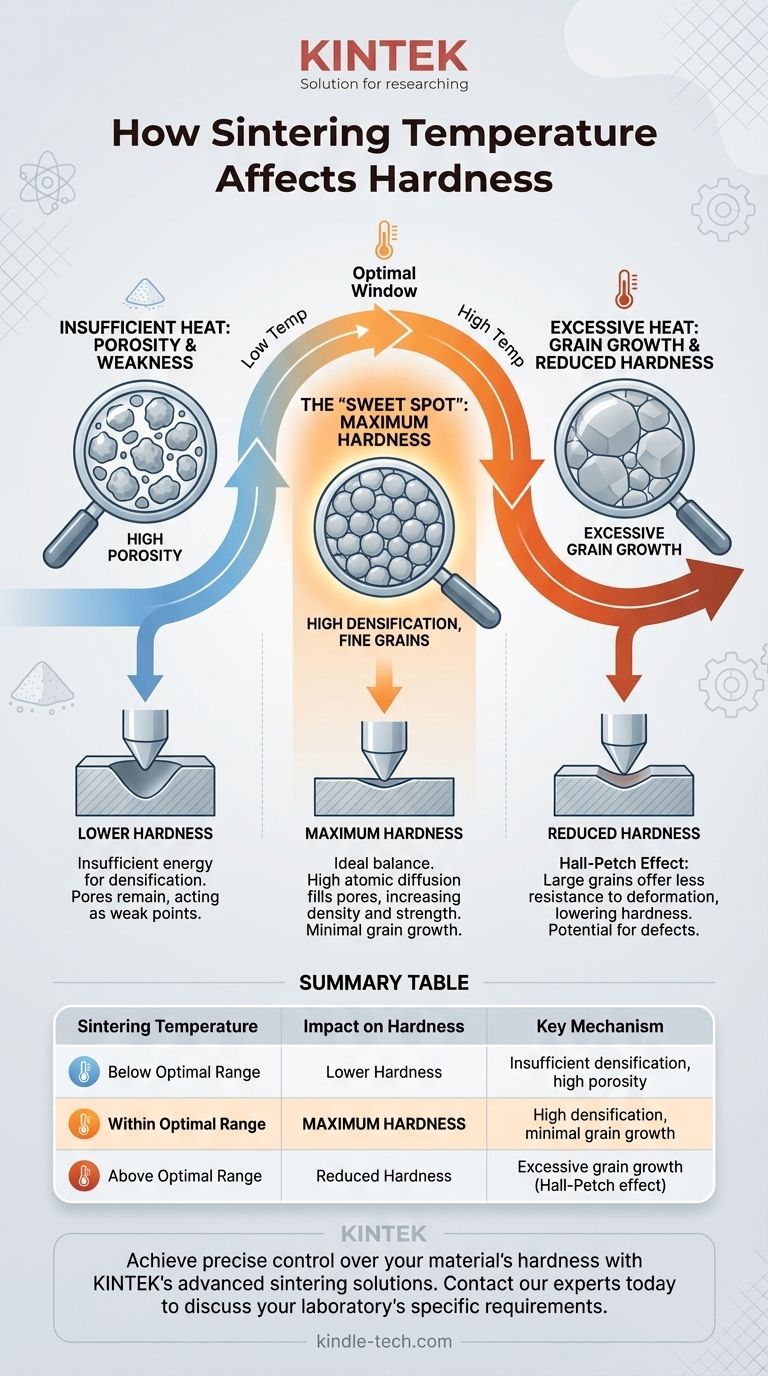

In material science, the relationship between sintering temperature and hardness is direct but nuanced. As sintering temperature increases, the hardness of the material generally increases due to enhanced particle bonding and densification. However, this trend holds only up to an optimal point, beyond which excessive temperatures can cause microstructural defects like grain growth, leading to a decrease in hardness.

The core principle is a trade-off: higher sintering temperatures provide the necessary energy to reduce porosity and increase density, which boosts hardness. But if the temperature becomes too high, it promotes grain coarsening, which weakens the material's microstructure and ultimately reduces hardness.

The Goal of Sintering: From Powder to Solid

Sintering is a thermal process for compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction. It transforms a loose powder compact into a dense, coherent body.

The Role of Pores

The initial powder compact is full of empty spaces, or pores. These pores are points of weakness. A material with high porosity is less dense and, consequently, has lower hardness and mechanical strength.

The Mechanism of Densification

The primary goal of sintering is densification—the elimination of these pores. Heat provides the thermal energy that allows atoms to move, or diffuse, across the boundaries of adjacent powder particles. This atomic movement fills the voids, shrinks the component, and bonds the particles into a strong, unified structure.

How Temperature Drives Hardness

Temperature is the primary lever for controlling the rate and extent of densification. Its effect on the final hardness is a direct result of its influence on the material's microstructure.

The Direct Link: Temperature, Density, and Hardness

As sintering temperature rises, the rate of atomic diffusion increases exponentially. This accelerates the closing of pores and increases the material's overall density.

Hardness is fundamentally a measure of a material's resistance to localized plastic deformation. A denser material, with fewer internal voids, offers greater resistance to indentation, and is therefore harder.

The Optimal Sintering Window

For any given material, there is an optimal temperature window. Within this range, you achieve maximum densification without introducing significant negative effects. Finding this "sweet spot" is critical for process control.

Understanding the Trade-offs: When More Heat Hurts

Simply applying more heat is not always better. Exceeding the optimal temperature introduces defects that can compromise or even reverse the gains in hardness.

The Problem of Grain Growth

At excessively high temperatures, the system's energy drives a process called grain growth or coarsening. Smaller grains, which have higher surface energy, are consumed by larger, growing grains. This results in a microstructure with a few very large grains instead of many fine ones.

The Hall-Petch Effect: Why Large Grains Reduce Hardness

The relationship between grain size and mechanical strength is well-defined by the Hall-Petch effect. This principle states that a material's strength and hardness decrease as its grain size increases.

The boundaries between grains act as barriers to dislocation movement (the primary mechanism of plastic deformation). A material with many fine grains has a greater total area of grain boundaries, making it more effective at resisting deformation and thus harder.

Other Risks of Excessive Temperature

Beyond grain growth, extreme temperatures can cause other problems like partial melting, component distortion (slumping), or the formation of undesirable chemical phases, all of which degrade the final mechanical properties.

Optimizing Sintering Temperature for Your Goal

The ideal temperature is not a universal constant but depends on your material system, processing equipment, and desired outcome.

- If your primary focus is maximum hardness: You must carefully balance densification and grain growth. This often involves finding the highest possible temperature that achieves near-full density before the onset of rapid grain coarsening.

- If your primary focus is process efficiency: A slightly higher temperature for a shorter time can achieve similar density as a lower temperature for a longer time. However, you must validate that this accelerated cycle does not push the material into the grain growth region.

- If you are developing a new process: Begin with a temperature range of 50% to 75% of the material's absolute melting point as a starting point. Conduct systematic experiments to map the relationship between temperature, density, grain size, and hardness.

Mastering the effect of sintering temperature is fundamental to engineering a material with predictable and reliable performance.

Summary Table:

| Sintering Temperature Effect | Impact on Hardness | Key Mechanism |

|---|---|---|

| Below Optimal Range | Lower Hardness | Insufficient densification, high porosity |

| Within Optimal Range | Maximum Hardness | High densification, minimal grain growth |

| Above Optimal Range | Reduced Hardness | Excessive grain growth (Hall-Petch effect) |

Achieve precise control over your material's hardness with KINTEK's advanced sintering solutions. Our lab equipment and consumables are designed to help you find the perfect sintering temperature window for maximum density and strength. Whether you're developing new materials or optimizing existing processes, KINTEK provides the reliable tools you need for consistent, high-performance results.

Contact our experts today to discuss how we can support your laboratory's specific sintering requirements!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- How do you clean an alumina tube furnace? Extend Tube Life with Proper Maintenance