In short, yes, all ceramics are breakable. While some modern ceramics are extraordinarily strong, no ceramic is unbreakable. Their reputation for strength comes from their exceptional hardness (resistance to scratching) and heat resistance, not from an ability to resist shattering from a sharp impact or drop.

The defining characteristic of ceramic is not its unbreakability, but its combination of extreme hardness and high brittleness. While it can resist scratches and wear better than most metals, it lacks the toughness to absorb impacts and will fracture, not bend, under sharp force.

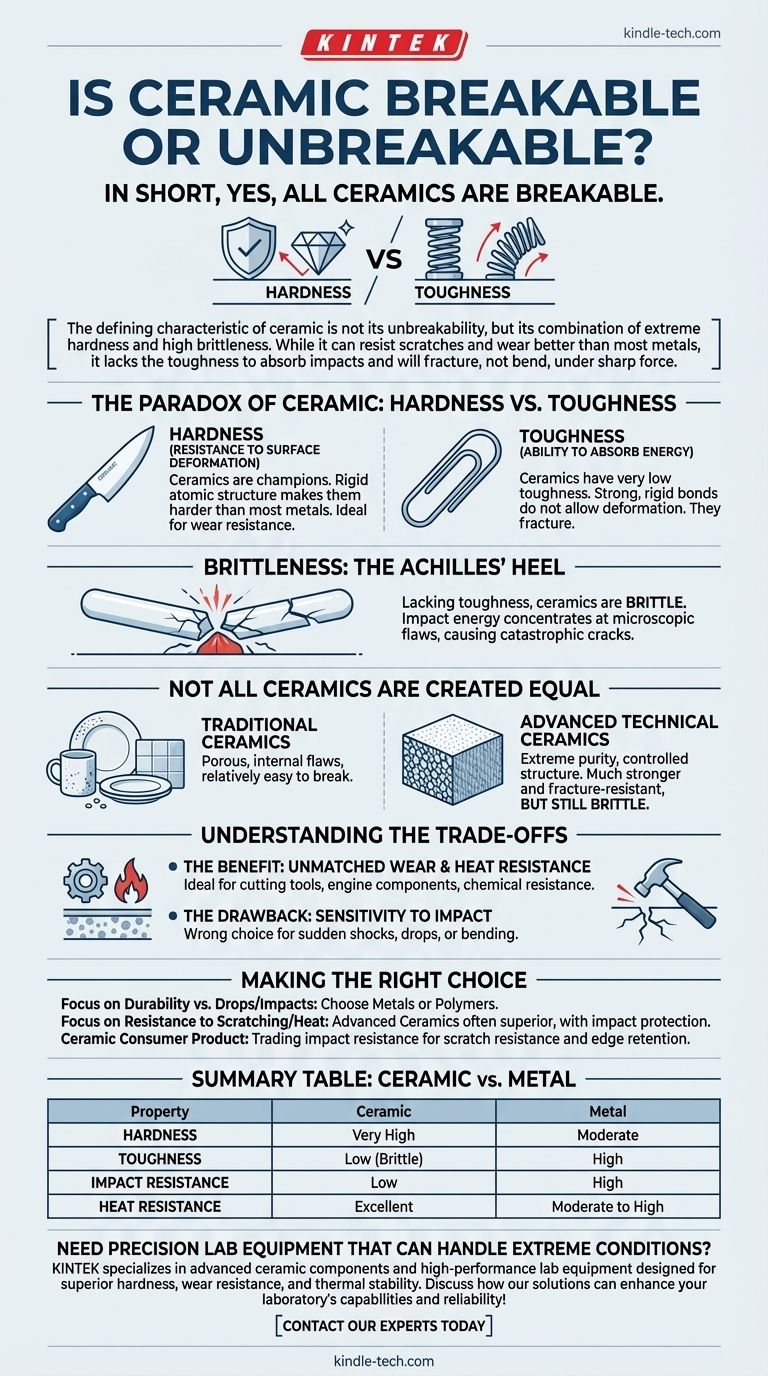

The Paradox of Ceramic: Hardness vs. Toughness

The confusion around ceramic strength stems from misunderstanding two distinct material properties: hardness and toughness. Ceramic excels at one but is defined by its lack of the other.

What "Hardness" Really Means

Hardness is a measure of a material's resistance to surface deformation, like scratching, abrasion, or indentation.

On this front, ceramics are champions. Their rigid atomic structure makes them significantly harder than even the strongest steels. This is why a ceramic watch face remains pristine for years and a ceramic knife holds its edge far longer than a metal one.

The Definition of "Toughness"

Toughness is the ability of a material to absorb energy and deform without fracturing. Think of a metal paperclip—you can bend it back and forth because the metal is tough. It deforms before it breaks.

Ceramics have very low toughness. Their atomic bonds are so strong and rigid that they don't allow for this kind of deformation.

Brittleness: The Achilles' Heel

Because they lack toughness, ceramics are brittle. When enough force is applied, especially a sudden, sharp impact, the material doesn't bend—it simply fractures.

This happens because the impact energy has nowhere to go. Instead of causing atoms to slide past each other as they would in a metal, the energy concentrates at microscopic flaws inherent in the material and creates a catastrophic crack.

Not All Ceramics Are Created Equal

The term "ceramic" covers a vast range of materials, from a simple clay pot to an advanced spacecraft component. Their properties differ dramatically.

Traditional Ceramics (Pottery, Porcelain)

These are the ceramics of everyday life: coffee mugs, dinner plates, and decorative tiles. They are typically made from natural clays and fired in a kiln.

While porcelain is denser and stronger than earthenware, all traditional ceramics contain numerous pores and internal flaws that make them relatively easy to break. This is the experience that leads us to think of all ceramic as fragile.

Advanced Technical Ceramics (Zirconia, Silicon Carbide)

This is where the reputation for "unbreakable" strength originates. Materials like zirconia (used in dental implants and some knives) or silicon carbide (used in body armor and car brakes) are engineered with extreme purity and a controlled microscopic structure.

These materials are orders of magnitude stronger and more fracture-resistant than traditional pottery. However, they are still brittle. A zirconia knife will shatter if you use it to pry something open, and a ceramic armor plate is designed to fracture to absorb the energy of a projectile.

Understanding the Trade-offs

Choosing a material is always about balancing its strengths and weaknesses for a specific job. Ceramic is no different.

The Benefit: Unmatched Wear and Heat Resistance

You choose ceramic when your primary concern is preventing scratches, chemical corrosion, and deformation under extreme heat. It is an ideal material for industrial cutting tools, engine components, and brake discs.

The Drawback: Sensitivity to Impact

Ceramic is the wrong choice for any application that will experience sudden shocks, drops, or bending forces. You would not make a hammer or a spring from ceramic, as it would fail instantly and without warning.

Ceramic Coatings: A Hybrid Approach

Products like "ceramic-coated" cookware or car waxes apply a micro-thin layer of hard ceramic material over a tougher substrate (like aluminum or paint).

This gives you the surface benefits of ceramic—scratch resistance and non-stick properties—while the underlying material provides the structural integrity and toughness needed to resist dents and impacts. The coating itself can still be chipped or scratched off.

Making the Right Choice for Your Application

Answering whether ceramic is the "right" material depends entirely on the goal.

- If your primary focus is durability against drops and impacts: Choose materials with high toughness, like metals (steel, aluminum) or certain polymers. Ceramic is a poor choice here.

- If your primary focus is resistance to scratching, abrasion, or high heat: Advanced ceramics are often the superior choice, provided you can engineer the system to protect them from sharp impacts.

- If you are considering a "ceramic" consumer product (like a knife or watch): Understand that you are trading impact resistance for exceptional, long-lasting scratch resistance and edge retention.

Ultimately, understanding that ceramic's strength lies in its hardness, not its toughness, is the key to using this remarkable material effectively.

Summary Table:

| Property | Ceramic | Metal |

|---|---|---|

| Hardness | Very High | Moderate |

| Toughness | Low (Brittle) | High |

| Impact Resistance | Low | High |

| Heat Resistance | Excellent | Moderate to High |

Need precision lab equipment that can handle extreme conditions? KINTEK specializes in advanced ceramic components and high-performance lab equipment designed for superior hardness, wear resistance, and thermal stability. Whether you're developing cutting tools, high-temperature furnaces, or specialized instruments, our expertise ensures you get the right material for your application's unique demands. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and reliability!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

People Also Ask

- How do alumina ceramic tubes address technical challenges in electrochemical devices? Ensure Peak Signal Integrity.

- What is the firing temperature of alumina? Mastering the 1300°C to 1700°C Range for Optimal Results

- How are ceramics used in medicine? Unlocking Biocompatible Implants for Long-Term Health

- Which ceramic materials are most widely used? A Guide to Alumina, Zirconia, SiC, and Si3N4

- What are the characteristics of sintered ceramics? Achieve High-Performance with Engineered Materials

- What is the purpose of adding yttria to zirconia? Master High-Performance Ceramic Stability and Strength

- Why is it necessary to use sintering aids for PLS? Achieve Full Density in Ultra-High Temperature Ceramics

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers