In any system designed to move a heated or cooled liquid in a continuous circuit, you will almost certainly find a circulating pump at its heart. These devices are fundamental components in residential and commercial HVAC systems, solar thermal installations, and domestic hot water systems. Their primary role is not to increase pressure but to maintain the constant flow of fluid required for efficient heat transfer.

A circulating pump's purpose is not defined by the application, but by the system's architecture. They are specialized for closed-loop systems, where their only job is to overcome the friction within the pipes, making them exceptionally efficient at moving liquid to transfer energy.

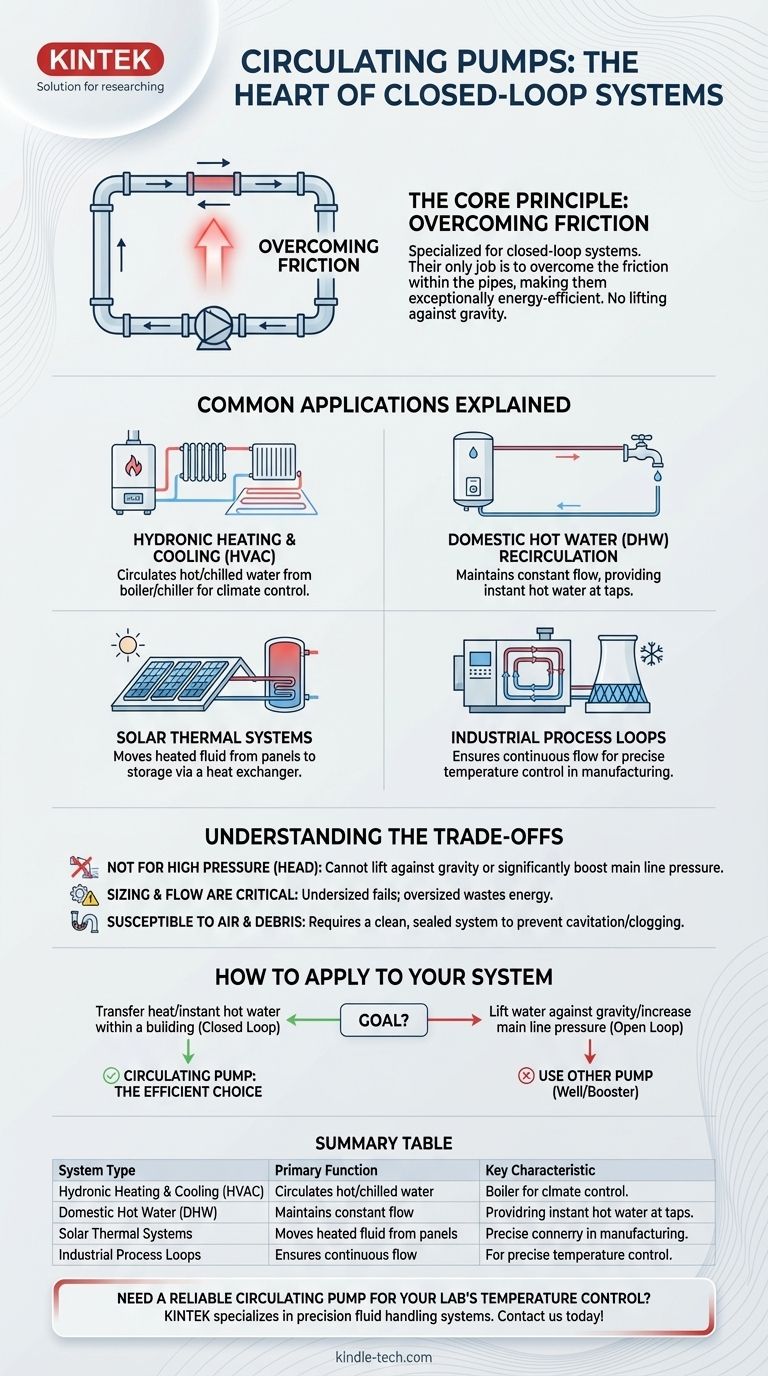

The Core Principle: Overcoming Friction in a Closed Loop

To understand where circulating pumps are used, you must first understand the type of work they are designed to do. They are not brute-force machines; they are masters of efficiency for a very specific task.

What Is a Closed-Loop System?

A closed-loop system is a plumbing circuit where the fluid returns to its starting point. Think of it like a circular racetrack. The water or other liquid leaves the source (like a boiler), travels through the pipes to deliver its energy, and then returns to the source to be reheated or re-chilled.

Because the fluid returns, the system is balanced. The weight of the water going down one side of the system helps push the water up the other side. This means the pump does not need to fight the force of gravity.

The Role of the Pump: Circulation vs. Lifting

The only force the pump must overcome is the friction created by the liquid rubbing against the inside of the pipes and fittings.

This is the critical difference between a circulating pump and a booster or well pump. A well pump must lift water hundreds of feet, working against immense pressure and gravity. A circulating pump simply gives the fluid in the closed loop the continuous "push" it needs to keep moving.

Why This Matters: Energy Efficiency

Because circulating pumps are designed for this low-pressure, high-flow task, they can operate with very small and highly efficient motors. Using a powerful booster pump for a simple heating loop would be like using a sledgehammer to tap in a nail—a massive waste of energy.

Common Applications Explained

The principle of the closed loop explains why circulating pumps are found in these specific applications.

Hydronic Heating & Cooling (HVAC)

This is the most common use. A pump circulates hot water from a boiler through a loop of pipes to radiators, baseboard heaters, or in-floor radiant tubing. In cooling systems, it circulates chilled water from a chiller to air handlers, which then blow cool air into a space.

Domestic Hot Water (DHW) Recirculation

In large homes or commercial buildings, it can take a long time for hot water to travel from the water heater to a distant faucet. A DHW recirculation system uses a small circulating pump on a dedicated loop to constantly and slowly move hot water through the pipes, ensuring it is always available near the tap.

Solar Thermal Systems

Solar thermal panels on a roof heat a fluid (often a glycol mixture). A circulating pump moves this hot fluid down to a storage tank, where a heat exchanger transfers the sun's energy into the building's water supply. The cooled fluid is then pumped back to the roof to be reheated.

Industrial Process Loops

Countless manufacturing processes require precise temperature control. Circulating pumps are used to move cooling fluids through machinery, circulate treated water, or move chemicals in a continuous process where maintaining flow is essential.

Understanding the Trade-offs

While highly effective, circulating pumps are a specialized tool with clear limitations.

Not Designed for High Pressure (Head)

A circulating pump cannot be used to lift water from a well or significantly boost the overall water pressure in a house. Attempting to use it for these tasks will result in failure, as it lacks the power to overcome high back-pressure.

Sizing and Flow Rate Are Critical

The pump must be correctly sized for the system's needs. An undersized pump will fail to move the fluid at the required rate, leading to poor heating or cooling. An oversized pump will waste electricity and can cause noise and erosion inside the pipes.

Susceptible to Air and Debris

Because they operate in a sealed system, circulating pumps are sensitive to problems within the loop. Air trapped in the pipes can stop circulation or damage the pump (a condition known as cavitation). Debris from corrosion can also clog the pump and impede its function.

How to Apply This to Your System

To determine if a circulating pump is the right component, focus on the primary goal of your fluid system.

- If your primary focus is transferring heat within a building (heating or cooling): A circulating pump is the standard and most efficient tool for moving hot or chilled water through radiators, air handlers, or radiant floor loops.

- If your primary focus is providing instant hot water at a distant faucet: A dedicated domestic hot water recirculation pump is the specific solution designed for this water-saving and convenience-oriented goal.

- If your primary focus is lifting water against gravity or increasing main line pressure: You need a different class of pump, such as a submersible well pump for a well or a booster pump for low city water pressure.

Ultimately, the choice is dictated by whether your system is open or closed; a circulating pump is the undisputed expert for the latter.

Summary Table:

| System Type | Primary Function | Key Characteristic |

|---|---|---|

| Hydronic Heating/Cooling (HVAC) | Circulates hot/chilled water for climate control | Uses a boiler or chiller in a closed loop |

| Domestic Hot Water (DHW) Recirculation | Provides instant hot water at taps | Maintains constant flow in a dedicated loop |

| Solar Thermal Systems | Moves heated fluid from panels to storage tank | Transfers solar energy via heat exchanger |

| Industrial Process Loops | Maintains precise temperature control in manufacturing | Ensures continuous flow for chemical or cooling processes |

Need a reliable circulating pump for your laboratory's temperature control system? KINTEK specializes in high-quality lab equipment and consumables, including precision fluid handling systems. Our circulating pumps ensure efficient heat transfer and consistent performance for your critical applications. Contact us today to find the perfect solution for your laboratory's unique needs!

Visual Guide

Related Products

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- Why is it necessary to configure a thermostatic water bath or ice bath during Ni–Cr–P electrodeposition?

- How does a high-temperature and high-pressure water circulation system control water chemistry for Alloy 690TT studies?

- How can I keep the temperature constant? Master Thermal Equilibrium for Ultimate Stability

- Why is a temperature control circulation system used in iron electrowinning? Maximize Energy & Deposit Quality

- What is the function of a water bath? Achieve Precise, Gentle Heating for Your Lab Samples

- Why is a high-precision cooling circulation system required for PEO? Master Thermal Stability for Superior Coatings

- How does a high-precision constant temperature circulator contribute to mineral dissolution kinetic studies?

- What role does a high-precision constant temperature circulating water bath play in AEM research? Stability & Control