Making a pressed pellet for XRF analysis is a systematic process designed to transform a raw sample into a stable, homogeneous disc suitable for measurement. The core procedure involves four distinct stages: grinding the sample into a fine powder, mixing it with a binder, loading the mixture into a die, and compressing it under high pressure.

The ultimate goal of creating a pressed pellet is not just to solidify the sample, but to produce a perfectly flat, dense, and homogeneous analytical surface. This meticulous preparation is the key to eliminating errors from particle size and density variations, ensuring your XRF data is both accurate and repeatable.

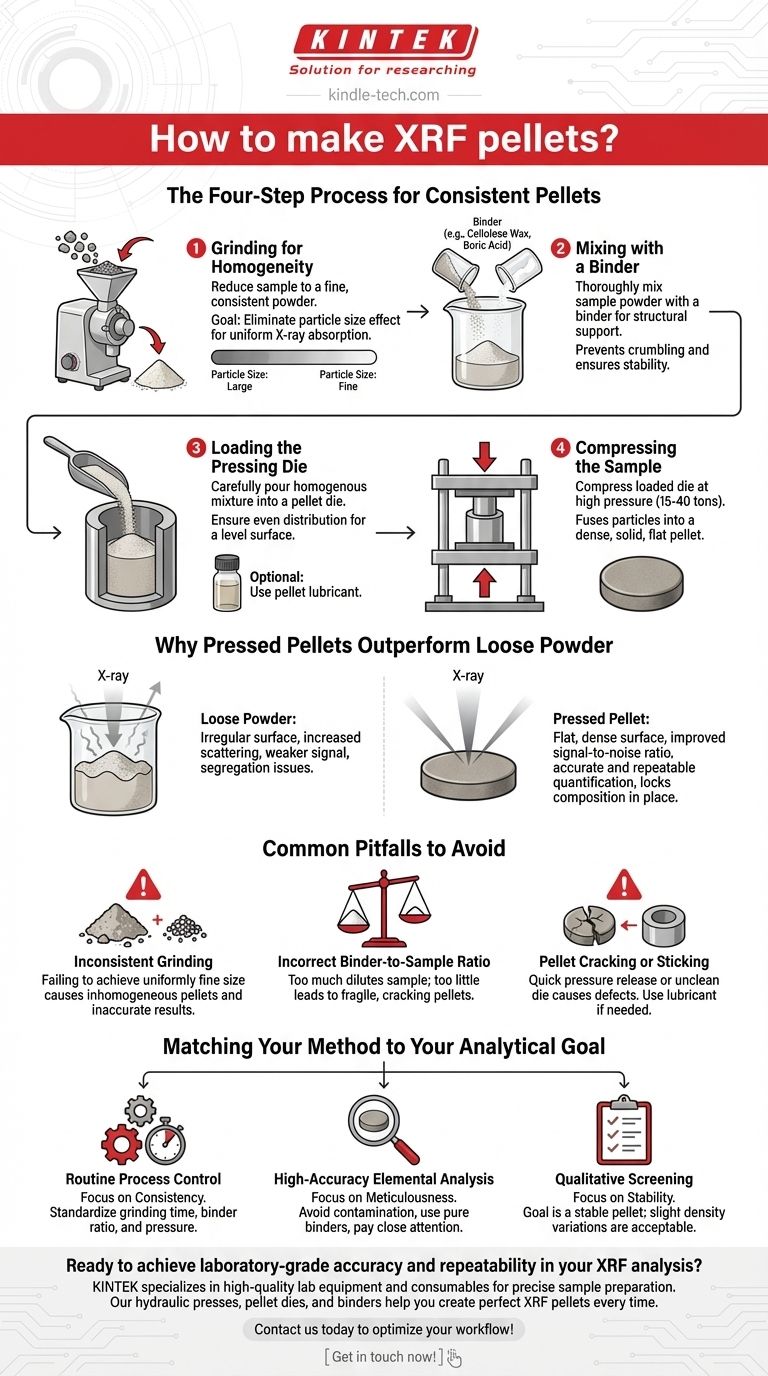

The Four-Step Process for Consistent Pellets

A successful XRF pellet provides the instrument with a uniform representation of the bulk sample. Each step in its creation is critical for achieving this uniformity.

Step 1: Grinding for Homogeneity

The first step is to reduce your sample to a fine, consistent powder, typically using a mill or grinder.

The goal is to eliminate the particle size effect, where larger particles can disproportionately absorb or scatter X-rays, skewing the final elemental composition data. A fine, flour-like consistency is ideal.

Step 2: Mixing with a Binder

Once ground, the sample powder is thoroughly mixed with a binder or a grinding aid.

Binders, such as cellulose wax or boric acid, serve as a structural support, helping the fine particles adhere to one another during pressing. This ensures the finished pellet is mechanically stable and won't crumble.

Step 3: Loading the Pressing Die

The homogenous mixture is then carefully poured into a cylindrical steel pellet die.

For best results, the powder should be distributed evenly to ensure a level surface. A small amount of pellet pressing lubricant can sometimes be applied to the die faces to prevent the finished pellet from sticking.

Step 4: Compressing the Sample

Finally, the loaded die is placed into a hydraulic press and compressed at high pressure.

Typical pressures range from 15 to 40 tons. This force compacts the powder, removes air voids, and fuses the particles and binder into a dense, solid pellet ready for analysis.

Why Pressed Pellets Outperform Loose Powder

While analyzing loose powder is faster, creating a pressed pellet provides significant analytical advantages that are essential for high-quality data.

Improved Signal-to-Noise Ratio

A dense, flat pellet surface minimizes X-ray scattering compared to the irregular surface of a loose powder.

This results in a stronger, clearer signal relative to the background noise. This is especially critical for accurately detecting lighter elements, which naturally produce a weaker fluorescent signal.

Accurate and Repeatable Quantification

Loose powders can suffer from segregation, where finer or denser particles settle to the bottom.

A pressed pellet locks the sample's composition in place, ensuring the instrument analyzes a truly representative surface every time. This removes discrepancies and leads to far more reliable quantitative results.

Common Pitfalls to Avoid

Even with the right equipment, several common issues can compromise pellet quality and, consequently, your analytical results.

Inconsistent Grinding

Failing to achieve a uniformly fine particle size is the most common source of error. An inhomogeneous powder will produce an inhomogeneous pellet, leading to inaccurate and non-repeatable measurements.

Incorrect Binder-to-Sample Ratio

Using too much binder can dilute your sample, making it difficult to detect trace elements. Using too little can result in a fragile pellet that cracks or crumbles after being ejected from the die.

Pellet Cracking or Sticking

Cracks often form if the pressure is applied or released too quickly. A pellet that sticks to the die surfaces may indicate that the die was not perfectly clean or that a lubricant was needed for that specific sample type.

Matching Your Method to Your Analytical Goal

The rigor of your pellet-making process should align with the required precision of your final data.

- If your primary focus is routine process control: Consistency is key. Standardize your grinding time, sample-to-binder ratio, and pressing pressure to ensure all pellets are made identically.

- If your primary focus is high-accuracy elemental analysis: Pay meticulous attention to avoiding contamination during grinding and ensure the binder material does not contain any elements you are trying to measure.

- If your primary focus is qualitative screening: The main goal is a stable pellet that won't contaminate the instrument. While still important, slight variations in density are less critical than for quantitative work.

Mastering this sample preparation technique is a fundamental step toward generating reliable and trustworthy XRF data.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Grinding | Achieve fine, uniform powder to eliminate particle size effects. |

| 2 | Mixing with Binder | Add structural support (e.g., cellulose wax) for pellet stability. |

| 3 | Loading the Die | Distribute mixture evenly in a steel die for a level surface. |

| 4 | Compressing | Apply high pressure (15-40 tons) to fuse particles into a dense disc. |

Ready to achieve laboratory-grade accuracy and repeatability in your XRF analysis?

KINTEK specializes in high-quality lab equipment and consumables for precise sample preparation. Our range of hydraulic presses, pellet dies, and binders are designed to help you create perfect XRF pellets every time, ensuring your data is reliable and contamination-free.

Contact us today to discuss your specific laboratory needs and let our experts help you optimize your sample preparation workflow. Get in touch now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- What are the safety precautions of a power press? Essential Guarding & LOTO Procedures

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions

- What are the safety issues with hydraulic systems? Understanding High-Pressure Fluid Injection and Stored Energy Risks

- What is the use of a hand press machine? Precision Force for Assembly, Stamping & Repair

- Why are hydraulic presses required when studying FATT50? Precision Tools for Grain Refinement & Impact Toughness

- Importance of Vacuum Infusion or Hydraulic Press in Bio-Based Composites? Unlock Superior Strength and Precision

- Why is a laboratory hydraulic press used to process perovskite powders? Ensure High-Density Sintering Results

- What are the safety rules for a hydraulic press? Essential Protocols for Operator and Machine Safety