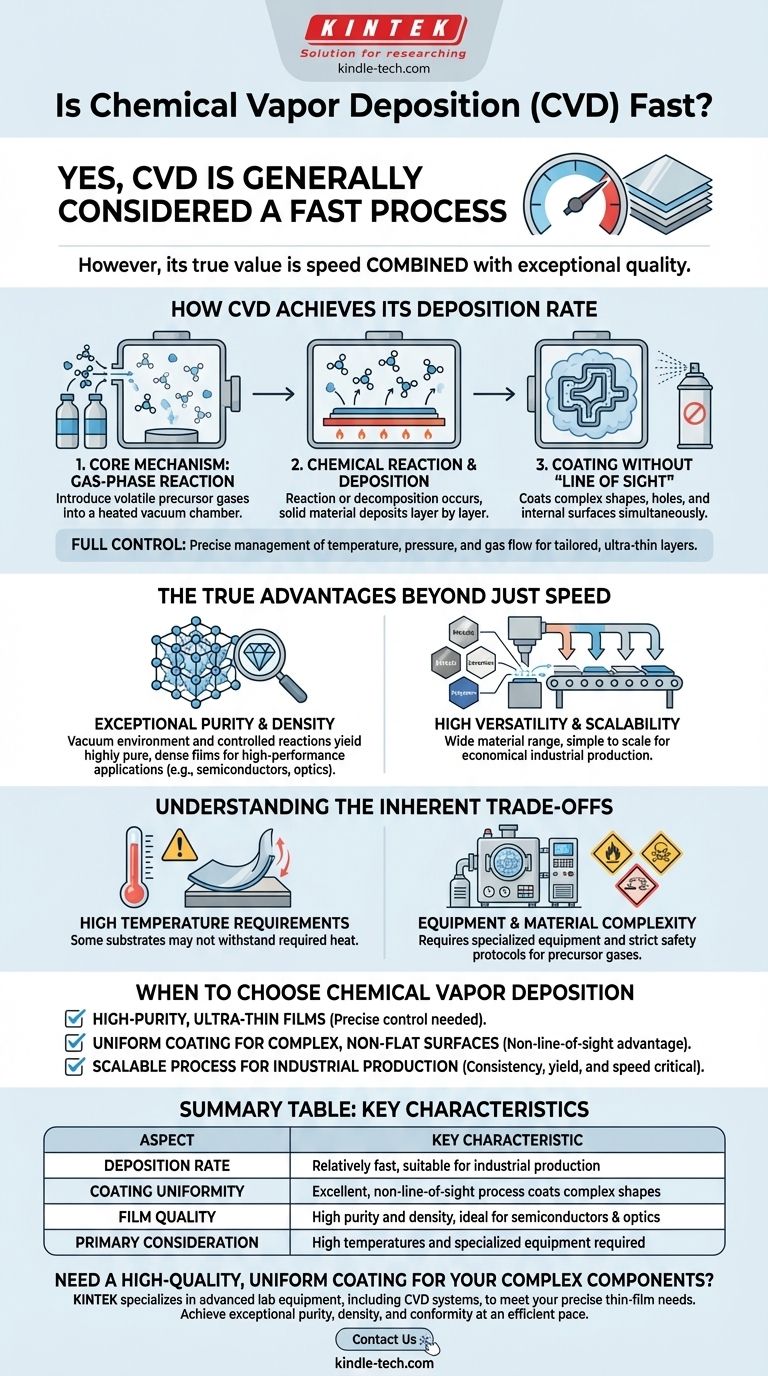

Yes, Chemical Vapor Deposition (CVD) is generally considered a fast process, offering comparatively high deposition rates for producing thin films. Its true value, however, is not just its speed but its ability to combine this rate with exceptional purity, density, and uniformity, even on complex surfaces.

The key takeaway is that while CVD offers impressive speed for a thin-film deposition process, its primary advantage is achieving that speed without compromising the quality, purity, and conformity of the final coating.

How CVD Achieves Its Deposition Rate

Chemical Vapor Deposition is fundamentally a process of building a material layer by layer from a chemical reaction. This unique mechanism is the source of both its speed and its precision.

The Core Mechanism: A Gas-Phase Reaction

The process begins by introducing one or more volatile precursor gases into a vacuum chamber containing the object to be coated, known as the substrate.

When the chamber is heated, a chemical reaction is triggered. The precursor gases react or decompose, and the resulting solid material is deposited uniformly onto the heated substrate surface.

This continuous chemical reaction allows for a steady and relatively rapid build-up of the desired thin film.

Coating Without "Line of Sight"

Unlike many physical deposition methods that work like spray painting, CVD is a non-line-of-sight process.

The precursor gas fills the entire chamber, allowing the chemical reaction to occur on all exposed surfaces of the substrate simultaneously. This makes CVD highly efficient for coating components with complex shapes, holes, and internal surfaces.

Full Control Over the Process

Engineers have complete control over the key variables in the CVD process, such as temperature, pressure, and gas flow rates.

This allows for precise management of the deposition rate and the ability to create ultra-thin, highly pure layers tailored for specific applications, like those found in electrical circuits.

The True Advantages Beyond Just Speed

While the deposition rate is a significant benefit, the reasons engineers choose CVD often have more to do with the quality of the resulting film.

Exceptional Purity and Density

The vacuum environment and controlled chemical reactions result in films that are highly pure and dense. This is critical for applications in semiconductors, optics, and other high-performance fields where material imperfections can cause failure.

High Versatility and Scalability

Because the process is driven by chemical reactions, it is incredibly versatile and can be used to deposit a wide range of materials, from metals and ceramics to polymers.

The principles of CVD are also simple to scale up, which, combined with a high manufacturing yield, makes it a viable and economical choice for industrial production.

Understanding the Inherent Trade-offs

No process is perfect, and CVD's advantages come with practical considerations. Being aware of these trade-offs is crucial for making an informed decision.

High Temperature Requirements

Many CVD processes require very high temperatures to initiate the necessary chemical reactions. This can limit the types of substrate materials that can be used, as some may not withstand the heat without deforming or melting.

Equipment and Material Complexity

CVD requires specialized and often expensive equipment, including vacuum chambers, heating systems, and gas handling controls.

Furthermore, the precursor gases can be toxic, flammable, or corrosive, requiring stringent safety protocols and handling procedures.

When to Choose Chemical Vapor Deposition

Selecting the right manufacturing process depends entirely on your project's specific goals.

- If your primary focus is high-purity, ultra-thin films: CVD is an ideal choice due to its precise control over the deposition process.

- If you need to coat complex, non-flat surfaces uniformly: The non-line-of-sight nature of CVD makes it superior to many alternative methods.

- If you require a scalable process for industrial production: CVD is well-suited for manufacturing environments where consistency, yield, and a relatively high deposition rate are critical.

Ultimately, CVD is the technology of choice when you need to produce a high-quality, uniform coating at an efficient, industrial pace.

Summary Table:

| Aspect | Key Characteristic |

|---|---|

| Deposition Rate | Relatively fast, suitable for industrial production |

| Coating Uniformity | Excellent, non-line-of-sight process coats complex shapes |

| Film Quality | High purity and density, ideal for semiconductors & optics |

| Primary Consideration | High temperatures and specialized equipment required |

Need a high-quality, uniform coating for your complex components?

KINTEK specializes in providing advanced lab equipment, including Chemical Vapor Deposition systems, to meet your precise thin-film needs. Our solutions are designed to help you achieve exceptional purity, density, and conformity at an efficient pace.

Contact us today to discuss how our expertise can enhance your laboratory's capabilities and production yield!

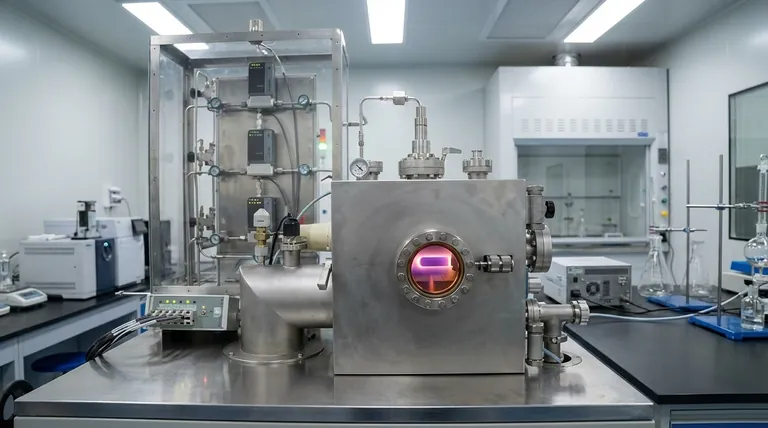

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained