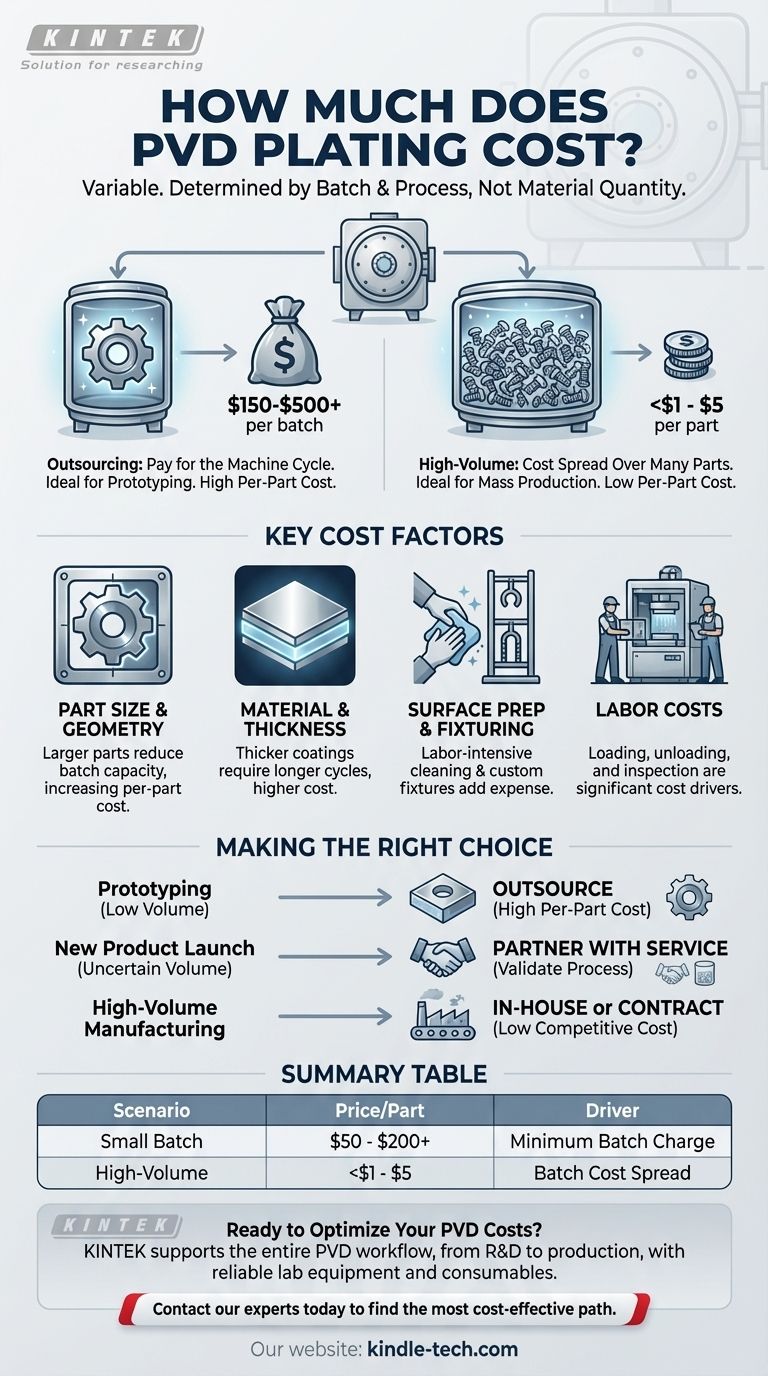

The cost of PVD (Physical Vapor Deposition) plating is not a fixed number but a highly variable figure, ranging from less than a dollar to over $100 per part. This price is rarely determined by the coating material itself, but rather by the method of processing, the volume of parts, and the complexity of the job. For small jobs, you pay for the machine's time; for large jobs, you pay for the space your parts occupy.

The central factor determining PVD cost is whether you are paying a high per-part price for a small, outsourced batch or achieving a low per-part price through high-volume production, either in-house or with a dedicated vendor. The cost is driven by machine cycle time, not the quantity of coating material used.

The Core Cost Driver: Batch vs. Per-Piece

Understanding PVD pricing requires a shift in thinking from a per-piece model to a batch processing model. PVD coating occurs inside a sealed vacuum chamber, and the primary cost is associated with running a single coating cycle, or "batch," regardless of how many parts are inside.

Outsourcing to a Coating Service

When you send a small number of parts to a PVD service, you are essentially renting an entire machine cycle. These services have minimum lot charges, often ranging from $150 to $500 or more.

If your single part is the only one in a batch that costs $200 to run, your cost for that part is $200. This model is ideal for prototypes, custom work, or low-volume runs where the high per-piece cost is acceptable.

High-Volume Processing (In-House or Vendor)

For mass production, the goal is to fit as many parts as possible into a single batch. If that same $200 machine cycle can hold 400 small parts, the cost drops to just $0.50 per part.

Bringing PVD equipment in-house amplifies this effect. While the initial capital investment is significant, it can drastically reduce the cost per part to mere cents for manufacturers with consistent, high-volume needs.

Key Factors That Influence PVD Pricing

Beyond the batch model, several variables directly impact the final quote you will receive from a PVD service provider.

Part Size and Geometry

The physical dimensions and shape of your part are critical. The more space a part takes up, the fewer units can fit into a single batch, which directly increases the cost allocated to each part.

Coating Material and Thickness

Different coatings (like TiN, CrN, or DLC) have different deposition rates and process parameters. A thicker coating requires a longer cycle time in the vacuum chamber, which increases the cost of running the batch.

Substrate Material and Preparation

The cost of PVD is not just the coating process itself. Parts must be meticulously cleaned and prepared before entering the chamber. Some materials require more extensive—and therefore more expensive—surface preparation to ensure proper coating adhesion.

Fixturing and Racking

Each part must be held by a custom or specialized fixture inside the chamber to ensure uniform coating. Complex parts may require custom-designed racking, adding engineering and labor costs to the job, especially for the initial run.

Understanding the Trade-offs

The extreme variability in pricing comes with clear trade-offs that you must consider for your specific application.

The High Cost of Low Volume

Outsourcing a handful of items will always be expensive on a per-part basis due to the minimum lot charges. It is economically inefficient to run a large, energy-intensive machine for just a few pieces.

The Capital Expense of In-House Systems

While bringing PVD in-house offers the lowest per-part cost, the equipment represents a major capital investment, often costing hundreds of thousands of dollars. This is only justifiable for companies with a very high and consistent volume of parts to coat.

The "Hidden" Costs of Labor

The PVD process is labor-intensive. Costs for loading and unloading the chamber, pre-cleaning and surface preparation, and post-coating quality inspection are all factored into the final price. These steps are often more time-consuming than the coating cycle itself.

Making the Right Choice for Your Goal

Your decision should be based entirely on the goals and scale of your project.

- If your primary focus is prototyping or custom work: Outsource to a PVD service and plan for minimum batch charges, which will result in a high cost per individual part.

- If your primary focus is launching a new product with uncertain volume: Begin by partnering with a coating service to validate the process and establish a supply chain before considering a major capital investment.

- If your primary focus is high-volume manufacturing: Bringing the process in-house or negotiating a high-volume contract with a service vendor is the only way to achieve a low, competitive per-part cost.

By understanding that PVD is priced by the batch, not by the piece, you can make the most cost-effective decision for your manufacturing needs.

Summary Table:

| Cost Scenario | Typical Price Per Part | Key Driver |

|---|---|---|

| Prototype / Small Batch (Outsourced) | $50 - $200+ | Minimum batch charge ($150-$500) for a full machine cycle. |

| High-Volume Production (Outsourced or In-House) | <$1 - $5 | Cost of a batch is spread across hundreds or thousands of parts. |

| Primary Cost Factors | Impact on Price | Notes |

| Part Size & Geometry | High | Larger/complex parts take up more chamber space, reducing parts per batch. |

| Coating Material & Thickness | Medium | Thicker coatings or specific materials require longer cycle times. |

| Surface Preparation & Fixturing | Medium to High | Complex cleaning or custom racking adds engineering and labor costs. |

Ready to Optimize Your PVD Plating Costs?

Whether you are developing a prototype or scaling up for mass production, choosing the right PVD processing method is critical for managing your budget and ensuring quality.

KINTEK specializes in providing lab equipment and consumables that support the entire PVD workflow, from R&D to final production. Our expertise can help you:

- Validate your coating process with reliable laboratory equipment before committing to large-scale production.

- Achieve consistent, high-quality results with the right consumables and preparation materials.

- Scale your operations efficiently with solutions tailored to your production volume.

Let's discuss your project's specific needs. Contact our experts today to find the most cost-effective path for your PVD plating requirements.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition