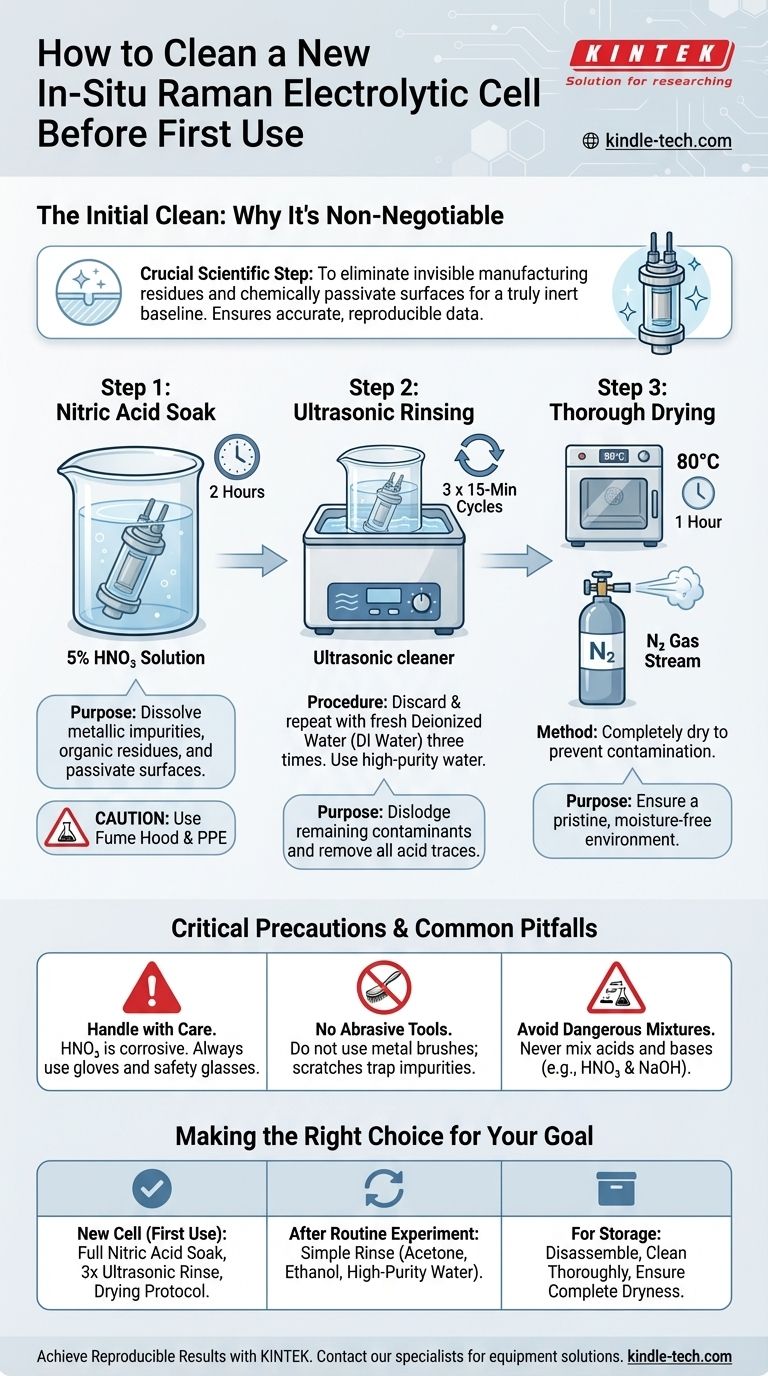

To properly clean a new in-situ Raman electrolytic cell, you must perform a specific multi-step chemical and physical cleaning process. This involves soaking the cell body in a 5% nitric acid (HNO₃) solution for two hours, followed by three separate 15-minute ultrasonic cleanings in deionized water, and finally drying it in an 80°C oven or with nitrogen gas.

The goal of this initial, rigorous cleaning is not merely to remove visible dust. It is a critical scientific step to eliminate invisible manufacturing residues and chemically passivate the cell surfaces, ensuring your experiments start from a truly inert and uncontaminated baseline.

The Rationale: Why Initial Cleaning is Non-Negotiable

The preparation of a new cell is foundational to the quality of your data. Skipping or rushing this process introduces variables that can compromise your results.

Removing Manufacturing Residues

A new cell can have trace contaminants from its production, such as machine oils, mold-release agents, or surface impurities on PTFE components. These substances can interfere with your electrochemical reactions or produce confounding signals in your Raman spectra.

Chemical Passivation

Soaking in nitric acid does more than just clean. It performs a crucial task called passivation, where it removes more reactive trace metals and contaminants from the cell's surfaces, creating a less reactive, more stable foundation for your experiment.

Ensuring a Pristine Electrochemical Environment

The ultimate goal is to create an environment where the only reactions occurring are the ones you intend to study. A thoroughly cleaned cell prevents unwanted side reactions, ensures accurate measurements, and leads to clean, reproducible spectroscopic data.

The Step-by-Step Cleaning Protocol for a New Cell

Follow this exact procedure before a new cell's first use. Each step is designed to systematically remove a different type of potential contaminant.

Step 1: Nitric Acid Soak

Place the cell body in a 5% HNO₃ solution and allow it to soak for 2 hours. This acid treatment is aggressive enough to dissolve metallic impurities and organic residues without damaging the cell materials.

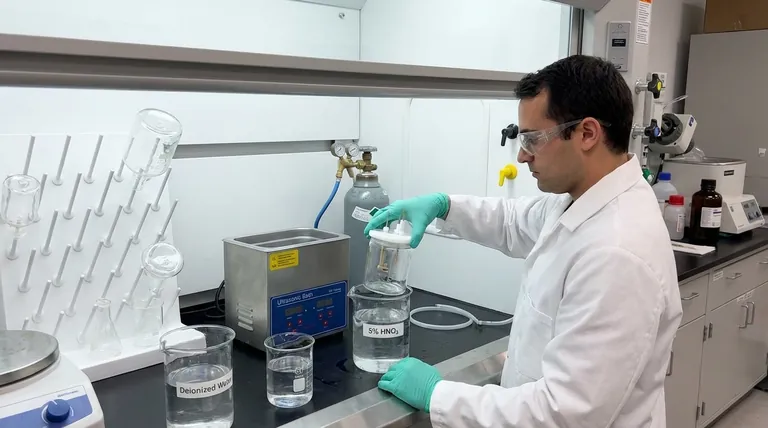

Step 2: Ultrasonic Rinsing

After the acid soak, move the cell to a beaker of deionized water and place it in an ultrasonic bath for 15 minutes. This process uses high-frequency sound waves to dislodge any remaining contaminants.

Critically, you must discard the water and repeat this ultrasonic rinse two more times with fresh deionized water, for a total of three cycles. Using high-purity water (e.g., 18.2 MΩ·cm) is ideal for the final rinses.

Step 3: Thorough Drying

Finally, the cell must be completely dry. You can either place it in an oven at 80°C for 1 hour or blow it dry with a stream of pure nitrogen gas. The nitrogen method is often preferred as it is faster and avoids prolonged heat exposure.

Critical Precautions and Common Pitfalls

Proper cleaning requires a focus on safety and technique. Errors can be dangerous or damage the equipment.

Handle Chemicals with Care

Always work in a well-ventilated fume hood when using nitric acid. Wear appropriate personal protective equipment (PPE), including gloves and safety glasses, as HNO₃ is highly corrosive.

Never Use Abrasive Tools

Do not use metal brushes or other hard implements to scrub the inside of the cell. These can create microscopic scratches on the surfaces that trap impurities and alter electrochemical behavior.

Avoid Dangerous Chemical Mixtures

Never mix acids and bases (e.g., nitric acid and sodium hydroxide). This can cause a violent and dangerous exothermic reaction. Always complete one chemical cleaning step and rinse thoroughly before considering another.

Ensure Complete Removal of Cleaning Agents

The thorough, multi-stage rinsing process is essential. Any residual nitric acid or other cleaning agents left in the cell will become a major contaminant in your experiment.

Making the Right Choice for Your Goal

The cleaning protocol you use depends entirely on the state of the cell. Using the correct procedure ensures both data integrity and the longevity of your equipment.

- If you are preparing a brand-new cell for its first use: You must follow the full nitric acid soak, ultrasonic rinse, and drying protocol to establish a clean, passive baseline.

- If you are cleaning a cell after a routine experiment: A simpler rinse with acetone, then ethanol, and finally high-purity water is typically sufficient to remove fresh electrolyte and reaction products.

- If you are preparing a cell for long-term storage: Disassemble the components, clean them thoroughly, and ensure every part is completely dry before storing it in a protected, moisture-free environment.

A meticulously prepared cell is the foundation of trustworthy and reproducible electrochemical data.

Summary Table:

| Step | Procedure | Purpose |

|---|---|---|

| 1. Acid Soak | Soak in 5% HNO₃ for 2 hours | Remove manufacturing residues & passivate surfaces |

| 2. Rinse | 3x 15-min ultrasonic cleans in deionized water | Remove all acid and dislodged contaminants |

| 3. Dry | Oven (80°C) or nitrogen gas stream | Ensure a completely dry, contaminant-free environment |

Achieve Reproducible Electrochemical Results with KINTEK

Your research demands precision. A properly cleaned in-situ Raman cell is the foundation of accurate, contamination-free data. KINTEK specializes in high-quality lab equipment and consumables designed for reliability and ease of maintenance, directly supporting the rigorous protocols outlined above.

Let our expertise help you maintain the highest standards in your laboratory. Contact our specialists today to find the perfect equipment solutions for your electrochemical and spectroscopic needs.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- H Type Electrolytic Cell Triple Electrochemical Cell

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments

- What are the standard components of the five-port water bath electrolytic cell? Master the Precision Instrument for Electrochemical Analysis

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained