In short, tyre pyrolysis oil is manufactured by heating shredded tires to high temperatures (typically 400-600°C) inside a sealed, oxygen-free reactor. This process, known as pyrolysis, breaks down the complex rubber polymers into three primary products: a liquid crude oil (TPO), a solid carbon char, and a synthetic gas. The lack of oxygen is critical, as it ensures the material decomposes thermally rather than burning.

The core of tyre pyrolysis is not merely heating, but a controlled thermal decomposition. It transforms a problematic waste stream into valuable commodities, but the quality of these outputs—and the process's overall viability—depends entirely on meticulous preparation, precise temperature control, and effective management of all byproducts.

The Core Principle: Decomposition Without Combustion

What is Pyrolysis?

Pyrolysis is a chemical process that breaks down complex organic materials using heat in the absence of oxygen. Preventing oxygen from entering the system is the key that differentiates it from incineration or burning.

Instead of combusting and releasing energy as fire, the long-chain molecules that make up the tire's rubber and synthetic components vibrate and break apart into smaller, simpler molecules.

From Solid Polymer to Liquid, Solid, and Gas

A tire is a highly engineered product made of long, cross-linked polymer chains. Pyrolysis effectively reverses the manufacturing process, breaking these robust chains.

The result is a mixture of outputs: shorter liquid hydrocarbon chains (the pyrolysis oil), a stable solid carbon residue (the char or recovered carbon black), and light, non-condensable hydrocarbon gases (syngas).

The Step-by-Step Manufacturing Process

A commercial tyre pyrolysis plant operates through a series of well-defined stages, each critical to the efficiency and quality of the final products.

Step 1: Feedstock Preparation

Raw, end-of-life tires are not suitable for direct processing. They must first be prepared, a step that is crucial for a smooth and efficient operation.

This involves shredding the tires into small, uniform pieces (typically 1-2 inches). During this stage, the embedded steel wiring and nylon or polyester fibers are mechanically separated and removed. Clean, consistently sized feedstock ensures even heating and prevents reactor blockages.

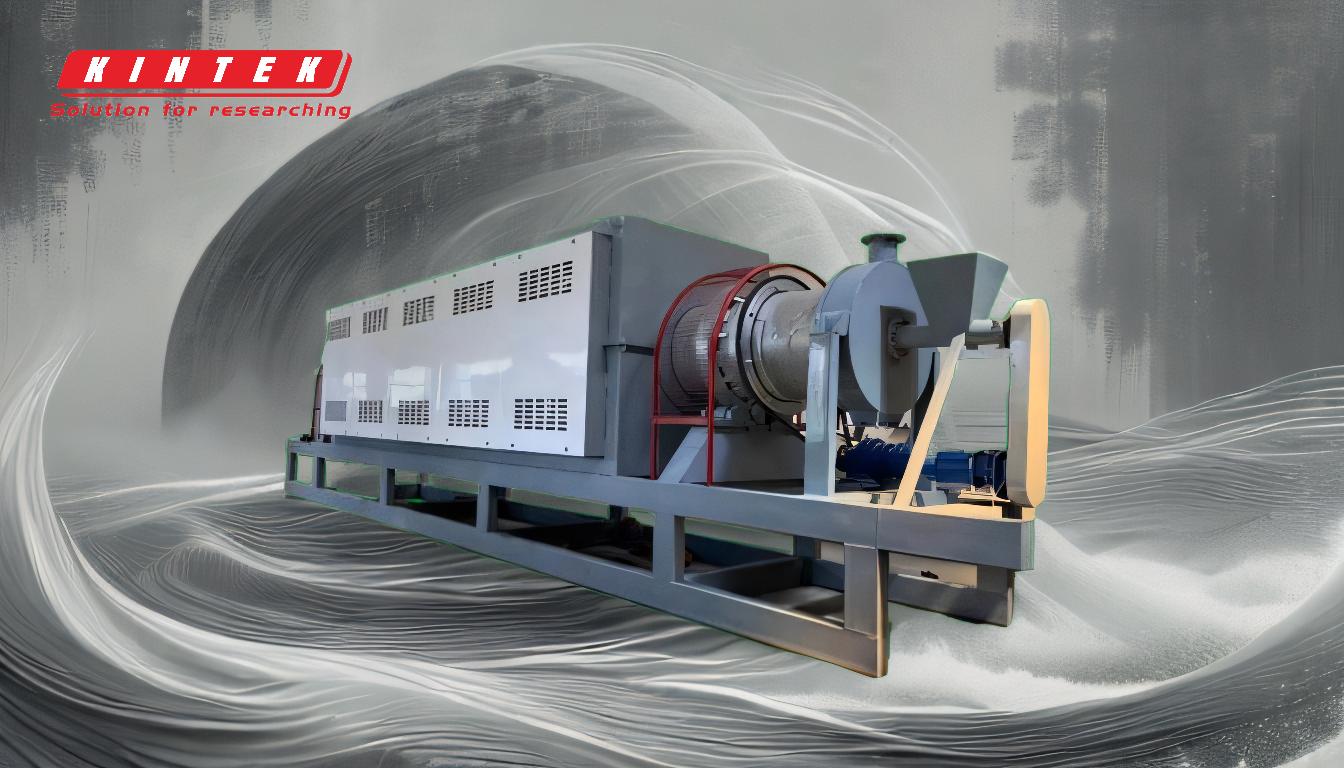

Step 2: The Pyrolysis Reactor

The shredded tire material is fed into the pyrolysis reactor, which is the heart of the system. The reactor is an airtight vessel designed to withstand high temperatures and pressures.

The material is then heated indirectly. A popular method involves rotating the reactor (like a kiln) to tumble the material, ensuring all of it reaches the target temperature of 400°C to 600°C. The process can be run in batches or continuously, depending on the scale of the operation.

Step 3: Vapourisation and Condensation

As the temperature inside the reactor rises, the rubber decomposes and vaporizes into a hot gas. This gas, a mix of hydrocarbon vapors, is piped out of the reactor.

It is then directed into a series of condensers. These units use a cooling medium (like water) to rapidly lower the temperature of the gas, causing the heavier hydrocarbon chains to condense back into a liquid—this liquid is the tyre pyrolysis oil (TPO).

Step 4: Product Separation and Collection

The process yields three distinct output streams that are collected separately.

- The Liquid: The condensed TPO is collected in storage tanks.

- The Solid: The solid residue, known as carbon char or recovered Carbon Black (rCB), remains in the reactor and is removed after the cycle is complete.

- The Gas: Any vapors that do not condense into liquid are collected as non-condensable gas, or "syngas." This gas is rich in energy and is almost always recycled to power the burners that heat the reactor, making the plant more energy self-sufficient.

Understanding the Trade-offs and Challenges

While pyrolysis is a powerful recycling technology, it comes with significant operational challenges that must be managed to ensure both environmental safety and economic viability.

Oil Quality and Post-Processing

Tyre pyrolysis oil is a crude, unrefined product. It is often thick, dark, and has a high sulfur content inherited from the vulcanization process used to make tires.

It cannot be used as a direct substitute for diesel or gasoline in engines without significant refining, such as distillation and hydrodesulfurization. Its most common application is as a heavy fuel oil for industrial furnaces, boilers, and power plants.

Byproduct Value and Consistency

The economic success of a pyrolysis plant often hinges on the value of its byproducts. The recovered steel has a straightforward market value as scrap metal.

However, the carbon char is of lower quality than virgin carbon black. Its properties can be inconsistent, limiting its use to lower-value applications like solid fuel, pigments in construction materials, or as a filler in low-grade rubber products.

Environmental and Safety Controls

Operating a pyrolysis plant demands stringent safety and environmental protocols. Handling hot, flammable gases and liquids requires robust engineering controls to prevent leaks and accidents.

Furthermore, incomplete combustion or leaks can release harmful pollutants. A professional operation must include advanced scrubbing and filtration systems to manage emissions and ensure compliance with environmental regulations.

Making the Right Choice for Your Goal

Understanding the fundamentals of the pyrolysis process allows you to evaluate its suitability for your specific objective.

- If your primary focus is waste management: Pyrolysis is an excellent method for diverting a significant waste stream from landfills and recovering its inherent material and energy value.

- If your primary focus is energy production: TPO is a proven industrial fuel source, but you must account for its crude nature and the infrastructure needed to handle and burn it cleanly.

- If your primary focus is circular economics: The viability of your project will depend on securing markets for all three outputs—oil, carbon char, and steel—not just the oil alone.

Tyre pyrolysis is a technically demanding but promising solution to the global challenge of end-of-life tire waste.

Summary Table:

| Step | Process | Key Details |

|---|---|---|

| 1 | Feedstock Preparation | Shredding tires (1-2 inches), removing steel/fibers |

| 2 | Pyrolysis Reactor | Heating to 400-600°C in an oxygen-free, sealed vessel |

| 3 | Condensation | Cooling hydrocarbon vapors to liquid form (TPO) |

| 4 | Product Collection | Separating oil, carbon char (rCB), and syngas |

Ready to transform tire waste into valuable resources? KINTEK specializes in providing robust laboratory equipment and consumables to support your pyrolysis research and development. Whether you're optimizing your process or analyzing product quality, our solutions help you achieve precise temperature control and reliable results. Contact our experts today to discuss how we can support your laboratory's tire pyrolysis projects!

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is cold isostatic pressing used for? Achieve Uniform Density in Complex Parts

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- What are the advantages of cold isostatic pressing? Achieve Superior Density and Complex Shapes

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts