After an experiment, handling the contents of an electrolytic cell involves a clear, safety-oriented sequence. First, you must always turn off the power supply before disconnecting the cell. The contents are then removed, with products intended for analysis being properly stored, while waste electrolytes are treated according to their chemical properties and environmental regulations before disposal.

Your post-experiment procedure is not just cleanup; it is a critical phase of the scientific process that ensures operator safety, protects the environment, and preserves the integrity of your equipment for future work.

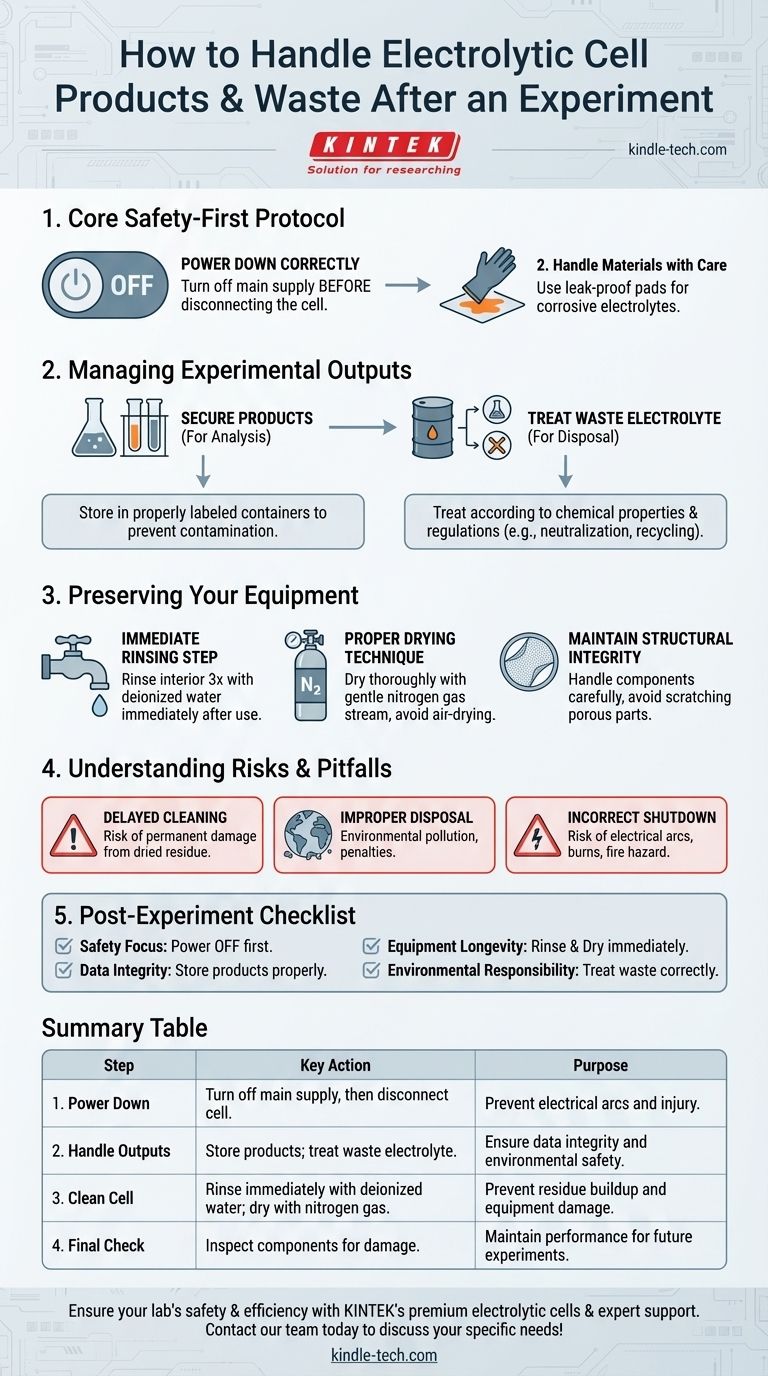

The Core Safety-First Protocol

Before you handle any materials, you must ensure the system is in a safe, de-energized state.

Power Down Correctly

The single most important first step is to turn off the main power supply.

Only after the power is confirmed to be off should you proceed to disconnect the electrolytic cell from the power source. Following this sequence prevents the risk of electrical arcs, which can cause injury and damage equipment.

Handle Materials with Care

If you used a corrosive electrolyte, it should have been placed on a leak-proof pad during the experiment. This precaution extends to the cleanup phase, where careful handling is necessary to prevent spills and chemical burns.

Managing Experimental Outputs

Once the cell is safely disconnected, you must manage the products and the remaining electrolyte.

Secure Your Products

If a product generated during the experiment requires further processing or analysis, it must be removed and stored in a suitable, properly labeled container. This prevents contamination or degradation of your results.

Treat the Waste Electrolyte

The remaining waste liquid, or electrolyte, cannot simply be poured down the drain. It must be treated according to its specific chemical properties and local environmental protection requirements.

Common treatment methods include neutralization, chemical deactivation, or collection for specialized recycling or disposal services to prevent pollution.

Preserving Your Equipment

Proper cleaning and handling are essential for maintaining the performance and extending the life of the electrolytic cell.

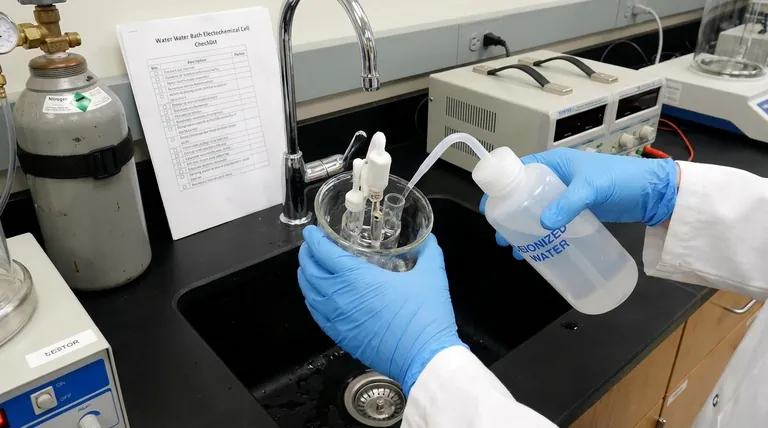

The Immediate Rinsing Step

For cells used with aqueous solutions, you must act quickly. After pouring out the electrolyte, immediately rinse the cell's interior at least three times with deionized water.

This prevents residual electrolytes from drying and solidifying into a residue that is difficult to remove and can damage the cell's internal surfaces.

Proper Drying Technique

After rinsing, do not let the cell air-dry, as this can leave water stains. Instead, dry the interior thoroughly with a gentle stream of nitrogen gas or another inert gas.

Maintain Structural Integrity

Throughout the disassembly and cleaning process, handle the cell and its components with care. Avoid scratching or compressing sensitive parts, such as porous membranes or electrodes, as this can permanently impair their performance.

Understanding the Risks and Pitfalls

Mistakes in the post-experiment phase can have significant consequences for safety, your results, and your budget.

The Risk of Delayed Cleaning

Procrastinating on cleaning is the most common error. When residual electrolytes dry, they can form a crystalline crust that is nearly impossible to remove without damaging the cell's delicate internal structures. This can ruin an expensive piece of equipment.

The Consequence of Improper Disposal

Simply disposing of electrolytes without proper treatment is a serious issue. It leads to environmental pollution and may violate institutional safety protocols and local regulations, carrying significant penalties.

The Danger of Incorrect Shutdown

Failing to turn off the power supply before disconnecting the cell is a critical safety failure. It creates a very real risk of generating an electrical arc, which can cause severe burns and create a fire hazard.

A Checklist for Post-Experiment Success

Use this checklist to ensure your protocol is safe, responsible, and effective.

- If your primary focus is safety: The absolute first step is always to turn off the power supply before disconnecting any wires.

- If your primary focus is data integrity: Immediately and properly store your collected products in sealed, labeled containers to prevent degradation or contamination.

- If your primary focus is equipment longevity: Clean the cell immediately with deionized water and dry it with nitrogen gas to prevent permanent residue buildup and damage.

- If your primary focus is environmental responsibility: Always treat waste electrolytes according to their specific chemical properties and local disposal regulations.

A disciplined and consistent post-experiment protocol is the mark of a careful and professional scientific practice.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Power Down | Turn off main supply, then disconnect cell. | Prevent electrical arcs and injury. |

| 2. Handle Outputs | Store products for analysis; treat waste electrolyte. | Ensure data integrity and environmental safety. |

| 3. Clean Cell | Rinse immediately with deionized water; dry with nitrogen gas. | Prevent residue buildup and equipment damage. |

| 4. Final Check | Inspect components for damage before storage. | Maintain performance for future experiments. |

Ensure your lab's safety and efficiency with KINTEK's premium electrolytic cells and expert support. Proper handling is crucial, and having reliable equipment is the first step. KINTEK specializes in durable, high-performance lab equipment and consumables designed for easy maintenance and long-term use. Let our experts help you select the right tools and establish best practices for your laboratory. Contact our team today to discuss your specific needs and enhance your experimental workflows!

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup