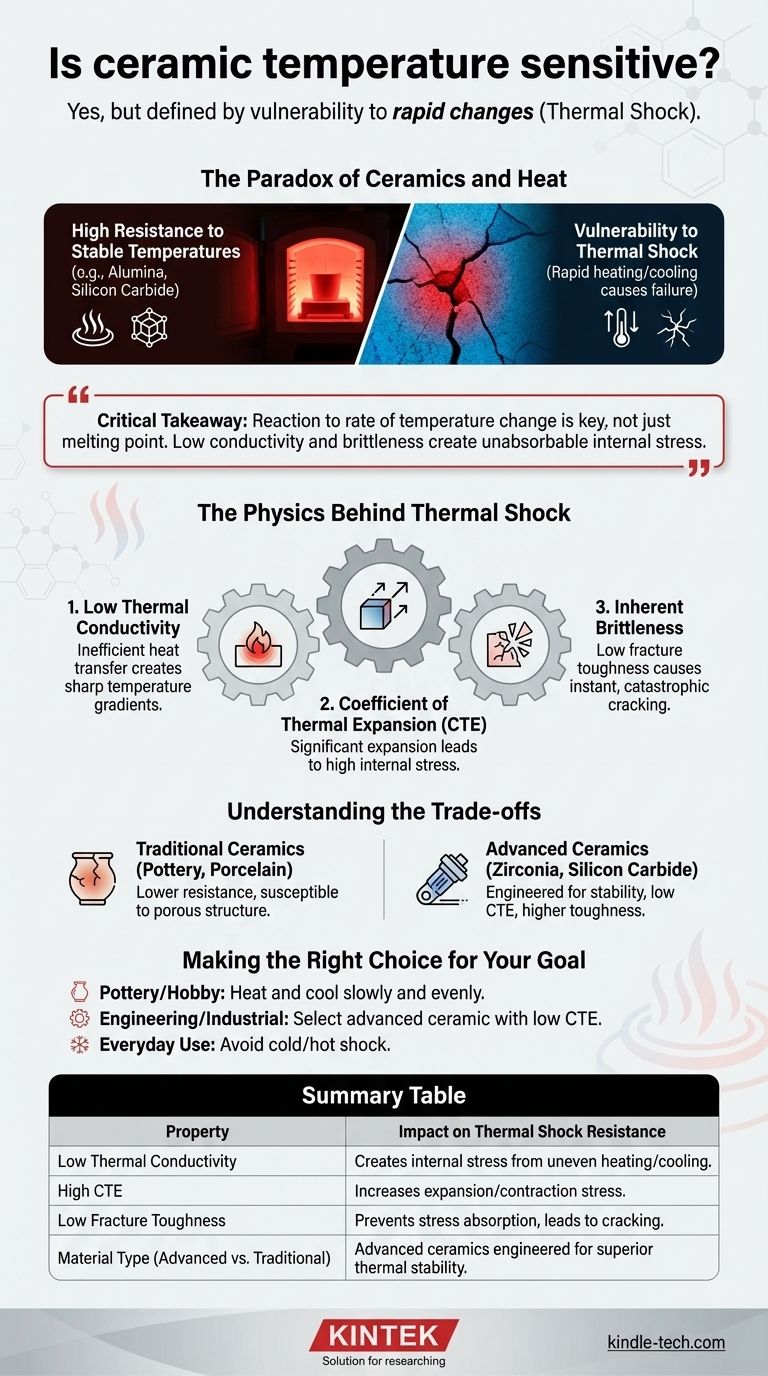

Yes, all ceramics are sensitive to temperature, but their sensitivity is defined by their extreme vulnerability to rapid changes in temperature, a phenomenon known as thermal shock. While they can withstand incredibly high, stable heat, their internal structure cannot tolerate the stress of sudden expansion or contraction, which often leads to cracking and catastrophic failure.

The critical takeaway is that a ceramic's sensitivity to temperature is not about its melting point, but about its reaction to the rate of temperature change. Its low thermal conductivity and brittle nature mean that fast heating or cooling creates internal stress that the material cannot absorb, causing it to break.

The Dual Nature of Ceramics and Heat

Ceramics present a paradox. They are used in applications requiring immense heat resistance, like furnaces and engine components, yet they can shatter if their temperature changes too quickly. Understanding this duality is key.

High Resistance to Stable Temperatures

Most technical ceramics, such as alumina and silicon carbide, have exceptionally high melting points, often far exceeding those of metals.

This property allows them to remain strong and stable at temperatures that would cause other materials to weaken, melt, or deform. This is why they are used as insulators in kilns, as heat shields on spacecraft, and in industrial furnaces.

The True Weakness: Rapid Change (Thermal Shock)

Thermal shock is the primary failure mode for ceramics exposed to temperature fluctuations.

When a ceramic is heated or cooled rapidly, one part of the material changes temperature—and thus size—faster than another. This differential creates immense internal stress. Because ceramics are brittle, they cannot bend or deform to relieve this stress, so they crack instead.

The Physics Behind Thermal Shock

Three core material properties work together to make ceramics susceptible to thermal shock. A change in any of these properties can dramatically improve or worsen a ceramic's performance.

1. Low Thermal Conductivity

Ceramics are excellent thermal insulators, meaning they do not transfer heat efficiently.

When you apply heat to one spot, that spot gets very hot while adjacent areas remain cool. This sharp temperature gradient is the root cause of the differential expansion that creates stress.

2. Coefficient of Thermal Expansion (CTE)

Like all materials, ceramics expand when heated and contract when cooled. The measure of how much they expand for each degree of temperature change is their Coefficient of Thermal Expansion (CTE).

A high CTE means the material expands and contracts significantly. When combined with poor heat conduction, this leads to high internal stress during temperature changes.

3. Inherent Brittleness

Unlike metals, which can plastically deform (bend) under stress, ceramics are rigid and brittle.

They have very low fracture toughness, meaning that once a microscopic crack forms due to thermal stress, it will propagate almost instantly through the material, causing a complete fracture. There is no "graceful failure."

Understanding the Trade-offs: Not All Ceramics Are Equal

The term "ceramic" covers a vast range of materials, from earthenware pottery to advanced, engineered composites. Their temperature sensitivity varies significantly.

Traditional Ceramics (Pottery, Porcelain, Earthenware)

These materials generally have a lower resistance to thermal shock.

Their chemical composition and often porous microstructure make them more susceptible to damage from rapid heating or cooling. A glaze on a ceramic body can also cause issues if its CTE does not perfectly match the CTE of the clay body, leading to cracking or "crazing."

Technical & Advanced Ceramics (Zirconia, Silicon Carbide, Alumina)

These materials are specifically engineered for thermal stability. They are designed to have very low CTEs, higher thermal conductivity, or enhanced fracture toughness.

For example, materials like fused silica and lithium aluminosilicates (used in high-end ceramic cookware) have a near-zero CTE, making them exceptionally resistant to thermal shock.

Making the Right Choice for Your Goal

Your approach to managing a ceramic's temperature sensitivity depends entirely on your application, whether you are a potter, an engineer, or simply using ceramic cookware.

- If your primary focus is pottery or hobby ceramics: Your goal is to prevent cracking during firing and use. Always heat and cool pieces as slowly and evenly as possible to minimize thermal gradients.

- If your primary focus is engineering or industrial design: Your goal is material selection. Choose an advanced ceramic with a low CTE and high fracture toughness specifically rated for the thermal cycles of your application.

- If your primary focus is everyday use (e.g., cookware): Your goal is proper handling. Never expose a hot ceramic dish to a cold shock (like cold water or a granite countertop) or vice-versa.

Mastering a ceramic's relationship with heat is about controlling the rate of change, not just the absolute temperature.

Summary Table:

| Property | Impact on Thermal Shock Resistance |

|---|---|

| Low Thermal Conductivity | Creates internal stress from uneven heating/cooling. |

| High Coefficient of Thermal Expansion (CTE) | Increases the amount of expansion/contraction, raising stress. |

| Low Fracture Toughness (Brittleness) | Prevents stress absorption, leading to cracking. |

| Material Type (Traditional vs. Advanced) | Advanced ceramics are engineered for superior thermal stability. |

Need a ceramic that can withstand extreme thermal cycles in your lab or process? KINTEK specializes in high-performance lab equipment and consumables. Our expertise in advanced ceramics like alumina and silicon carbide ensures you get materials with the optimal thermal shock resistance for your specific application. Contact our experts today to find the perfect solution for your laboratory's high-temperature needs.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is the process of alumina tube manufacturing? From Powder to High-Performance Ceramic

- How long does ceramic fiber last? Maximize Lifespan from Months to Decades

- What is another advantage of using ceramics over metals for tooth crowns? Eliminate Temperature Sensitivity and Allergies

- What are the classification of ceramic materials? A Guide to Oxides, Non-Oxides, and Composites

- What are the synthesis methods of SiC? From Industrial Abrasives to High-Performance Electronics

- How to decrease porosity in aluminum oxide? Master Powder & Sintering for Maximum Density

- What is another name for dental ceramic? Discover the Porcelain & Modern Material Options

- Why is silicon carbide more efficient? Unlock Higher Power Density with SiC's Superior Material Properties