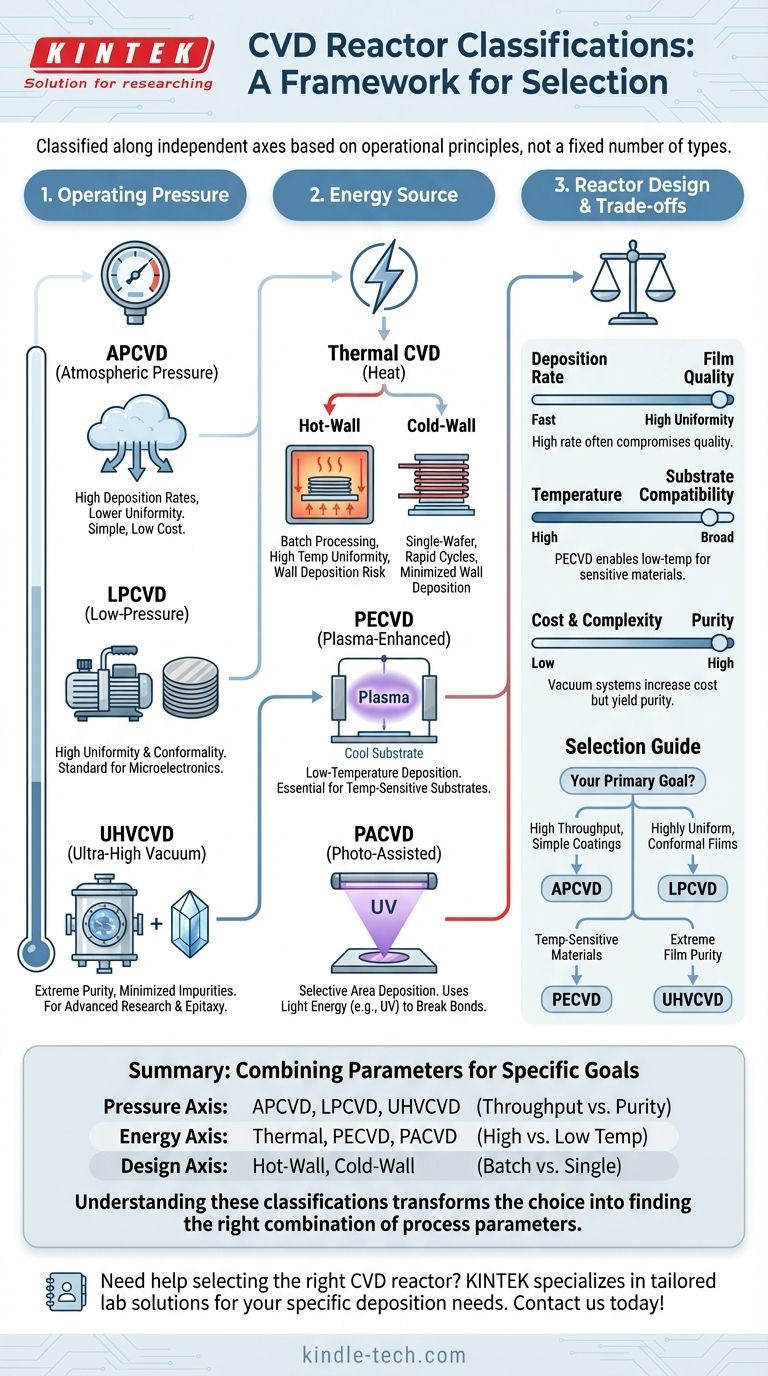

Rather than being categorized into a fixed number of types, Chemical Vapor Deposition (CVD) reactors are classified along several independent axes based on their operational principles. The most common classifications are based on operating pressure, the method used to energize the chemical reaction, and how the precursor chemicals are delivered. Understanding these parameters is key to selecting the correct process for a specific material.

The "type" of a CVD reactor is not a single label but a combination of choices—pressure, temperature, and energy source—each representing a trade-off between deposition speed, film quality, cost, and substrate compatibility.

The Primary Classification Axes

CVD is a process where a solid material—a thin film—is grown on a substrate from chemical precursors in a vapor phase. The various reactor designs exist to control this process with precision, and they are best understood by how they manage three key variables: pressure, energy, and precursor delivery.

Classification by Operating Pressure

The pressure inside the reactor chamber fundamentally changes how gas molecules behave, directly impacting the quality and uniformity of the resulting film.

Atmospheric Pressure CVD (APCVD) This method operates at standard atmospheric pressure. It is relatively simple and inexpensive, allowing for high deposition rates. However, the high pressure leads to gas-phase reactions and lower film uniformity.

Low-Pressure CVD (LPCVD) Operating at reduced pressure (typically 0.1-100 Pa) significantly increases the mean free path of gas molecules. This allows them to travel further before colliding, resulting in highly uniform and conformal films, which is critical for microelectronics. Deposition rates are lower than in APCVD.

Ultra-High Vacuum CVD (UHVCVD) This is a specialized form of LPCVD operating under extremely low pressures. The primary benefit is minimizing the incorporation of impurities into the film, leading to exceptional purity. It is primarily used for advanced research and growing high-quality epitaxial layers, like silicon-germanium.

Classification by Energy Source

A chemical reaction requires energy. How this energy is supplied to the precursor gases is another major differentiator between CVD systems.

Thermal CVD (Hot-Wall and Cold-Wall)

This is the most fundamental method, using heat to initiate the reaction.

A hot-wall reactor heats the entire chamber, including the chamber walls and the substrates. This approach is excellent for batch processing many wafers at once with high temperature uniformity, but it can lead to film deposition on the chamber walls, which consumes precursors and can become a source of particle contamination.

A cold-wall reactor selectively heats only the substrate, leaving the chamber walls cool. This minimizes unwanted deposition on the walls and is common for single-wafer processing, allowing for rapid heating and cooling cycles.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas). This highly energetic plasma can break down precursor gas molecules at much lower temperatures than thermal CVD requires. This is the defining advantage of PECVD, making it essential for depositing films on substrates that cannot withstand high heat, such as plastics or fully processed silicon wafers.

Photo-Assisted CVD (PACVD)

In this specialized technique, light—typically ultraviolet (UV)—is used to supply the energy needed to break precursor chemical bonds. Because the light can be focused, it allows for selective area deposition without the need for masks.

Understanding the Trade-offs

Choosing a CVD method involves balancing competing priorities. There is no single "best" reactor; there is only the best tool for a specific application.

Deposition Rate vs. Film Quality

Generally, conditions that favor high deposition rates, like atmospheric pressure, can compromise film quality, leading to poor uniformity and structure. Slower, more controlled processes like LPCVD produce superior films.

Temperature vs. Substrate Compatibility

High temperatures often produce crystalline films with excellent properties. However, these temperatures will damage or destroy many substrates. This is the critical trade-off that PECVD was designed to solve, enabling quality film deposition at low temperatures.

Cost & Complexity vs. Purity

APCVD systems are the simplest and cheapest to build and operate. As you move toward LPCVD and especially UHVCVD, the need for sophisticated vacuum pumps, seals, and control systems dramatically increases the cost and complexity in exchange for superior uniformity and purity.

Selecting the Right CVD Approach for Your Goal

Your choice of CVD technology should be driven entirely by the requirements of your final product.

- If your primary focus is high throughput and low cost for simple coatings: APCVD is often the most practical starting point.

- If your primary focus is highly uniform, conformal films for microelectronics: LPCVD is the established industry standard.

- If your primary focus is depositing films on temperature-sensitive materials: PECVD is the essential and often only choice.

- If your primary focus is fundamental research requiring extreme film purity: UHVCVD provides the necessary controlled environment.

Ultimately, understanding these classifications transforms the question from "how many types are there?" to "which combination of process parameters will achieve my material goals?"

Summary Table:

| Classification Axis | Key Types | Primary Use Case |

|---|---|---|

| Operating Pressure | APCVD, LPCVD, UHVCVD | High throughput, uniformity, or extreme purity |

| Energy Source | Thermal CVD, PECVD, PACVD | High-temperature or low-temperature deposition |

| Reactor Design | Hot-Wall, Cold-Wall | Batch processing vs. single-wafer processing |

Need help selecting the right CVD reactor for your lab? KINTEK specializes in lab equipment and consumables, offering tailored solutions for your specific deposition needs—whether you require high uniformity, low-temperature processing, or high-purity films. Contact us today to discuss how our expertise can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the problems with CVD? Key Challenges in High-Temperature Coating

- What are the techniques for thin film deposition? Choose the Right Method for Your Application

- What is the process of silicon deposition? A Step-by-Step Guide to Thin-Film Fabrication

- What is the step of CVD process? Master the Key Stages for Superior Thin Films

- What are the primary manufacturing technologies for synthetic diamonds? Compare HPHT, CVD, and Niche Methods

- What are the advantages of ALD over CVD? Achieve Atomic-Level Precision for Your Thin Films

- What is the synthesis process of carbon nanotubes? A Guide to Methods and Optimization

- What is the difference between sputtering and ion beam deposition? Precision vs. Throughput for Your Thin Films