In short, induction heating is a highly efficient process. Its effectiveness comes from its unique ability to generate heat directly inside the workpiece itself, rather than transferring it from an external source. This direct, non-contact method results in rapid heating, precise control, and significantly less wasted energy compared to traditional flame or furnace techniques.

The core reason for induction heating's high efficiency is simple: it bypasses the slow and wasteful process of external heat transfer. By using a magnetic field to create heat internally, energy is delivered precisely where it's needed, minimizing loss to the surrounding environment.

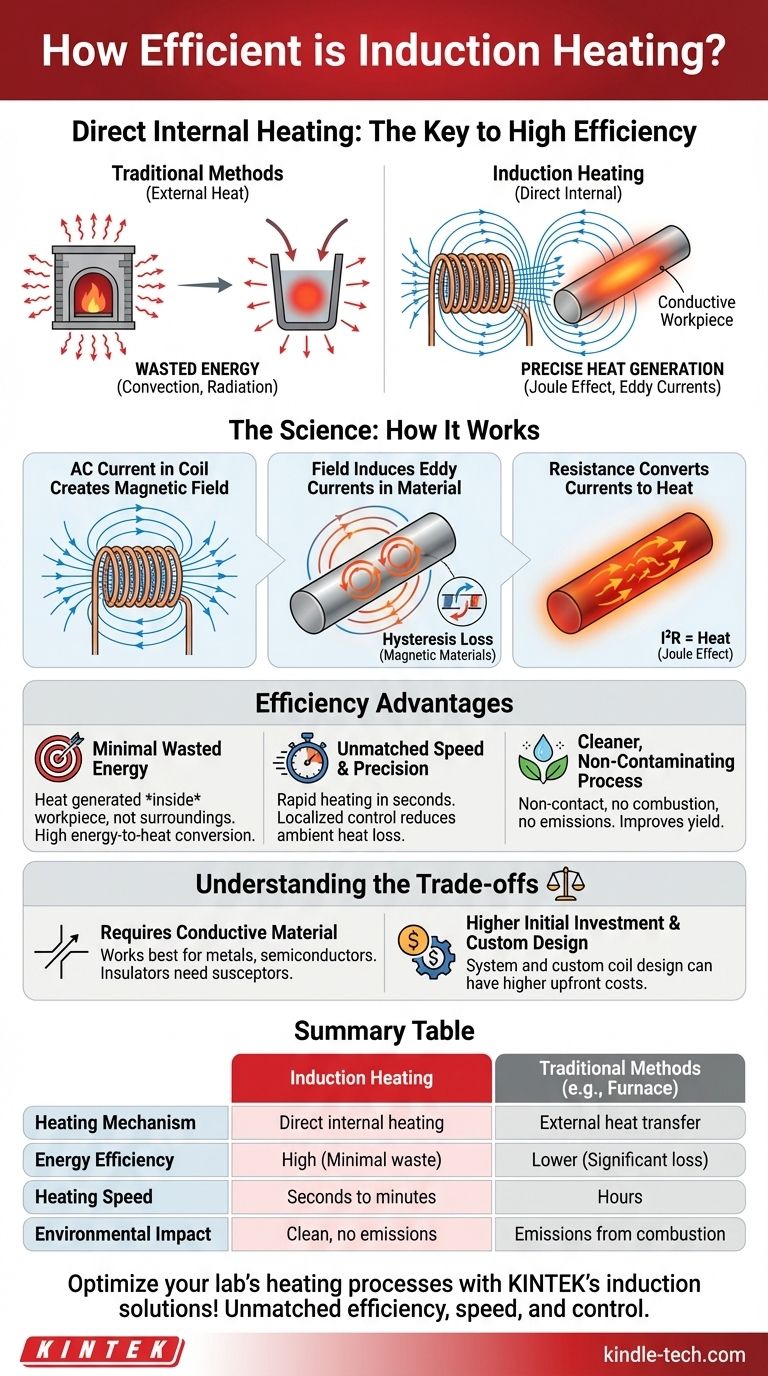

The Science of Direct, Internal Heating

To understand the efficiency of induction, you must first understand its mechanism. Unlike a conventional oven that heats the air to heat an object, induction heating makes the object its own heat source.

The Role of the Magnetic Field

The process begins with a high-frequency alternating current (AC) passing through an induction coil, typically made of copper. This creates a powerful and rapidly changing magnetic field in the space within and around the coil.

Generating Eddy Currents

When an electrically conductive material, like metal or a graphite crucible, is placed into this magnetic field, the field induces circular electric currents within the material. These are known as eddy currents.

The Joule Heating Effect

As these eddy currents flow through the material, they encounter electrical resistance. This resistance converts the electrical energy of the currents directly into heat. This phenomenon is known as the Joule heating effect, and it is the primary source of heat in the induction process.

Hysteresis Losses in Magnetic Materials

For magnetic materials like iron, there is a secondary heating effect. The rapidly alternating magnetic field causes the magnetic domains within the material to flip back and forth, creating internal friction and generating additional heat. This is known as hysteresis loss.

The Efficiency Advantage Over Traditional Methods

The internal heating mechanism gives induction a fundamental advantage over methods that rely on conduction, convection, and radiation from an external source.

Minimal Wasted Energy

In a traditional furnace, a massive amount of energy is wasted heating the furnace walls, the air inside, and the surrounding atmosphere. Induction heating avoids this almost entirely. The only heat produced is within the workpiece, leading to a much higher energy-to-heat conversion efficiency.

Unmatched Speed and Precision

Because heat is generated instantly and internally, workpieces can be brought to temperature in seconds or minutes, not hours. This speed further improves overall efficiency by reducing the time available for ambient heat loss. The magnetic field can also be shaped by the coil design to heat only a very specific area of a part.

A Cleaner, Non-Contaminating Process

Induction is a non-contact process. The part never touches a flame or heating element, which eliminates product contamination from combustion byproducts. This improves process yield and reduces waste, contributing to overall operational efficiency. It is also a green technology, as it produces no harmful emissions.

Understanding the Trade-offs

While highly efficient, induction heating is not a universal solution. An objective analysis requires understanding its specific requirements and limitations.

Material-Specific Application

The primary requirement for induction heating is that the target material must be electrically conductive. It works exceptionally well for metals and semiconductors but cannot directly heat insulators like plastics, glass, or ceramics unless a conductive susceptor (like a graphite crucible) is used to hold them.

Initial Investment and Coil Design

Induction heating systems, which include a power supply and a custom coil, often have a higher initial capital cost than simple flame or resistance heaters. Furthermore, the induction coil must be designed and tuned for the specific size and shape of the part being heated to ensure maximum efficiency.

System vs. Process Efficiency

While the energy transfer from the coil to the part is extremely efficient, the overall system efficiency also depends on the power supply's ability to convert mains electricity into high-frequency AC. Modern solid-state power supplies are very effective, but this conversion is not 100% lossless. Even so, the total system efficiency of induction regularly surpasses traditional methods.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on your project's priorities.

- If your primary focus is speed, precision, and repeatability: Induction heating is the superior choice for high-volume manufacturing where consistent quality is critical.

- If your primary focus is energy efficiency and environmental impact: Induction's direct heating mechanism makes it one of the greenest and most energy-conscious technologies available.

- If your primary focus is heating diverse, non-conductive materials on a small scale: A conventional oven or furnace may offer more flexibility despite its lower energy efficiency.

Ultimately, understanding that induction heating's efficiency comes from its internal, direct-energy-transfer mechanism empowers you to select the best tool for the job.

Summary Table:

| Aspect | Induction Heating | Traditional Methods (e.g., Furnace) |

|---|---|---|

| Heating Mechanism | Direct internal heating via eddy currents | External heat transfer (conduction/convection) |

| Energy Efficiency | High (minimal wasted energy) | Lower (energy lost to surroundings) |

| Heating Speed | Seconds to minutes | Hours |

| Precision & Control | Excellent (localized heating) | Limited |

| Environmental Impact | Clean, no emissions | Emissions from combustion |

Optimize your lab’s heating processes with KINTEK’s induction solutions!

Whether you’re melting metals, sintering materials, or conducting precise thermal experiments, our induction heating systems deliver unmatched efficiency, speed, and control. Reduce energy waste and improve reproducibility in your laboratory workflows.

Contact our experts today to explore how KINTEK’s lab equipment can elevate your research and production efficiency.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Lab-Scale Vacuum Induction Melting Furnace

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why is heating rate control essential for LOCA simulation tests? Ensure Precision in Nuclear Safety Research

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What technical advantages does a vacuum hot press furnace offer? Achieve Superior Densification in Al-Si Composites

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?