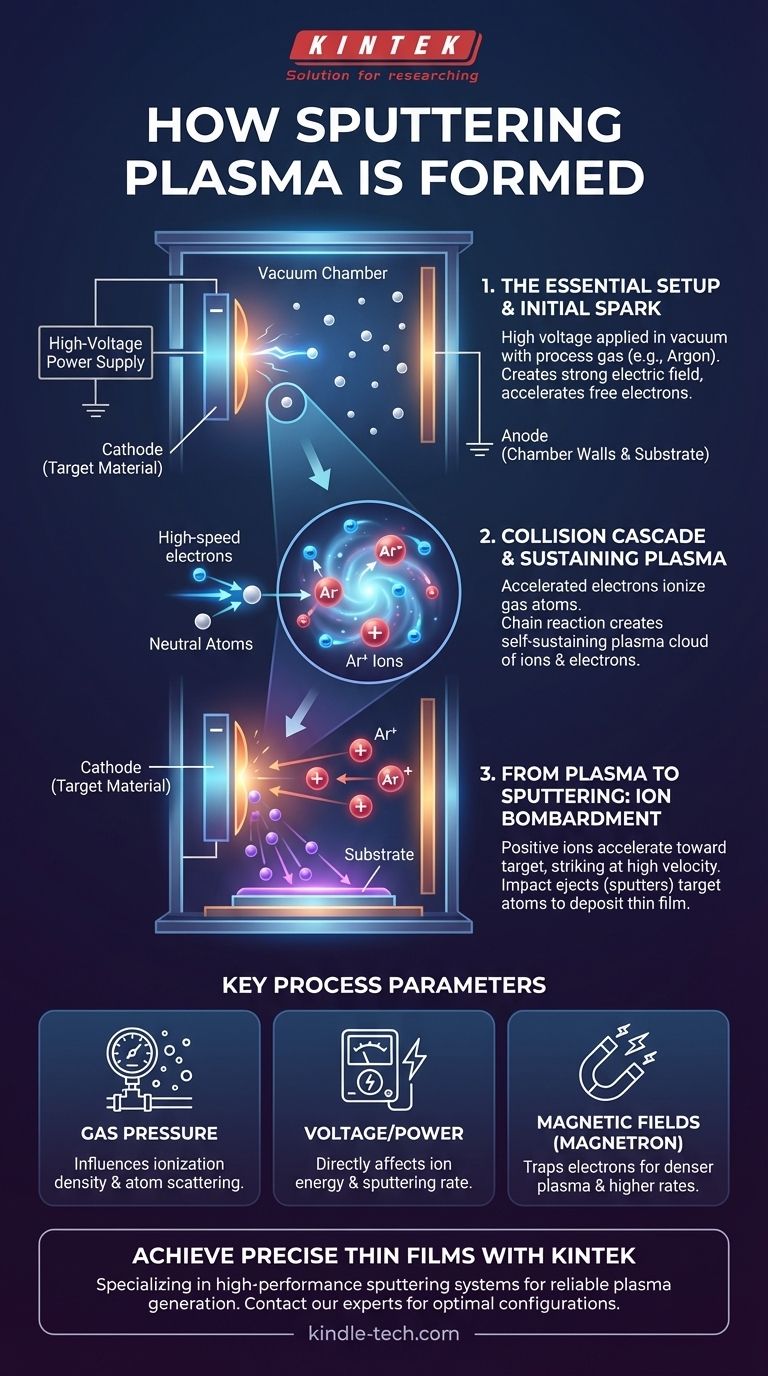

In short, plasma formation for sputtering is initiated by applying a high voltage inside a vacuum chamber filled with a process gas, typically argon. This voltage accelerates free electrons, which then collide with and ionize the gas atoms. This process creates a self-sustaining cloud of positive ions and electrons—the plasma—which provides the ions needed to bombard the target material.

The core function of the plasma is to act as a medium for generating and accelerating high-energy ions. These ions are the "projectiles" that physically knock atoms from a target material, enabling the deposition of a thin film.

The Mechanics of Plasma Generation

The Essential Setup

To create plasma, three components are required: a high-vacuum chamber, a small amount of an inert process gas (like argon), and a high-voltage power supply.

The target material is placed on a negatively charged electrode called the cathode. The chamber walls and the substrate (the material being coated) are typically connected to the electrical ground, acting as the anode.

The Initial Spark

The process begins when a high voltage is applied between the cathode and the anode. This creates a strong electric field within the chamber.

Any free electrons present in the gas are immediately and forcefully accelerated away from the negatively charged cathode.

The Collision Cascade

As these high-speed electrons travel through the chamber, they collide with neutral argon atoms.

If the collision is energetic enough, it knocks an electron loose from the argon atom. This leaves behind a positively charged argon ion (Ar+) and another free electron.

Sustaining the Plasma

This new electron is also accelerated by the electric field, leading to more collisions and creating more ions in a chain reaction.

This rapid ionization process results in a self-sustaining plasma: a glowing, energetic state of matter containing a mix of positive ions, electrons, and neutral gas atoms.

From Plasma to Sputtering

The Ion Bombardment

While the electrons are accelerated away from the target, the newly created positive argon ions are accelerated toward the negatively charged cathode where the target material is located.

These ions gain significant kinetic energy as they travel through the electric field, striking the target surface at high velocity.

Momentum Transfer and Atom Ejection

The impact of a high-energy ion triggers a series of collision cascades within the target material, similar to a break in a game of pool.

If the energy transferred to a surface atom exceeds its binding energy, that atom is physically knocked loose, or "sputtered," from the target. These ejected atoms then travel through the vacuum chamber and deposit onto the substrate, forming a thin film.

Understanding Key Process Parameters

Gas Pressure and Flow Rate

The pressure of the process gas determines the density of atoms available for ionization. Higher pressure can increase ionization efficiency but may also scatter the sputtered atoms before they reach the substrate.

Power Supply and Voltage

The applied voltage directly influences the energy of the bombarding ions. Higher voltage leads to more energetic collisions and typically increases the sputtering rate.

Magnetic Fields (Magnetron Sputtering)

In a common technique called magnetron sputtering, a magnetic field is used to trap electrons near the target surface. This greatly increases the probability of electron-atom collisions, resulting in a denser plasma at lower gas pressures and a much higher deposition rate.

Common Pitfalls to Avoid

Plasma Instability

Operating at pressures that are too low can make it difficult to sustain the plasma, leading to arcing or process failure. Conversely, excessively high pressure can reduce the mean free path, hindering the sputtering process.

Target and Substrate Damage

Excessively high ion energy can not only sputter the target but also cause damage to the substrate or implant argon ions into the growing film, affecting its properties. The process requires a precise balance of energy to be effective without being destructive.

Making the Right Choice for Your Goal

Achieving the desired film properties requires careful control over the plasma conditions.

- If your primary focus is a high deposition rate: Use a magnetron setup and increase the applied power to create a denser, more efficient plasma.

- If your primary focus is film uniformity: Optimize the gas pressure and the distance between the target and substrate to control how sputtered atoms are scattered.

- If your primary focus is delicate film chemistry: Carefully control the voltage and consider using a pulsed power supply to manage ion energy and minimize damage to the substrate.

Ultimately, mastering the sputtering process begins with a fundamental understanding of how to generate and control the plasma.

Summary Table:

| Key Parameter | Effect on Plasma & Sputtering Process |

|---|---|

| Gas Pressure | Higher pressure increases ionization but can scatter sputtered atoms. |

| Voltage/Power | Higher voltage increases ion energy and the sputtering rate. |

| Magnetic Field (Magnetron) | Traps electrons, creating denser plasma for higher deposition rates. |

Ready to achieve precise thin films with controlled sputtering plasma?

KINTEK specializes in high-performance lab equipment, including sputtering systems designed for reliable plasma generation and optimal film deposition. Our experts can help you select the right configuration—whether your goal is high deposition rates, superior film uniformity, or delicate chemistry control.

Contact our team today to discuss your specific application and how our solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing