To properly maintain a muffle furnace, you must implement a routine that includes environmental control, pre- and post-use inspections, and specific operational protocols. This involves ensuring the furnace is in a dry, clean environment, baking it before use if it has been inactive, keeping the chamber clean, and following correct heating and cooling procedures to prevent damage.

The core principle of muffle furnace maintenance is not just cleaning, but proactive management. Effective care treats the furnace as a precise instrument, where its operating environment, internal cleanliness, and usage cycles are all critical factors in ensuring its long-term safety, accuracy, and reliability.

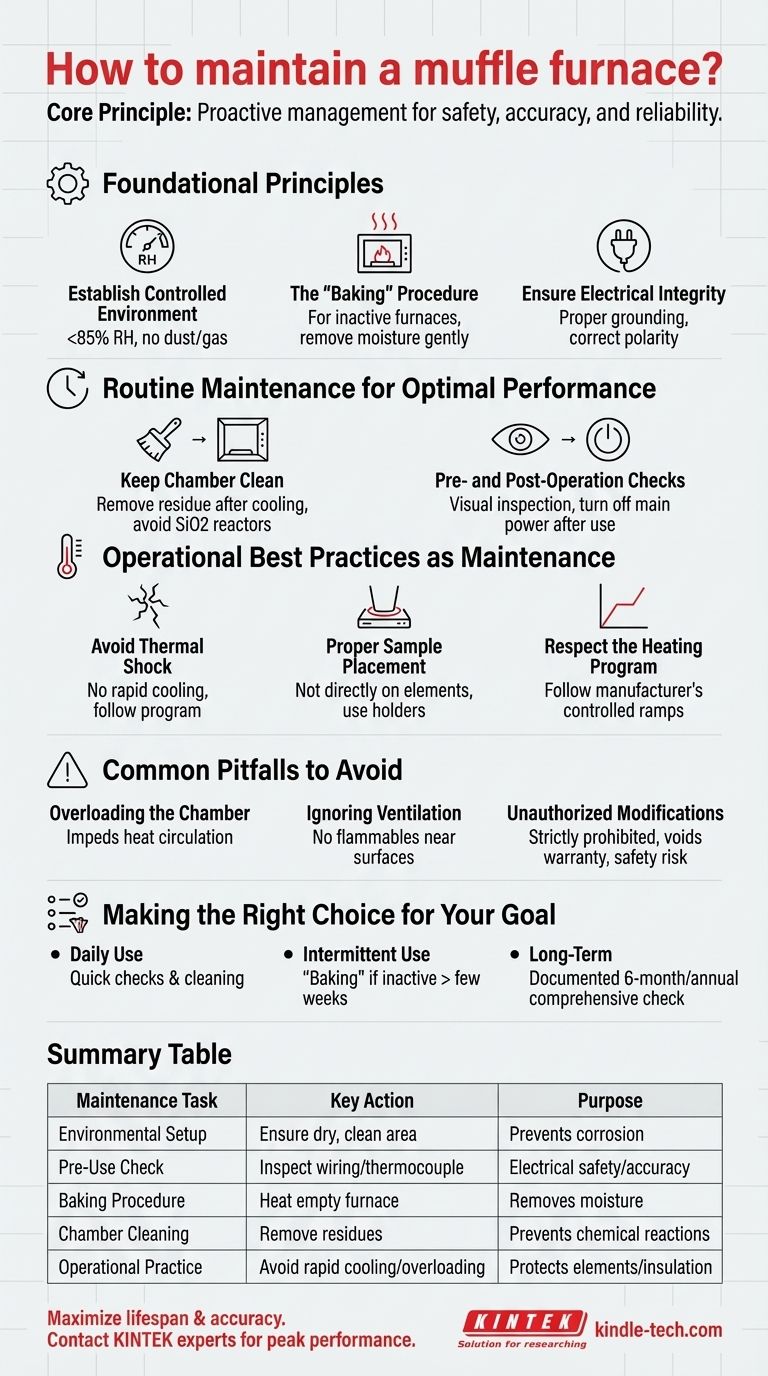

Foundational Principles of Furnace Care

Proper maintenance begins before you even turn the furnace on. The surrounding environment and initial setup are fundamental to the equipment's health and performance.

Establish a Controlled Environment

Your furnace must operate in a specific environment to function correctly. The relative humidity should not exceed 85%.

The area must also be free of conductive dust, explosive gases, or corrosive gases that could damage the electrical components or the furnace chamber itself.

The "Baking" Procedure for Inactive Furnaces

If a furnace is being used for the first time or has been inactive for a long period, it must be baked. This process involves heating the empty furnace to a low temperature for a period to gently drive out any accumulated moisture.

This step is critical to prevent rapid steam generation within the refractory materials, which can cause cracking and compromise the insulation.

Ensure Electrical Integrity and Safety

Before any operation, confirm that the furnace and its controller are properly grounded. A dedicated power switch should be installed at the power line inlet for emergency shut-offs.

The thermocouple, which measures temperature, must be inserted correctly and connected to the controller with the correct polarity. Gaps around the thermocouple entry point should be filled with asbestos rope to prevent heat loss.

Routine Maintenance for Optimal Performance

Daily and periodic checks are essential for identifying potential issues before they become critical failures. This routine preserves the accuracy and extends the life of the furnace.

Keep the Chamber and Furnace Tube Clean

After the furnace has cooled, the internal chamber should be cleaned. Any residue from heated materials must be removed.

Crucially, you must not leave substances that react with the furnace lining (often containing SiO2) inside the chamber. Chemical reactions at high temperatures can permanently damage the refractory insulation.

Pre- and Post-Operation Checks

Before each use, perform a quick visual inspection of the furnace, controller, and wiring.

After every heating cycle is complete and the furnace has cooled, ensure the main power is turned off. This is a simple but vital step for safety and energy conservation.

Operational Best Practices as Maintenance

How you use the furnace is a primary form of maintenance. Adhering to correct operational procedures prevents the most common types of damage.

Avoid Thermal Shock

Never subject the furnace to rapid cooling. Abrupt temperature changes create immense stress on the ceramic and refractory components, leading to cracks and failure. Always allow the furnace to cool down gradually according to its specified program.

Proper Sample Placement

Never place samples or crucibles directly on the heating elements or the furnace floor if it contains embedded elements. This can cause localized overheating, create a fire risk, and damage both the sample and the furnace. Use appropriate ceramic plates or holders.

Respect the Heating Program

Always follow the manufacturer's recommended heating programs. These controlled ramps in temperature are designed to protect the heating elements and insulation from the stress of rapid expansion.

Common Pitfalls to Avoid

Mistakes in operation or maintenance can lead to costly repairs and unsafe conditions. Being aware of these common pitfalls is essential.

Overloading the Chamber

Do not overload the furnace. An overly dense load can impede proper heat circulation, leading to inaccurate and uneven heating of your samples.

Ignoring Ventilation and Surroundings

Ensure the furnace has adequate ventilation. Never place combustible or flammable materials anywhere near the furnace, as the exterior surfaces can reach high temperatures.

Unauthorized Modifications

Strictly prohibit any private modification to the furnace or its controller. Changes to the wiring, insulation, or programming can create significant safety hazards and will void any warranty.

Making the Right Choice for Your Goal

Your maintenance schedule should align with your usage patterns to ensure maximum reliability and safety.

- If your primary focus is daily, high-volume use: Perform a quick visual inspection before the first cycle and ensure the chamber is cleaned after the last cycle of the day.

- If your primary focus is intermittent, project-based use: Always perform the "baking" procedure to remove moisture if the furnace has been inactive for more than a few weeks.

- If your primary focus is long-term asset preservation: Implement a documented six-month or annual check of all wiring, connections, grounding, and the physical condition of the refractory lining.

Ultimately, treating your muffle furnace with a consistent and disciplined maintenance approach is the best way to guarantee its performance and safety for years to come.

Summary Table:

| Maintenance Task | Key Action | Purpose |

|---|---|---|

| Environmental Setup | Ensure dry, clean area (<85% humidity) | Prevents damage from moisture/corrosion |

| Pre-Use Check | Inspect wiring, grounding, and thermocouple | Guarantees electrical safety and accuracy |

| Baking Procedure | Heat empty furnace if inactive | Removes moisture to prevent refractory damage |

| Chamber Cleaning | Remove residues after cooling | Prevents chemical reactions with lining |

| Operational Practice | Avoid rapid cooling and overloading | Protects heating elements and insulation |

Maximize the lifespan and accuracy of your laboratory equipment. Proper maintenance is key to reliable results. KINTEK specializes in high-quality lab furnaces and consumables, providing the tools and support your laboratory needs for success. Contact our experts today to discuss your specific requirements and ensure your muffle furnace operates at peak performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the environmental impacts of metal processing? A Guide to Sustainability and Solutions

- What are the different types of laboratory furnaces? Find the Perfect Fit for Your Application

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure

- What are the advantages and disadvantages of a muffle furnace? A Guide to Precision Heating