Yes, absolutely. Heat treatment is a fundamental and critical set of processes in metallurgy used to intentionally alter the physical, and sometimes chemical, properties of a metal alloy. By carefully controlling heating and cooling cycles, metallurgists can manipulate the alloy's internal microstructure to achieve specific and predictable engineering outcomes.

The core principle of heat treatment is not about changing the metal's chemical composition, but about rearranging its internal crystal structure. This controlled manipulation allows you to transform a single alloy into a material that can be soft and formable, incredibly hard and wear-resistant, or tough and durable.

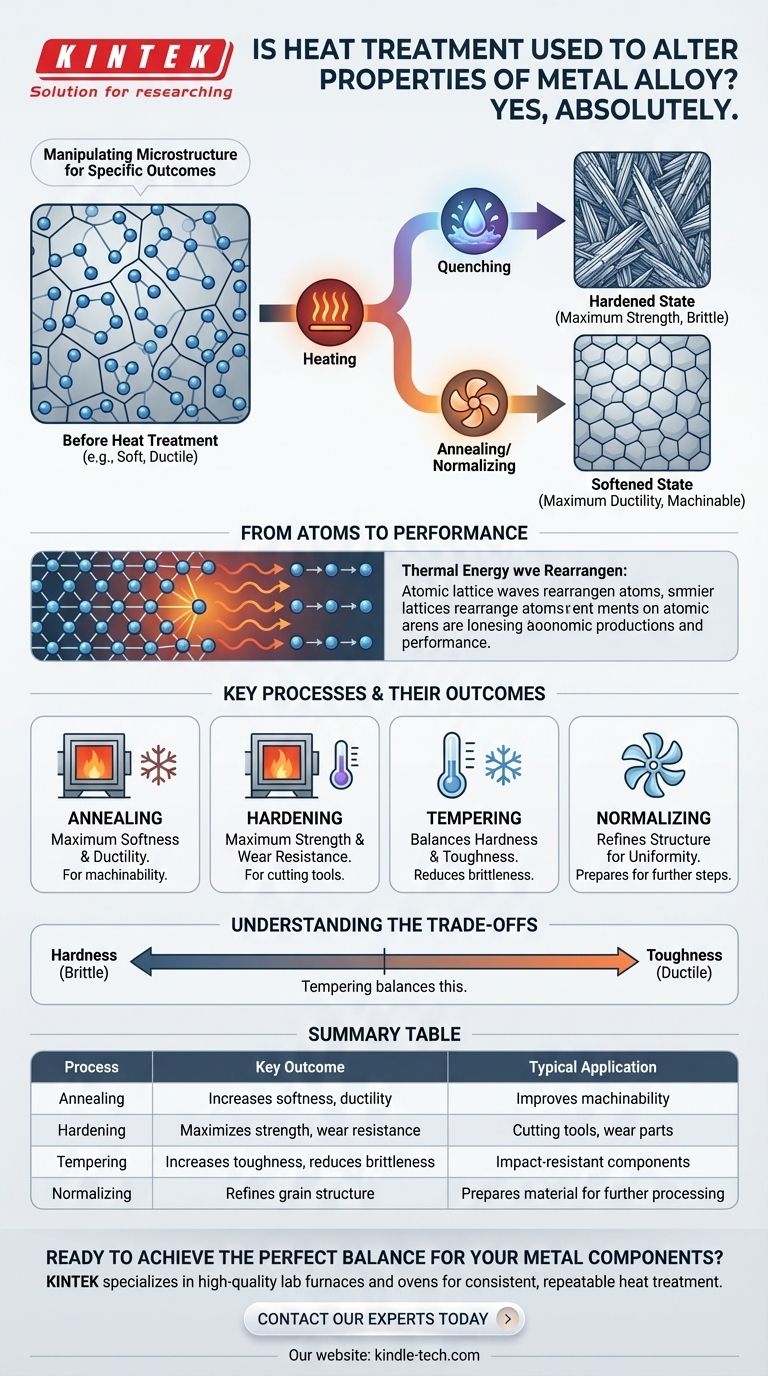

The "Why" Behind Heat Treatment: Manipulating Microstructure

The performance of any metal alloy is dictated by its microstructure—the specific arrangement and size of its crystalline grains. Heat treatment is the primary tool used to control this internal architecture.

The Role of Temperature

Heating a metal alloy provides the thermal energy necessary for atoms within the crystal lattice to move and rearrange. As the temperature rises past a critical point, the existing crystal structures can dissolve and transform into new, different structures.

The Importance of Cooling (Quenching)

The rate at which the metal is cooled is just as important as the temperature it was heated to. A rapid cooling process, known as quenching, can "trap" high-temperature crystal structures at room temperature. Slower cooling allows the atoms more time to rearrange into different, often softer, structures.

From Atoms to Performance

Think of the alloy's atoms as building blocks. Heat treatment allows you to break down their existing arrangement and then, through controlled cooling, reassemble them into a new structure with entirely different properties. A fine, needle-like structure might be very hard, while a coarse, blocky structure might be much softer and more ductile.

Key Heat Treatment Processes and Their Outcomes

Different combinations of heating, holding, and cooling create distinct outcomes tailored to specific applications.

Annealing: For Maximum Softness

Annealing involves heating the metal and then cooling it very slowly. This process relieves internal stresses, increases ductility, and makes the metal significantly softer and easier to machine or form.

Hardening: For Maximum Strength

Hardening is achieved by heating the alloy to a high temperature and then cooling it very rapidly (quenching), often in water, oil, or air. This traps a very hard but brittle microstructure, ideal for applications requiring high wear resistance and strength, like cutting tools.

Tempering: Finding the Balance

A hardened part is often too brittle for practical use. Tempering is a secondary, lower-temperature heat treatment performed after hardening. It slightly reduces hardness but significantly increases the material's toughness, preventing it from fracturing under impact.

Normalizing: Refining the Structure

Normalizing involves heating the metal and then letting it cool in open air. This process is often used to refine the grain structure after a forming operation, creating a more uniform and predictable material to prepare it for subsequent hardening.

Understanding the Trade-offs

Choosing a heat treatment process is always a matter of balancing competing properties. There is no single "best" state for an alloy.

The Hardness vs. Toughness Compromise

This is the most fundamental trade-off. Increasing a material's hardness almost always makes it more brittle (less tough). The purpose of tempering is to deliberately sacrifice some hardness to gain the necessary toughness for an application.

Surface vs. Bulk Properties

Standard heat treatments like annealing and hardening affect the entire volume of the material—its bulk properties. In contrast, some advanced processes, like the plasma treatment you mentioned or case hardening, are designed to modify only the surface, creating a hard, wear-resistant outer layer while leaving the core tough and ductile.

The Risk of Distortion and Cracking

The extreme temperature changes involved, especially rapid quenching, can introduce significant internal stresses. This can cause parts to warp, distort, or even crack if the process is not carefully controlled for the specific alloy and part geometry.

Matching the Treatment to the Goal

The right process is entirely dependent on the desired final performance of the component.

- If your primary focus is machinability and forming: Annealing is the required process to make the material as soft and ductile as possible.

- If your primary focus is maximum wear resistance and cutting ability: Hardening is the key, but it must almost always be followed by tempering.

- If your primary focus is toughness and impact resistance: Tempering is the critical step to relieve the brittleness caused by hardening.

- If your primary focus is a uniform, consistent starting structure: Normalizing is the correct procedure to refine the grain and reset the material.

Ultimately, heat treatment is the art and science of telling a metal alloy precisely what properties it needs to have for the task at hand.

Summary Table:

| Process | Key Outcome | Typical Application |

|---|---|---|

| Annealing | Increases softness and ductility | Improves machinability and formability |

| Hardening | Maximizes strength and wear resistance | Cutting tools, wear parts |

| Tempering | Increases toughness, reduces brittleness | Impact-resistant components |

| Normalizing | Refines grain structure for uniformity | Prepares material for further processing |

Ready to achieve the perfect balance of hardness, toughness, and performance for your metal components?

The precise control required for successful heat treatment starts with reliable equipment. KINTEK specializes in high-quality lab furnaces and ovens designed for consistent, repeatable results in annealing, hardening, tempering, and more. Our solutions help metallurgists and engineers like you transform metal alloys to meet exact specifications.

Contact our experts today to discuss your specific heat treatment challenges and discover how KINTEK's equipment can enhance your process. Get in touch via our contact form to get started.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials