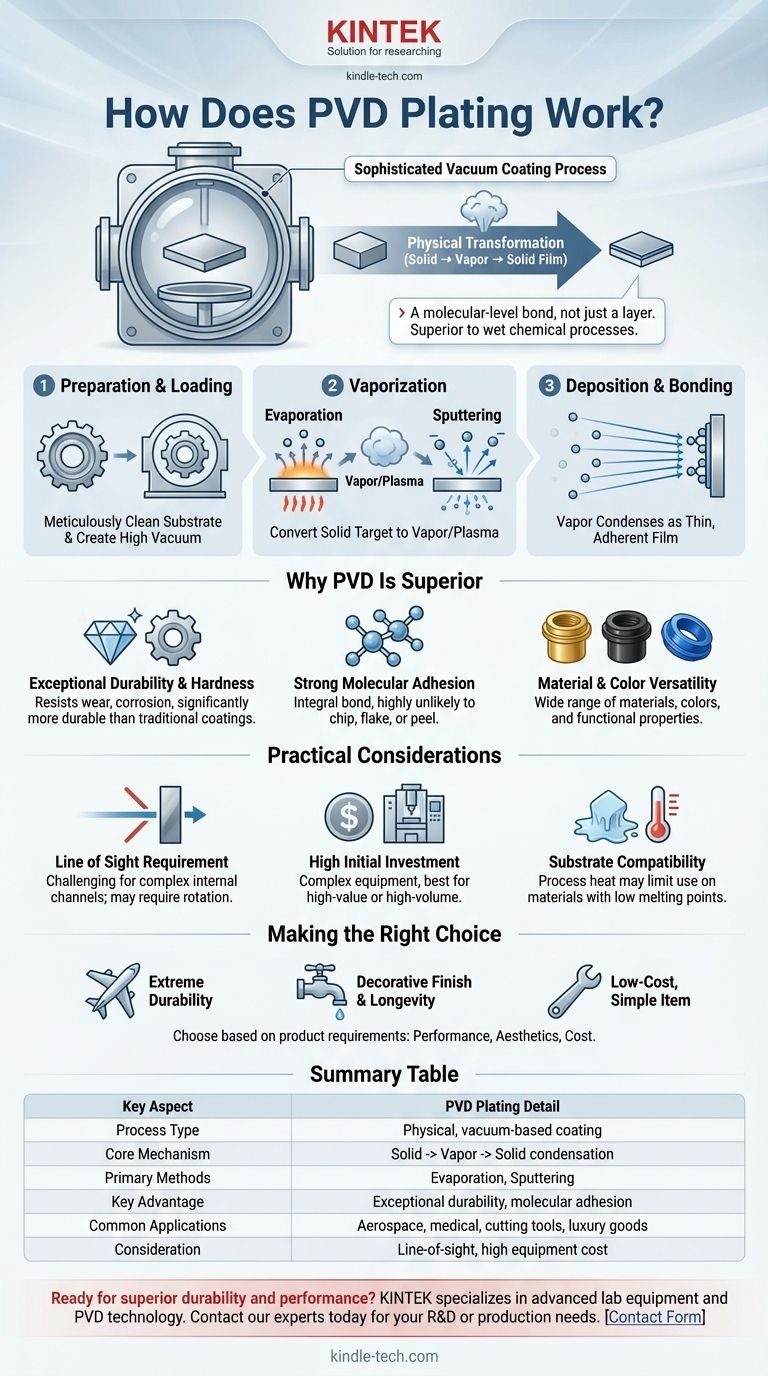

At its core, Physical Vapor Deposition (PVD) is a sophisticated vacuum coating process that bonds a thin film of material to an object's surface on a molecular level. It works by transforming a solid coating material into a vapor inside a vacuum chamber. This vapor then travels and condenses onto the object, forming a dense, durable, and highly adherent layer.

The critical insight is that PVD is not a wet chemical process like painting or electroplating. Instead, it's a physical transformation—solid to vapor, then back to a solid film—that creates a finish that is bonded to the substrate rather than simply layered on top.

The Three-Step PVD Process Explained

To truly understand how PVD works, it's best to break it down into its three fundamental stages. This entire sequence takes place within a sealed, high-vacuum chamber to ensure absolute purity and prevent contamination from airborne particles.

Step 1: Preparation and Loading into a Vacuum

Before the process begins, the item to be coated, known as the substrate, must be meticulously cleaned. Any surface imperfection or contaminant will compromise the final coating's adhesion and quality.

Once cleaned, the substrate is placed into the PVD chamber. All the air is then pumped out to create a near-perfect vacuum, an environment essential for the next steps.

Step 2: Vaporization of the Coating Material

This is the heart of the process. A solid, high-purity coating material, referred to as the target, is converted into a vapor. This is typically achieved in one of two ways:

- Evaporation: The target material is heated with an electrical arc or electron beam until it boils and evaporates, releasing atoms into the chamber.

- Sputtering: The target is bombarded with high-energy ions (often from an inert gas like argon). This acts like a microscopic sandblaster, knocking atoms loose from the target material and ejecting them into the vacuum.

In many cases, this vaporized material exists in an energized state known as plasma.

Step 3: Deposition and Bonding

The vaporized atoms of the coating material travel in a straight line through the vacuum chamber until they strike the substrate.

Upon contact, they condense back into a solid state, forming a thin, highly-uniform film. This layer builds up atom by atom, creating a powerful molecular bond with the substrate's surface.

Why PVD Is a Superior Finishing Method

The unique nature of the PVD process provides significant advantages over traditional coating methods, which explains its use in high-performance applications from aerospace to medical devices.

Exceptional Durability and Hardness

Because the coating is bonded at a molecular level, it is incredibly hard and resistant to wear and corrosion. A PVD finish is significantly more durable than most paints, powders, or electroplated coatings.

Strong Molecular Adhesion

The film becomes an integral part of the substrate's surface. This means it is highly unlikely to chip, flake, or peel, even under significant stress.

Material and Color Versatility

PVD can deposit a wide range of materials, including metals, alloys, and ceramics like titanium nitride. This versatility allows for a vast spectrum of colors, finishes, and functional properties, such as low friction or biocompatibility.

Understanding the Practical Considerations

While powerful, PVD is not the universal solution for every coating need. Its process characteristics create specific trade-offs that are important to recognize.

The Need for a Line of Sight

The coating material travels in a straight line from the target to the substrate. This "line-of-sight" nature means that coating complex internal channels or deep, recessed areas can be challenging without sophisticated machinery to rotate the parts during the process.

High Initial Investment

PVD equipment is complex and represents a significant capital investment. This makes the process better suited for high-value components or high-volume production where the cost can be amortized effectively.

Substrate Compatibility

While versatile, the PVD process often involves heat, which can limit its use on materials with very low melting points, such as certain plastics. The substrate must be able to withstand the conditions inside the vacuum chamber.

Making the Right Choice for Your Goal

Selecting a coating process depends entirely on your product's requirements for performance, aesthetics, and cost.

- If your primary focus is extreme durability and wear resistance: PVD is the superior choice for tools, medical implants, aerospace components, and luxury watches where performance is non-negotiable.

- If your primary focus is a decorative finish with high longevity: PVD provides vibrant, long-lasting colors for items like premium faucets, architectural hardware, and jewelry that will not easily tarnish, fade, or scratch.

- If your primary focus is coating a low-cost, simple item: Simpler methods like painting or traditional electroplating may be more cost-effective if the high performance of PVD is not required.

Ultimately, understanding the PVD process allows you to leverage its molecular-level bonding to create products with unparalleled durability and a superior finish.

Summary Table:

| Key Aspect | PVD Plating Detail |

|---|---|

| Process Type | Physical, vacuum-based coating (not chemical) |

| Core Mechanism | Solid target material is vaporized, then condenses on the substrate |

| Primary Methods | Evaporation, Sputtering |

| Key Advantage | Exceptional durability and molecular-level adhesion |

| Common Applications | Aerospace components, medical devices, cutting tools, luxury goods |

| Consideration | Line-of-sight process; high initial equipment investment |

Ready to achieve superior durability and performance for your components?

The PVD process is complex, but the results are unmatched. KINTEK specializes in advanced lab equipment and consumables for materials science and coating development. Whether you're in R&D or high-volume production, our expertise can help you leverage PVD technology to create products with exceptional wear resistance, corrosion protection, and vibrant, long-lasting finishes.

Contact our experts today to discuss how we can support your laboratory and coating needs. Let's find the right solution for your project.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing