In short, increasing the sintering temperature generally improves a material's mechanical properties, but only up to an optimal point. The heat provides the energy needed to bond material particles together, increasing density and creating a stronger, more cohesive final component. Exceeding the optimal temperature, however, can degrade these properties.

The relationship between sintering temperature and mechanical strength is fundamentally about controlling density. Temperature drives the atomic diffusion that eliminates pores between particles, but excessive heat can cause defects like oversized grains, ultimately weakening the material.

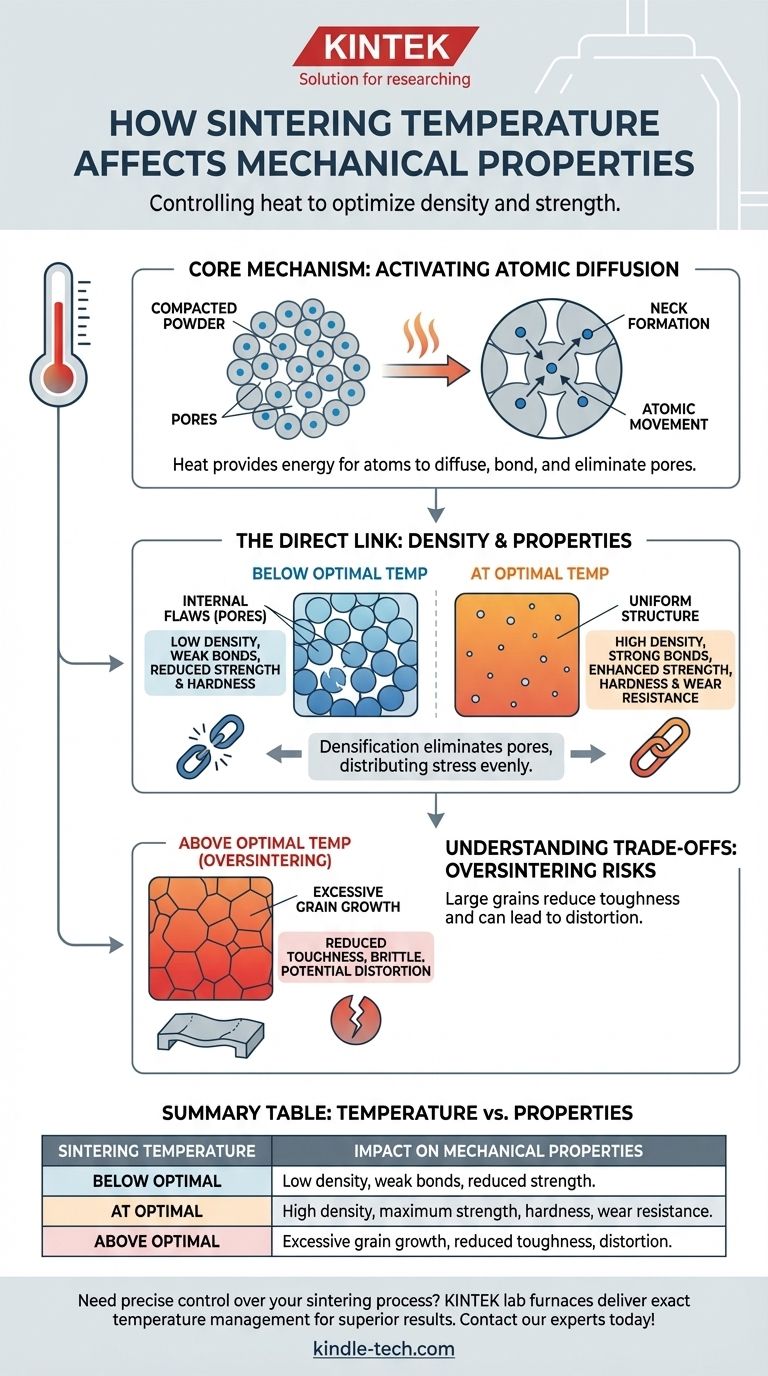

The Core Mechanism: How Temperature Drives Densification

Sintering is a thermal process for compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. Temperature is the primary variable that controls the efficiency of this transformation.

Activating Atomic Diffusion

Heat is a form of energy. Applying it to a compacted powder gives the atoms within the particles the energy they need to move, or diffuse. This atomic movement is the engine of the entire sintering process.

Neck Formation and Particle Bonding

As atoms begin to diffuse, they move across the boundaries of adjacent particles. This creates small bridges or "necks" at the points of contact. The formation of these necks is the first step in transforming a loose powder into a solid, bonded structure.

Pore Elimination and Increased Density

With sufficient temperature and time, atomic diffusion continues, moving material from the particles into the voids (pores) between them. This process systematically eliminates porosity, causing the component to shrink and become denser.

The Direct Link Between Density and Mechanical Properties

The final density of a sintered part is the most critical factor determining its performance. Higher temperatures, up to a point, directly contribute to higher density and, therefore, better mechanical properties.

Reducing Internal Flaws

Pores and voids within a material act as stress concentrators. When a load is applied, stress intensifies at the edges of these tiny holes, making them the most likely points of failure. By eliminating pores, densification creates a more uniform structure that distributes stress evenly.

Enhancing Strength, Hardness, and Wear Resistance

A denser material is inherently stronger and harder because it has more bonded mass to resist deformation and fracture. This increased hardness also improves its wear resistance, as the surface is better able to withstand abrasion and friction.

Understanding the Trade-offs: The Risk of Oversintering

Simply using the highest possible temperature is not an effective strategy. Pushing the temperature too high or holding it for too long introduces new problems that can severely compromise the material's integrity.

The Problem of Grain Growth

At excessive temperatures, the individual crystals or grains within the material can begin to merge and grow abnormally large. While this process still reduces porosity, it creates a coarse microstructure.

The Impact on Toughness

A material with excessively large grains can become brittle. This means that while it might be hard, its toughness—its ability to absorb energy and resist catastrophic failure—is significantly reduced.

The Danger of Distortion

Finally, every material has a melting point. As the sintering temperature approaches this limit, the material can begin to soften excessively, leading to slumping, distortion, or a complete loss of the component's intended shape.

Optimizing Sintering Temperature for Your Goal

The "correct" sintering temperature is not a single value but is entirely dependent on the desired outcome for the final component. Your goal determines the ideal balance between density and microstructure.

- If your primary focus is maximum strength and hardness: Your goal is to achieve the highest possible density just before the onset of rapid grain growth. This requires precise temperature control.

- If your primary focus is controlled porosity (e.g., for filters): You should use a lower temperature to encourage neck formation between particles without fully eliminating the pores.

- If your primary focus is balancing performance and cost: You may choose a moderate temperature that achieves sufficient mechanical properties for the application without incurring the high energy costs of peak temperature sintering.

Ultimately, controlling sintering temperature is the art of managing atomic behavior to build the ideal material structure for your specific need.

Summary Table:

| Sintering Temperature Effect | Impact on Mechanical Properties |

|---|---|

| Below Optimal | Low density, weak particle bonds, reduced strength and hardness |

| At Optimal | High density, strong bonds, maximum strength, hardness, and wear resistance |

| Above Optimal (Oversintering) | Excessive grain growth, reduced toughness, potential distortion |

Need precise control over your sintering process to achieve superior material properties? At KINTEK, we specialize in high-performance lab furnaces and consumables that deliver exact temperature management for consistent, reliable results. Whether you're developing advanced ceramics, metal alloys, or specialized composites, our equipment ensures optimal densification and mechanical performance. Contact our experts today to find the perfect sintering solution for your laboratory's needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What technical functions does a vacuum hot pressing sintering furnace provide? Optimize CoCrFeNi Alloy Coatings

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.

- What critical processing conditions are provided by a vacuum hot press sintering furnace? Achieve 98%+ Density.