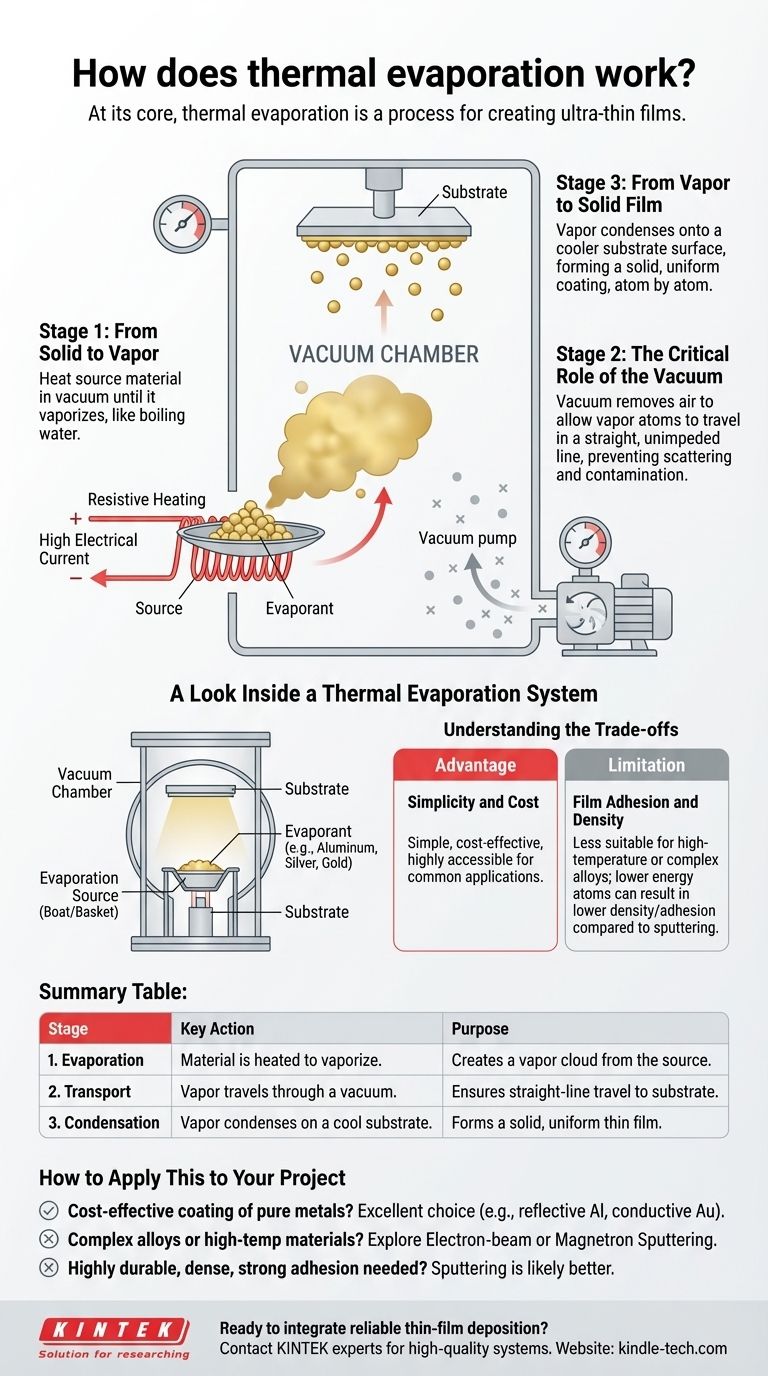

At its core, thermal evaporation is a process for creating ultra-thin films. It works by heating a source material inside a high-vacuum chamber until it vaporizes, similar to boiling water. This vapor then travels through the vacuum and condenses onto a cooler surface, known as a substrate, forming a solid, uniform coating.

The central principle of thermal evaporation is a controlled phase change. You use resistive heat to turn a solid material into a gas in a vacuum, which then allows the gas to travel unimpeded and condense back into a solid film on a target surface.

The Fundamental Principle: A Journey from Solid to Film

To truly understand thermal evaporation, it's best to think of it as a three-stage journey for the coating material. Each stage is simple, but all are critical for the process to succeed.

Stage 1: From Solid to Vapor

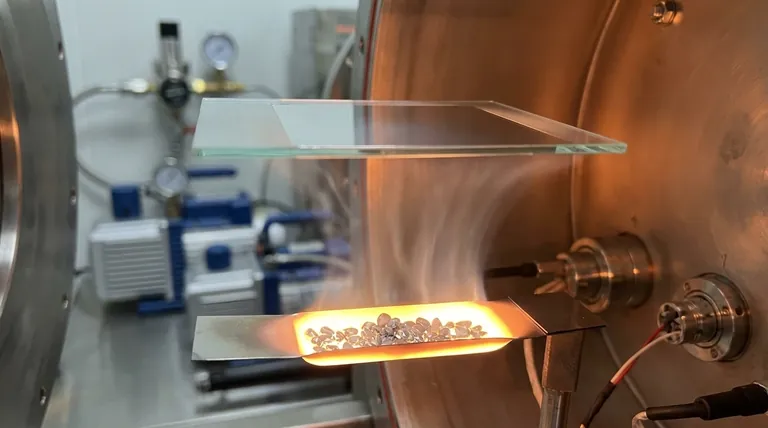

The process begins by placing the material to be deposited, called the evaporant, into a holder known as a source. This source, often a small boat or coil made of a heat-resistant metal like tungsten, acts like the heating element on a stove.

A high electrical current is passed through the source. Due to its electrical resistance, the source heats up dramatically, a process called resistive heating. This intense heat is transferred to the evaporant, causing it to melt and then evaporate (or sublime directly from solid to gas).

Stage 2: The Critical Role of the Vacuum

This all happens inside a vacuum chamber. The vacuum is not just a container; it is essential for the process. By removing almost all air molecules, the chamber ensures the vaporized atoms can travel in a straight, unimpeded line from the source to the substrate.

Without a vacuum, the vaporized atoms would collide with air, scattering randomly and reacting with gases like oxygen, preventing a clean, pure film from ever forming.

Stage 3: From Vapor to Solid Film

Positioned above the source is the substrate—the object to be coated. As the cloud of vaporized atoms travels through the vacuum, it reaches the relatively cool surface of the substrate.

Upon contact, the atoms lose their energy and condense back into a solid state, sticking to the surface. This process builds up atom by atom, creating an exceptionally thin and uniform film.

A Look Inside a Thermal Evaporation System

Every thermal evaporation system relies on a few key components working in concert to achieve this controlled deposition.

The Vacuum Chamber

This is the sealed environment, typically made of stainless steel, where the entire process takes place. It's connected to powerful pumps that remove the air to create the necessary high-vacuum conditions.

The Evaporation Source

This is the heart of the system. It's a component, often called a boat or basket, that both holds the evaporant material and generates the heat. It is designed to withstand extreme temperatures without melting or reacting with the material it holds.

The Evaporant

This is the raw coating material itself. It is often in the form of small pellets, wire, or powder. Common evaporants include pure metals like aluminum, silver, and gold, which are used in electronics and optics.

The Substrate

This is simply the item you wish to coat. It can be anything from a silicon wafer for a microchip, a piece of glass for a mirror, or a flexible polymer for an OLED display.

Understanding the Trade-offs

While effective, thermal evaporation is not the solution for every application. Its primary strength lies in its simplicity, which also informs its limitations.

Advantage: Simplicity and Cost

Thermal evaporation is one of the oldest, simplest, and most cost-effective methods of Physical Vapor Deposition (PVD). The equipment is relatively straightforward, making it highly accessible for many common applications.

Limitation: Material Compatibility

The process works best for materials with relatively low evaporation points, like pure metals. It is less suitable for materials that require extremely high temperatures (refractory metals) or for complex alloys where different components may evaporate at different rates, changing the film's composition.

Limitation: Film Adhesion and Density

The atoms in thermal evaporation arrive at the substrate with only thermal energy, which is relatively low. Compared to more energetic processes like sputtering, this can sometimes result in films with lower density and weaker adhesion to the substrate.

How to Apply This to Your Project

Choosing a deposition method depends entirely on the requirements of your final film.

- If your primary focus is cost-effective coating of pure metals: Thermal evaporation is an excellent and straightforward choice, ideal for applications like creating reflective aluminum layers or conductive gold contacts.

- If your primary focus is depositing complex alloys or high-temperature materials: You should explore alternative methods like electron-beam evaporation or magnetron sputtering, which offer more precise control and higher energy.

- If your primary focus is creating a highly durable, dense, and strongly adhered film: A more energetic process like sputtering is likely a better fit, as it bombards the substrate with high-energy ions to create a more robust film.

Ultimately, thermal evaporation remains a foundational technology for thin-film deposition due to its simplicity and effectiveness for a wide range of critical applications.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Evaporation | Material is heated to vaporize. | Creates a vapor cloud from the source. |

| 2. Transport | Vapor travels through a vacuum. | Ensures straight-line travel to substrate. |

| 3. Condensation | Vapor condenses on a cool substrate. | Forms a solid, uniform thin film. |

Ready to integrate reliable thin-film deposition into your workflow?

At KINTEK, we specialize in providing high-quality lab equipment, including thermal evaporation systems, to meet your specific research and production needs. Whether you are developing microchips, optical coatings, or advanced materials, our expertise ensures you get the right solution for depositing pure metals like aluminum, gold, and silver efficiently and cost-effectively.

Contact our experts today to discuss how a KINTEK thermal evaporation system can enhance your lab's capabilities and accelerate your project success.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition