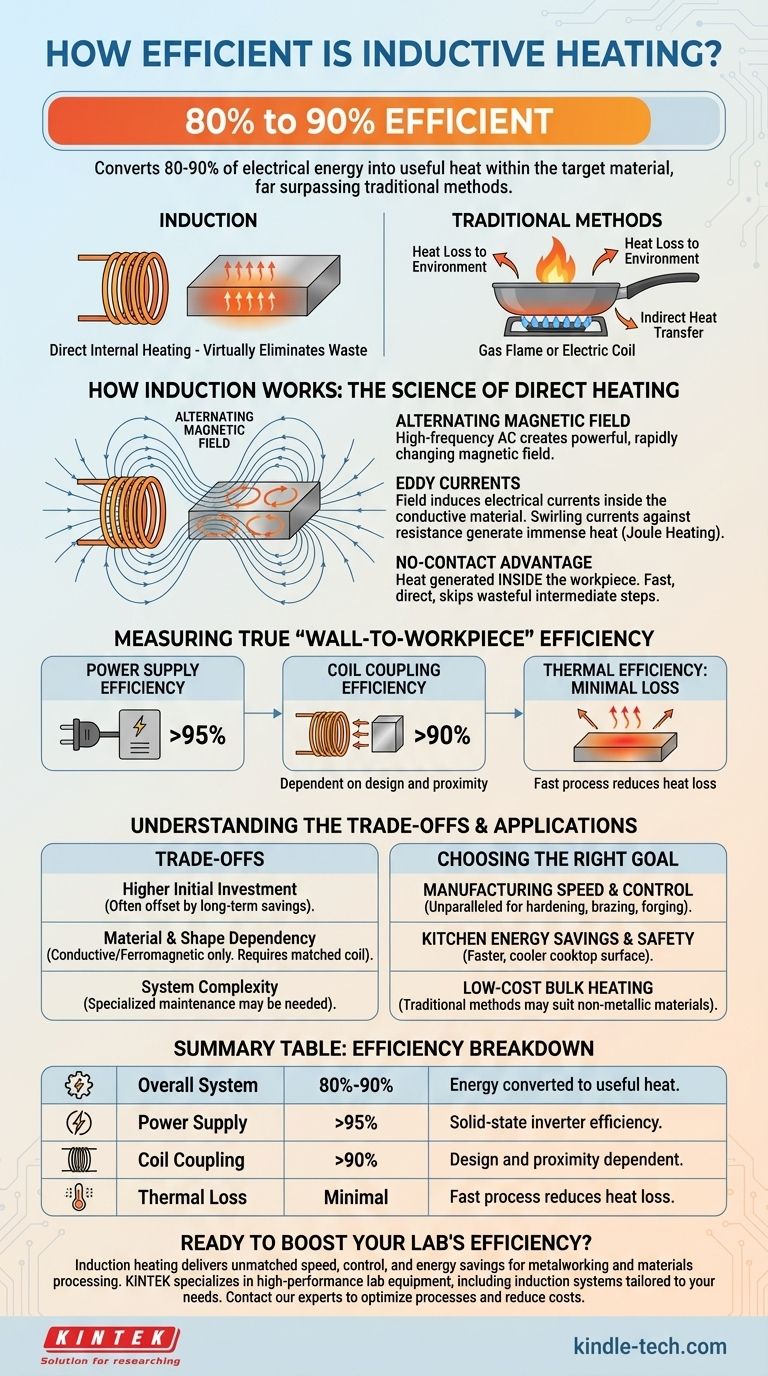

In short, inductive heating is exceptionally efficient. It typically converts 80% to 90% of its electrical energy into useful heat within the target material. This level of efficiency far surpasses traditional methods like gas furnaces or electric resistance heaters, where a significant amount of energy is lost to the surrounding environment.

The core principle behind induction's high efficiency is its method of heat generation. Instead of creating heat externally and transferring it to an object, induction generates heat directly inside the object itself, virtually eliminating the primary sources of energy waste.

How Induction Works: The Science of Direct Heating

Understanding why induction is so efficient requires a look at how it fundamentally differs from other heating methods. It isn't about convection or conduction from an external source; it's about internal energy conversion.

The Alternating Magnetic Field

An induction heating system uses a coil of wire through which a high-frequency alternating current (AC) is passed. This current creates a powerful and rapidly changing magnetic field around the coil.

Eddy Currents: The Main Source of Heat

When an electrically conductive material, like a steel pan or an industrial component, is placed within this magnetic field, the field induces electrical currents within the metal. These are known as eddy currents.

These currents swirl inside the material against its natural electrical resistance, generating immense heat through a process called Joule heating. Think of it as controlled, high-intensity electrical friction.

The Advantage of "No-Contact" Heating

Because the heat is generated inside the workpiece, the process is incredibly fast and direct. A gas flame heats the air and the exterior of a pot before the pot can heat its contents. An electric coil must heat itself before it can heat a pan. Induction skips these wasteful intermediate steps entirely.

Measuring True "Wall-to-Workpiece" Efficiency

The 80-90% figure refers to the total system efficiency, from the electrical outlet to the final heated part. This can be broken down into a few key stages where minor losses occur.

Power Supply Efficiency

The first component is the power supply, which converts standard AC power into the high-frequency AC needed for the induction coil. Modern solid-state power supplies are extremely efficient, often operating at over 95% efficiency.

Coil Coupling Efficiency

This is the most significant variable. It measures how effectively the magnetic field generated by the coil "couples" with the workpiece to induce current. A well-designed system with a coil close to the workpiece can achieve coupling efficiencies well over 90%. A poorly matched coil or a large air gap will reduce this number.

Thermal Efficiency

This refers to how much of the heat generated within the part actually contributes to the desired outcome (e.g., melting metal) versus how much is lost to the surrounding air via radiation. Because induction is so fast, there is simply less time for the part to lose heat, making its thermal efficiency superior to slow, prolonged heating processes.

Understanding the Trade-offs

Despite its high efficiency, induction heating is not a universal solution. Its targeted nature brings specific limitations that are critical to understand.

Higher Initial Investment

Induction heating systems, whether for industrial use or a home cooktop, generally have a higher upfront cost compared to their gas or resistance-based counterparts. However, this is often offset by lower long-term energy costs and increased productivity.

Material and Shape Dependency

The most significant limitation is that induction only works directly on materials that are electrically conductive and, ideally, ferromagnetic (like iron and many steels). You cannot use it to directly heat glass, most ceramics, or plastics.

Furthermore, the shape and size of the induction coil must be carefully matched to the part being heated to ensure efficient energy transfer.

System Complexity

The underlying technology, involving high-frequency electronics and precisely engineered coils, is more complex than a simple gas burner or resistance coil. This can mean more specialized maintenance and repair.

Making the Right Choice for Your Goal

Selecting a heating technology depends entirely on balancing efficiency with the requirements of your specific application.

- If your primary focus is process control and speed in manufacturing: Induction is unparalleled, offering rapid, repeatable, and precisely controlled heating for tasks like hardening, brazing, or forging.

- If your primary focus is energy savings and safety in a kitchen: An induction cooktop is the most efficient choice, delivering faster heating than gas or electric while keeping the cooktop surface itself cool.

- If your primary focus is low-cost, bulk heating of diverse materials: A traditional convection oven or gas furnace may be a more practical choice, especially if the materials are non-metallic.

Ultimately, induction's high efficiency is a direct result of its precise and targeted method of energy transfer.

Summary Table:

| Aspect | Efficiency | Key Detail |

|---|---|---|

| Overall System | 80% - 90% | Energy converted to useful heat in the workpiece. |

| Power Supply | > 95% | Modern solid-state inverter efficiency. |

| Coil Coupling | > 90% | Depends on coil design and proximity to the part. |

| Thermal Loss | Minimal | Fast process reduces heat loss to surroundings. |

Ready to Boost Your Lab's Efficiency with Precision Heating?

Induction heating delivers unmatched speed, control, and energy savings for your metalworking and materials processing applications. KINTEK specializes in high-performance lab equipment, including induction heating systems tailored to your specific needs.

Contact our experts today to discuss how an induction heating solution can optimize your processes, reduce energy costs, and improve your results.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- Why is maintaining a high-vacuum environment necessary when using a vacuum hot pressing furnace? Expert Insights

- What are the primary functions of a vacuum hot press furnace? Optimize WC/Cu-Zr-Ti Composite Consolidation

- Why is a vacuum environment necessary for sintering ZrB2-SiC composites? Master High-Performance Ceramic Fabrication