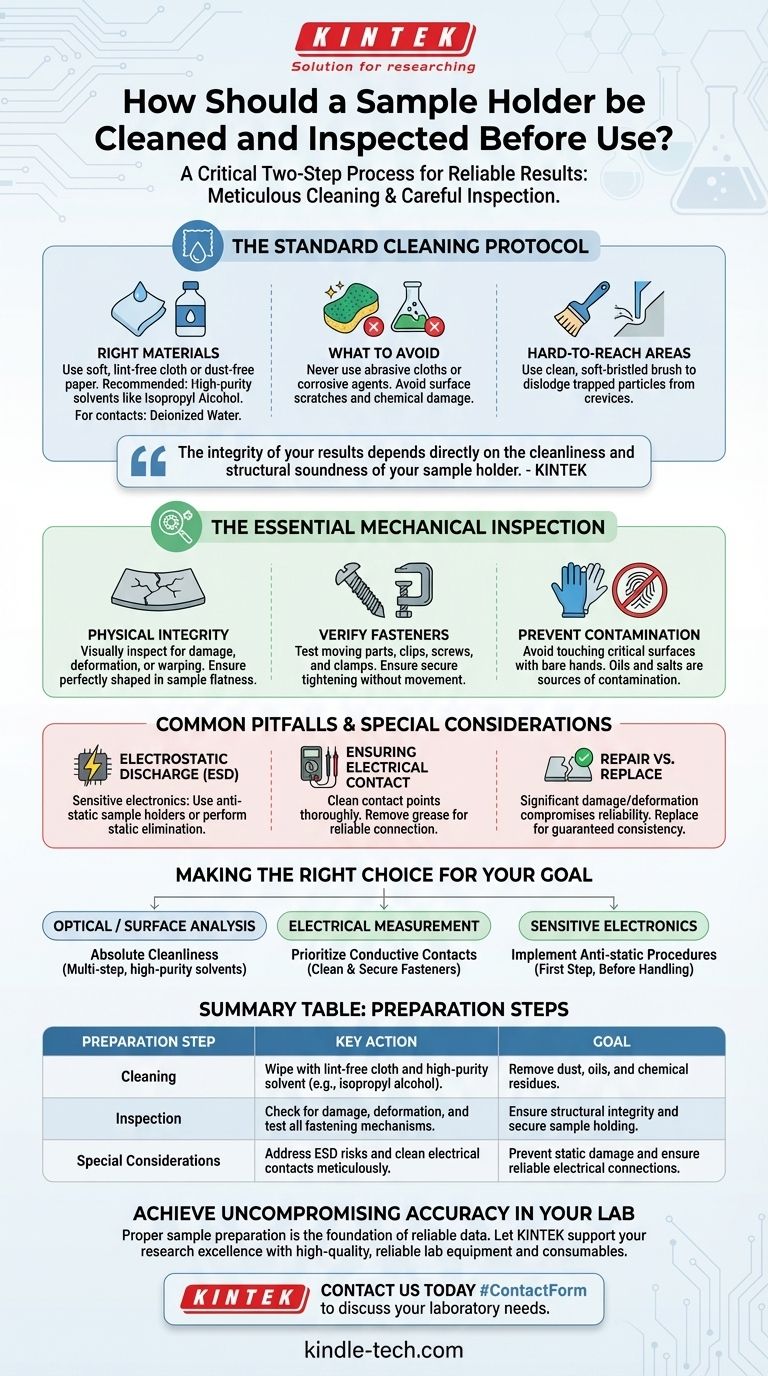

Properly preparing a sample holder is a critical two-step process that involves a meticulous cleaning to remove contaminants followed by a careful inspection for physical integrity. The surface should be wiped with a clean, soft, lint-free cloth dampened with a suitable solvent like alcohol. At the same time, the holder must be inspected for any damage, deformation, or missing parts to ensure it can secure the sample reliably.

The integrity of your results depends directly on the cleanliness and structural soundness of your sample holder. A contaminated or damaged holder introduces variables that can compromise or entirely invalidate an entire experiment.

The Standard Cleaning Protocol

A pristine sample holder is the first step toward reliable data. The goal is to remove any foreign material that could interfere with your analysis, whether it's dust, oil, or chemical residue.

Choosing the Right Materials

Use a soft, lint-free cloth or dust-free paper for wiping. This prevents scratching the holder's surface or leaving behind new fibrous contaminants.

For a cleaning agent, a high-purity solvent like isopropyl alcohol is generally effective for removing oils and common impurities. In cases involving electrical contacts, deionized water can be used to rinse conductive sheets.

What to Avoid

Never use abrasive cloths or corrosive cleaning agents. These can create microscopic scratches on the surface or cause chemical reactions, permanently damaging the holder and potentially altering your experimental results.

Addressing Hard-to-Reach Areas

If the sample holder has intricate features like crevices or grooves, a simple wipe may not be sufficient. Use a clean, soft-bristled brush to gently dislodge any trapped particles or debris.

The Essential Mechanical Inspection

A clean but faulty holder is just as problematic as a dirty one. The mechanical inspection ensures the holder can perform its primary function: to hold the sample securely and in the correct position.

Checking for Physical Integrity

Visually inspect the entire holder for any signs of damage, deformation, or warping. A holder that is not perfectly shaped may not hold the sample flat or in the correct orientation, leading to measurement errors.

Verifying Fastening Mechanisms

Test any moving parts. Ensure that clips open and close properly and that all fastening components, such as screws or clamps, are in good condition. They must be able to tighten sufficiently to hold the test sample without any movement.

Preventing Contamination from Handling

Throughout the cleaning and inspection process, avoid touching the critical surfaces of the holder or the sample with your bare hands. Oils and salts from your skin are significant sources of contamination.

Common Pitfalls and Special Considerations

Beyond the standard procedure, certain environments and sample types require additional precautions to prevent catastrophic failures or subtle inaccuracies.

Electrostatic Discharge (ESD)

In experiments sensitive to static electricity, the holder itself can pose a risk. An electrostatic discharge can instantly destroy sensitive electronic samples.

To mitigate this, use a dedicated anti-static sample holder or perform a static elimination process on the holder before bringing it near the sample.

Ensuring Electrical Contact

For experiments involving electrical measurements, the cleanliness of contact points is paramount. Any grease or impurity on a conductive sheet can create an insulating barrier, preventing a reliable electrical connection to the sample.

When to Repair vs. Replace

If you discover an issue, you must decide whether to repair or replace the holder. Loose screws can be tightened, but any significant damage or deformation compromises the holder's reliability. In these cases, replacement is the only way to guarantee consistent results.

Making the Right Choice for Your Goal

Your specific experimental needs should guide the focus of your preparation protocol.

- If your primary focus is optical or surface analysis: Absolute cleanliness is paramount; concentrate on a multi-step cleaning process with high-purity solvents to ensure no residue remains.

- If your primary focus is electrical measurement: Prioritize the cleanliness of conductive contact points and verify the security of all mechanical fastening components.

- If you are working with sensitive electronics: Implement anti-static procedures as the very first step, before any other cleaning or handling takes place.

This disciplined pre-use check is the foundation for reliable and repeatable outcomes.

Summary Table:

| Preparation Step | Key Action | Goal |

|---|---|---|

| Cleaning | Wipe with lint-free cloth and high-purity solvent (e.g., isopropyl alcohol). | Remove dust, oils, and chemical residues. |

| Inspection | Check for damage, deformation, and test all fastening mechanisms. | Ensure structural integrity and secure sample holding. |

| Special Considerations | Address ESD risks and clean electrical contacts meticulously. | Prevent static damage and ensure reliable electrical connections. |

Achieve Uncompromising Accuracy in Your Lab

Proper sample preparation is the foundation of reliable data. KINTEK understands that the integrity of your results depends on the quality and cleanliness of your lab equipment.

Let us support your research excellence. We specialize in providing high-quality, reliable lab equipment and consumables, including sample holders designed for precision and durability.

Contact us today to find the perfect tools for your specific application—from optical analysis to sensitive electrical measurements. Our experts are ready to help you ensure every experiment starts with a solid foundation.

#ContactForm to discuss your laboratory needs and enhance your workflow reliability.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Button Battery Case for Battery Lab Applications

People Also Ask

- What are the specific storage requirements for a sample holder? Protect Your Lab's Critical Assets

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool