From a physics standpoint, electric heating elements are nearly 100% efficient. This is because their sole purpose is to convert electrical energy into thermal energy. Due to the principle of resistive heating, virtually every watt of electricity that flows through the element is dissipated directly as heat, with negligible losses to other forms like light or sound.

While electric resistance heaters are almost perfectly efficient at converting electricity into heat, this is not the same as being cost-effective. The true measure of a heating system is its ability to deliver useful heat reliably, for the lowest operational cost and for the longest possible lifespan.

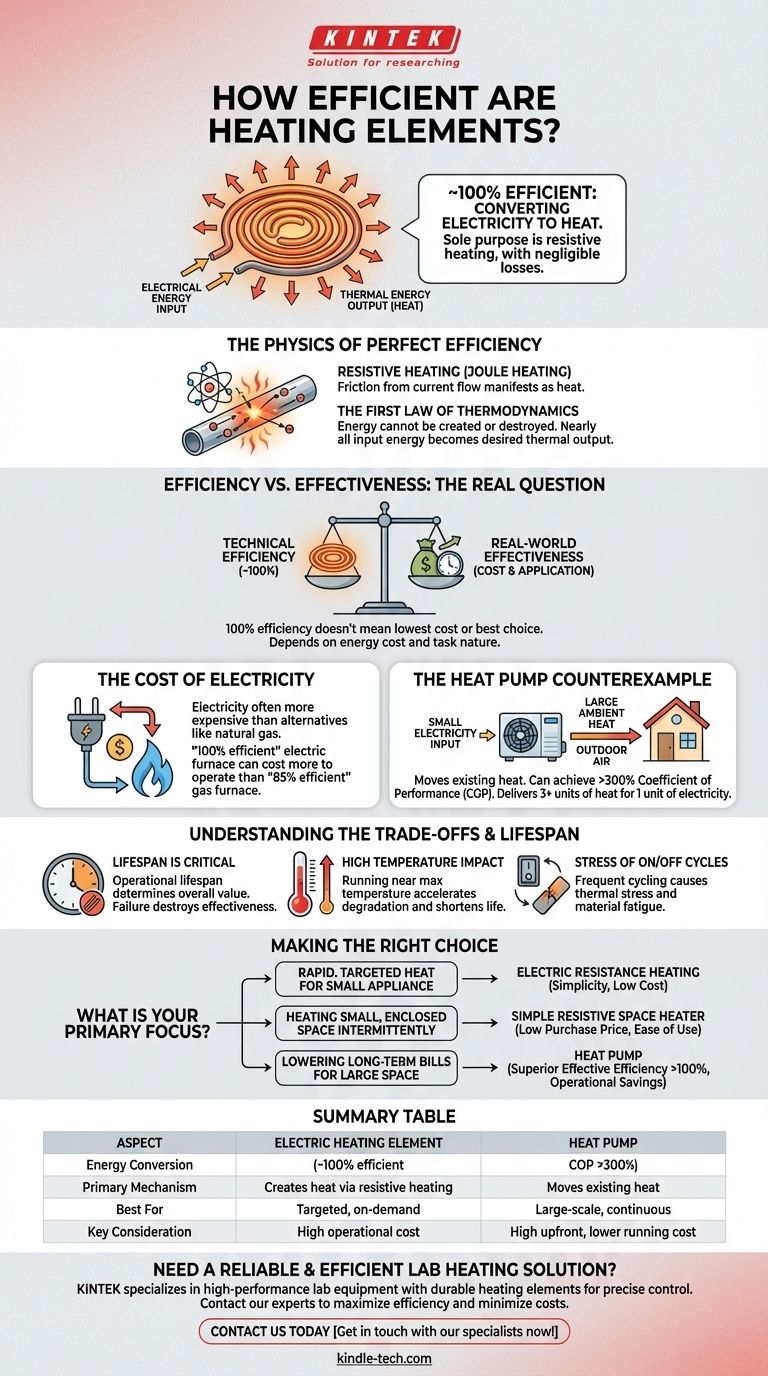

The Physics of Perfect Efficiency

To understand why a simple heating element is so efficient, we need to look at the fundamental process at work. It operates on a principle that leaves little room for energy to be wasted.

What is Resistive Heating?

Resistive heating, also known as Joule heating, occurs when an electric current passes through a conductor. The conductor's resistance to the flow of electricity causes friction on an atomic scale, which manifests as heat.

Where Does the Energy Go?

Unlike an electric motor, which aims to produce motion and loses energy to heat and sound, a heating element's only intended output is heat.

The First Law of Thermodynamics dictates that energy cannot be created or destroyed. In this case, electrical energy is converted directly into thermal energy. Because the system is so simple, nearly all the input energy becomes the desired output.

Efficiency vs. Effectiveness: The Real Question

The 100% efficiency figure is technically correct but can be misleading. It doesn't mean resistive heating is the best or most economical choice for every application. The real-world effectiveness of a heating system depends on the cost of the input energy and the nature of the task.

The Cost of Electricity

While the conversion of electricity to heat is efficient, electricity itself is often a more expensive form of energy than alternatives like natural gas. A "100% efficient" electric furnace can easily be more expensive to operate than an "85% efficient" gas furnace.

The Heat Pump Counterexample

A heat pump does not create heat; it moves existing heat from one place to another. By using a small amount of electricity to transfer a large amount of ambient heat, it can achieve a "coefficient of performance" of 300% or more.

For every one unit of electricity it consumes, it can deliver three or more units of heat into a space. This makes it far more effective for applications like whole-home heating.

Application is Everything

Resistive heating excels where its simplicity and low initial cost are paramount. It is the ideal choice for targeted, on-demand applications like toasters, clothes irons, and portable space heaters. For larger, continuous heating tasks, its high operational cost becomes a significant disadvantage.

Understanding the Trade-offs and Lifespan

An element's efficiency is irrelevant if it fails prematurely. The operational lifespan is a critical factor in its overall value and effectiveness, and it is directly influenced by how the element is used.

Lifespan is a Critical Factor

A heating element's useful life is determined by factors that cause its material to degrade over time. An element that is 100% efficient at converting electricity to heat but fails after only a few hours of use is not an effective solution.

The Impact of High Temperatures

The single most critical factor affecting an element's life is its operating temperature. Running an element near its maximum temperature limit dramatically accelerates oxidation and material degradation, leading to a much shorter lifespan.

The Stress of On/Off Cycles

Frequent cycling between hot and cold creates significant thermal stress. The constant expansion and contraction of the element's material can lead to cracks and mechanical failure over time. Continuous operation at a moderate temperature is often less damaging than frequent, high-temperature bursts.

Making the Right Choice for Your Goal

Choosing the right heating technology requires looking beyond simple efficiency numbers and focusing on your specific application and priorities.

- If your primary focus is rapid, targeted heat for a small appliance: Electric resistance heating is unparalleled in its simplicity, low cost, and direct effectiveness.

- If your primary focus is heating a small, enclosed space intermittently: A simple resistive space heater is often the most sensible choice due to its low purchase price and ease of use.

- If your primary focus is lowering long-term energy bills for a large space: A heat pump is vastly superior, moving heat with an effective efficiency far exceeding 100% and offering significant operational savings.

Understanding the difference between an element's technical efficiency and a system's overall effectiveness is the key to making an informed decision.

Summary Table:

| Aspect | Electric Heating Element | Heat Pump |

|---|---|---|

| Energy Conversion | ~100% efficient | Coefficient of Performance (COP) > 300% |

| Primary Mechanism | Creates heat via resistive heating | Moves existing heat |

| Best For | Targeted, on-demand applications (e.g., lab furnaces) | Large-scale, continuous space heating |

| Key Consideration | High operational cost of electricity | High upfront cost, lower running cost |

Need a reliable and efficient heating solution for your laboratory?

At KINTEK, we specialize in high-performance lab equipment, including furnaces with durable heating elements designed for precise temperature control and long-term reliability. Our experts can help you select the right system to maximize efficiency and minimize operational costs for your specific application.

Contact us today to discuss your laboratory heating needs and discover how our solutions can enhance your research and processes.

Get in touch with our specialists now!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

People Also Ask

- How are PTC cartridge heaters used? Self-Regulating Precision for Direct Immersion and Contact Heating

- Do heating elements use a lot of electricity? Understanding High Energy Consumption and Efficient Alternatives

- What is the purpose of multi-stage electric heating in tensile testing? Achieve Precision in Grain Boundary Analysis

- Does molybdenum conduct heat? Unlocking Its Role in High-Temperature Applications

- How does a resistive heating element work? Convert Electricity to Heat Efficiently

- What is molybdenum highest melting point? 2622°C for Extreme Heat Applications

- What is the purpose of using a Pt-Rh thermocouple in magnesium experiments? Ensure Precise Vapor Collection

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace