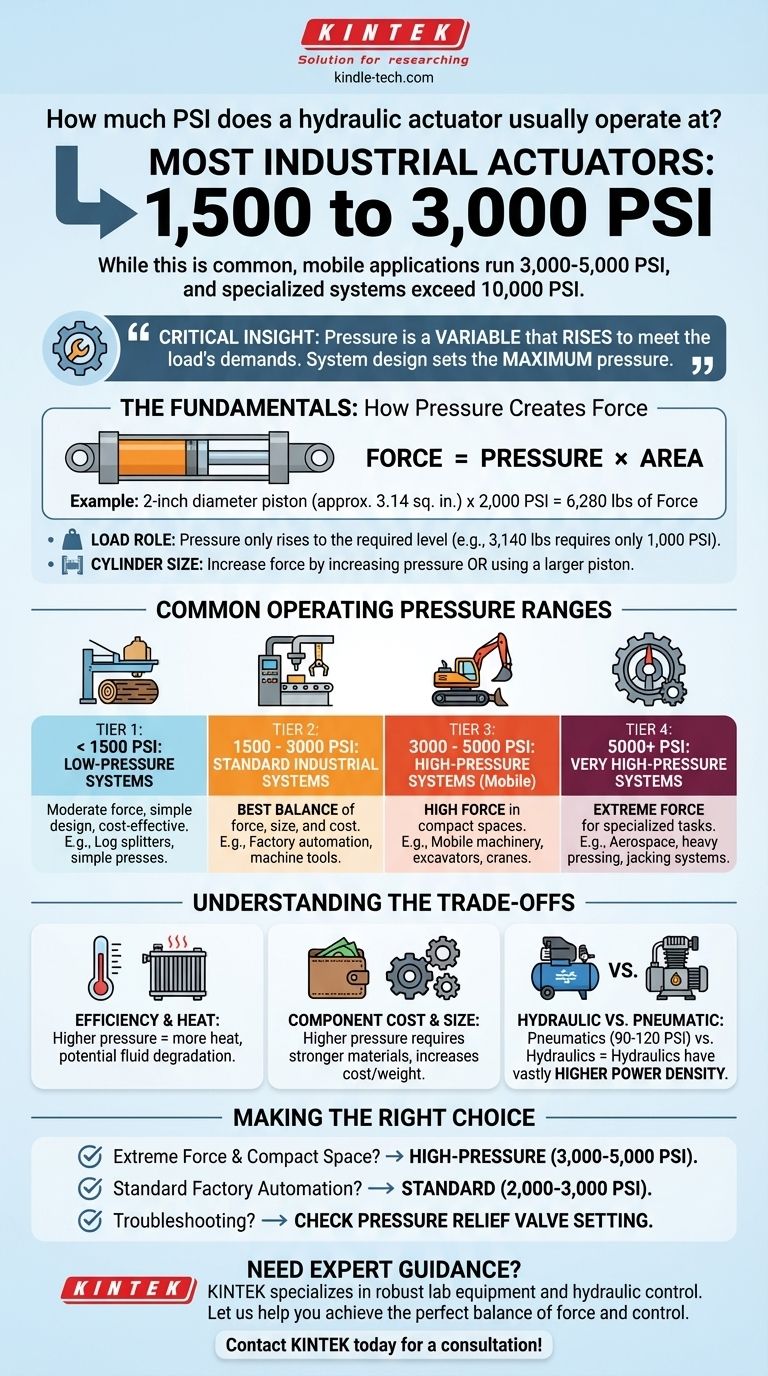

In practice, most industrial hydraulic actuators operate between 1,500 and 3,000 PSI. While this is the most common range, it's a small part of a much larger picture. Mobile applications like excavators frequently run at 3,000 to 5,000 PSI, and specialized systems in heavy pressing or aerospace can exceed 10,000 PSI.

The critical insight is that a hydraulic system doesn't have one single operating pressure. Pressure is a variable that rises to meet the demands of the load. The system's design simply sets the maximum pressure it can safely handle.

The Fundamentals: How Pressure Creates Force

To truly understand operating pressure, you must first understand the relationship between pressure, area, and force. This is the foundational principle of all hydraulic systems.

The Core Formula: Force = Pressure x Area

This simple equation governs everything. The output force of an actuator is the result of the system's pressure acting on the surface area of the actuator's piston.

For example, a cylinder with a 2-inch diameter piston has a surface area of approximately 3.14 square inches. If you apply 2,000 PSI of fluid pressure, it will generate 6,280 pounds of force (2,000 PSI x 3.14 in²).

The Role of the Load

A hydraulic system only generates the pressure required to move the load. If the actuator from the example above only needs to produce 3,140 pounds of force, the system pressure will only rise to 1,000 PSI, even if it's capable of 3,000 PSI. Pressure is resistance-driven.

The Role of Cylinder Size

You can achieve the same force with different combinations of pressure and area. Need more force? You can either increase the system pressure or use an actuator with a larger piston diameter. This is a central design decision.

Common Operating Pressure Ranges

Different applications have evolved to favor different pressure ranges based on their unique requirements for force, speed, size, and efficiency.

Low-Pressure Systems (< 1500 PSI)

These systems are common for applications where force requirements are moderate and simplicity is key. You'll find them in log splitters, simple hydraulic presses, and some agricultural implements. Components are generally less expensive and more forgiving.

Standard Industrial Systems (1500 - 3000 PSI)

This is the sweet spot for most factory automation, machine tools, and general industrial machinery. It provides an excellent balance of force, component size, and cost. Most standard pumps, valves, and actuators are designed for this range, particularly the nominal 3,000 PSI rating.

High-Pressure Systems (3000 - 5000 PSI)

This range is dominated by mobile machinery like excavators, bulldozers, and cranes. In these applications, space is at a premium. Higher pressure allows for smaller actuators and components to generate immense force, a critical factor for compact and powerful equipment design.

Very High-Pressure Systems (5,000+ PSI)

These are specialized, high-performance systems. Applications include large hydraulic presses for metal forming, aircraft landing gear and control surfaces, and high-capacity jacking systems. Components for this range are expensive, require meticulous maintenance, and have significant safety considerations.

Understanding the Trade-offs

Choosing a pressure range is a balancing act. Simply using the highest pressure possible is rarely the best solution.

Efficiency and Heat

Every time hydraulic fluid is pressurized, energy is used. If a system is designed for 5,000 PSI but routinely operates at 1,500 PSI, it can be inefficient. Furthermore, pressure drops across valves and orifices generate heat, and higher pressures can lead to more significant heat generation, which degrades fluid and damages seals.

Component Cost and Size

Higher pressure ratings demand stronger materials and more robust construction. A hose, valve, or pump rated for 5,000 PSI is significantly more expensive and often heavier than its 3,000 PSI counterpart. The entire system must be designed to withstand the maximum pressure.

The Hydraulic vs. Pneumatic Distinction

It's helpful to compare these pressures to pneumatic systems, which typically operate between 90 and 120 PSI. This massive difference in pressure is why hydraulics can generate enormous force from relatively small actuators, giving it a much higher power density.

Making the Right Choice for Your Application

The "correct" pressure is determined by your primary goal. Use your system's maximum pressure rating as a ceiling, not a target.

- If your primary focus is extreme force in a compact space: A high-pressure system (3,000-5,000 PSI) is likely necessary, as seen in mobile construction equipment.

- If your primary focus is standard factory automation or machine building: Designing around a nominal 2,000-3,000 PSI system provides the best balance of performance, component availability, and cost.

- If you are troubleshooting an existing system: The most important number is the pressure relief valve setting. This tells you the system's maximum designed pressure, which is the ultimate limit for safe operation.

Ultimately, pressure is the tool an engineer uses to efficiently and safely generate the precise force needed for the task at hand.

Summary Table:

| Application Type | Typical Operating Pressure Range (PSI) | Key Characteristics |

|---|---|---|

| Low-Pressure Systems | < 1,500 PSI | Moderate force, simple design, cost-effective components. |

| Standard Industrial Systems | 1,500 - 3,000 PSI | Best balance of force, component size, availability, and cost. |

| High-Pressure Systems (Mobile) | 3,000 - 5,000 PSI | High force in compact spaces; common in excavators and cranes. |

| Very High-Pressure Systems | 5,000+ PSI | Extreme force for specialized applications like aerospace and heavy pressing. |

Need expert guidance on hydraulic systems for your lab or production equipment?

Choosing the right pressure range is critical for the performance, safety, and efficiency of your machinery. The team at KINTEK specializes in providing robust lab equipment and consumables, including systems that rely on precise hydraulic control. We can help you select or maintain equipment that operates optimally within the correct pressure parameters for your specific application.

Let us help you achieve the perfect balance of force and control.

Contact KINTEK today for a consultation on your laboratory equipment needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.